Structure for encapsulating semiconductor

A packaging structure, semiconductor technology, applied in the direction of semiconductor devices, semiconductor/solid-state device components, electric solid-state devices, etc., can solve difficult structural strength problems and brightness problems, negative impact on packaging pass rate, structural deformation and distortion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

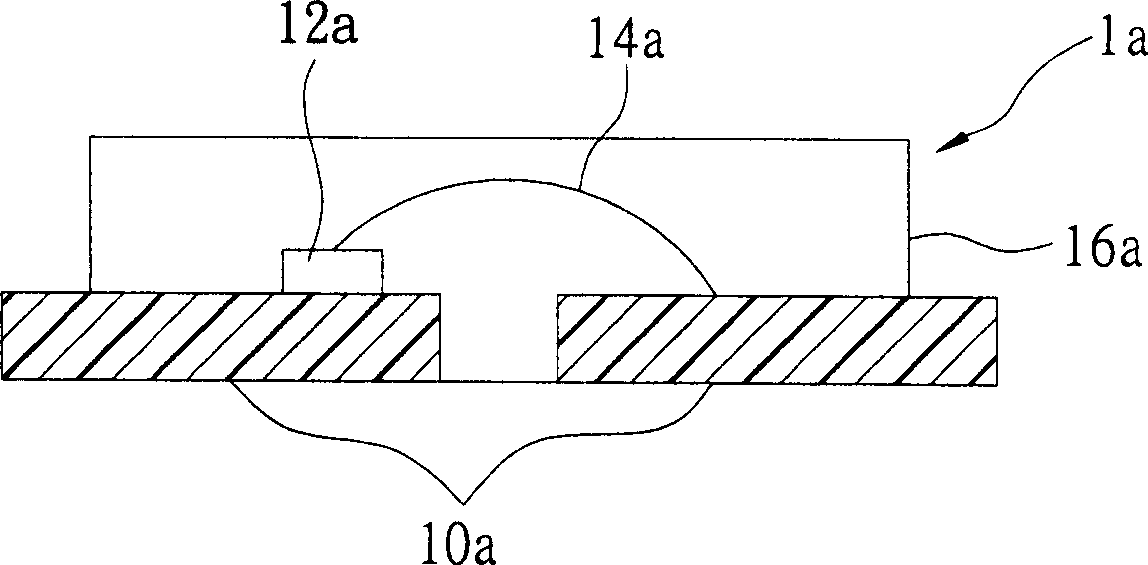

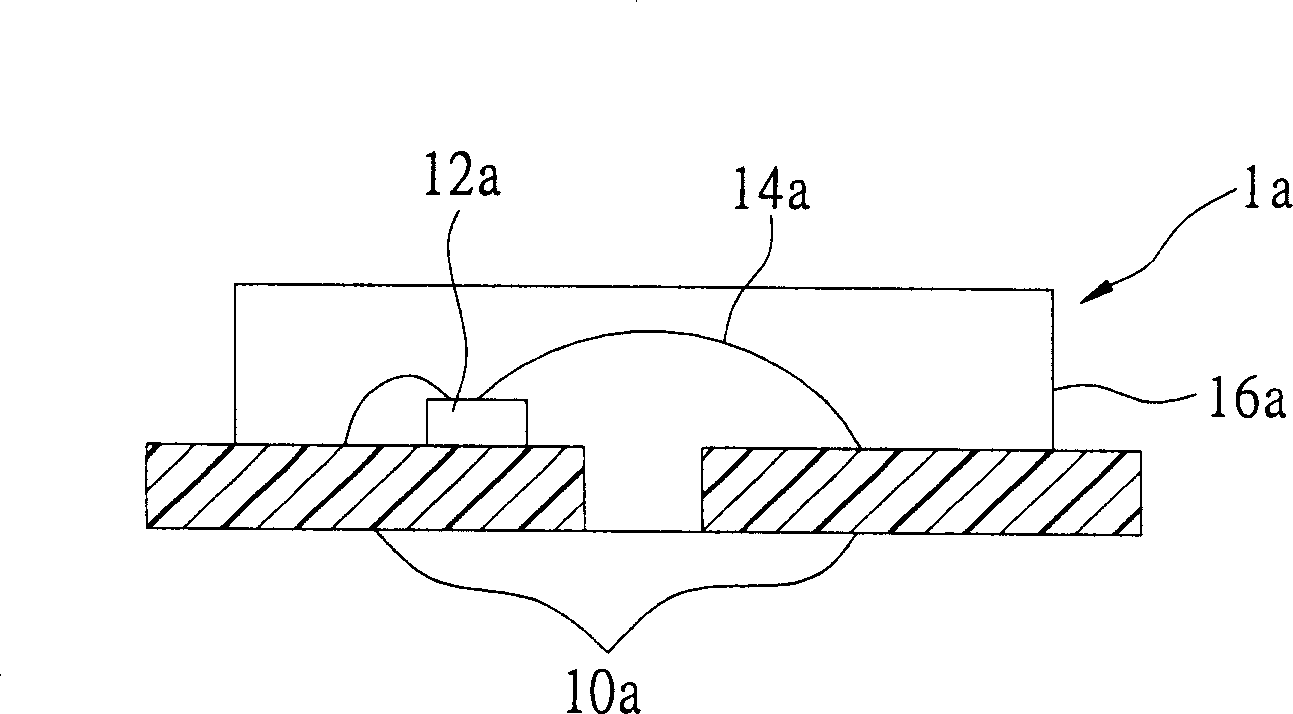

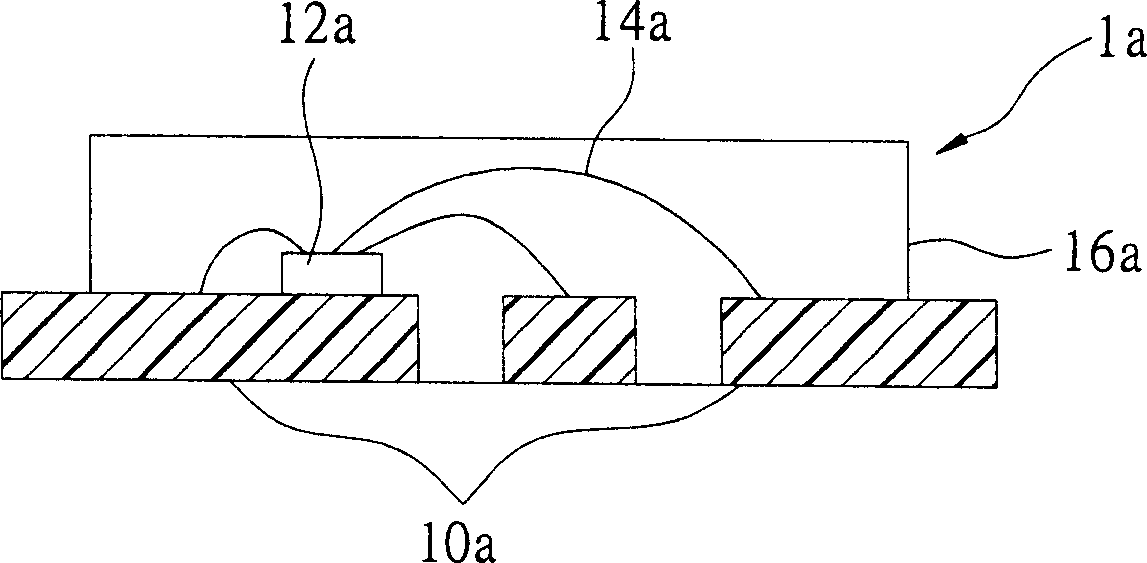

[0043] Please refer to Figure 2A to Figure 2B , where the gap is W (the middle of the substrate 10) and the thickness is H, that is, H is proportional to W, when Figure 2A The thinner the thickness of the plate, the smaller the interval can be, that is Figure 2A The thickness of each layer is 1 / 2, such as Figure 2B When the stack structure, Figure 2B The interval between thin layers can be very small to achieve the purpose of reducing the interval and strengthening the board. Therefore, according to the above-mentioned relationship between H and W, the structure of stacked layers is not necessarily 1 / 2, and can be adjusted according to actual needs.

[0044] Please refer to Figure 3A to Figure 3B , Figure 4 , Figure 5A to Figure 5E , is an embodiment of the present invention, where Figure 3A and Figure 3B For single-sided stacking, Figure 4 It is double-sided laminated, Figure 5A to Figure 5E Be the embodiment that has outer frame device 17 ( Figure 5D a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com