Liquid crystal panel testing device

A technology for a liquid crystal panel and an inspection device, which can be applied to coupling devices, parts of connecting devices, and test/measurement connectors, etc., can solve problems such as increased manufacturing costs, complicated manufacturing processes, and prolonged manufacturing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Embodiments of the present invention will be described in detail below. In addition, the scope of the present invention is not limited to this embodiment.

[0042] The liquid crystal inspection device of the present invention will be described based on the drawings and the following embodiments.

[0043] Embodiments of the present invention will be described below with reference to the drawings. Additionally, with Figure 8 to Figure 13 Partly the same components or components having the same functions are given the same symbols.

[0044] The liquid crystal panel inspection device of the present invention is configured in the same manner as the conventional device in terms of the overall connection system except for the structure of the components.

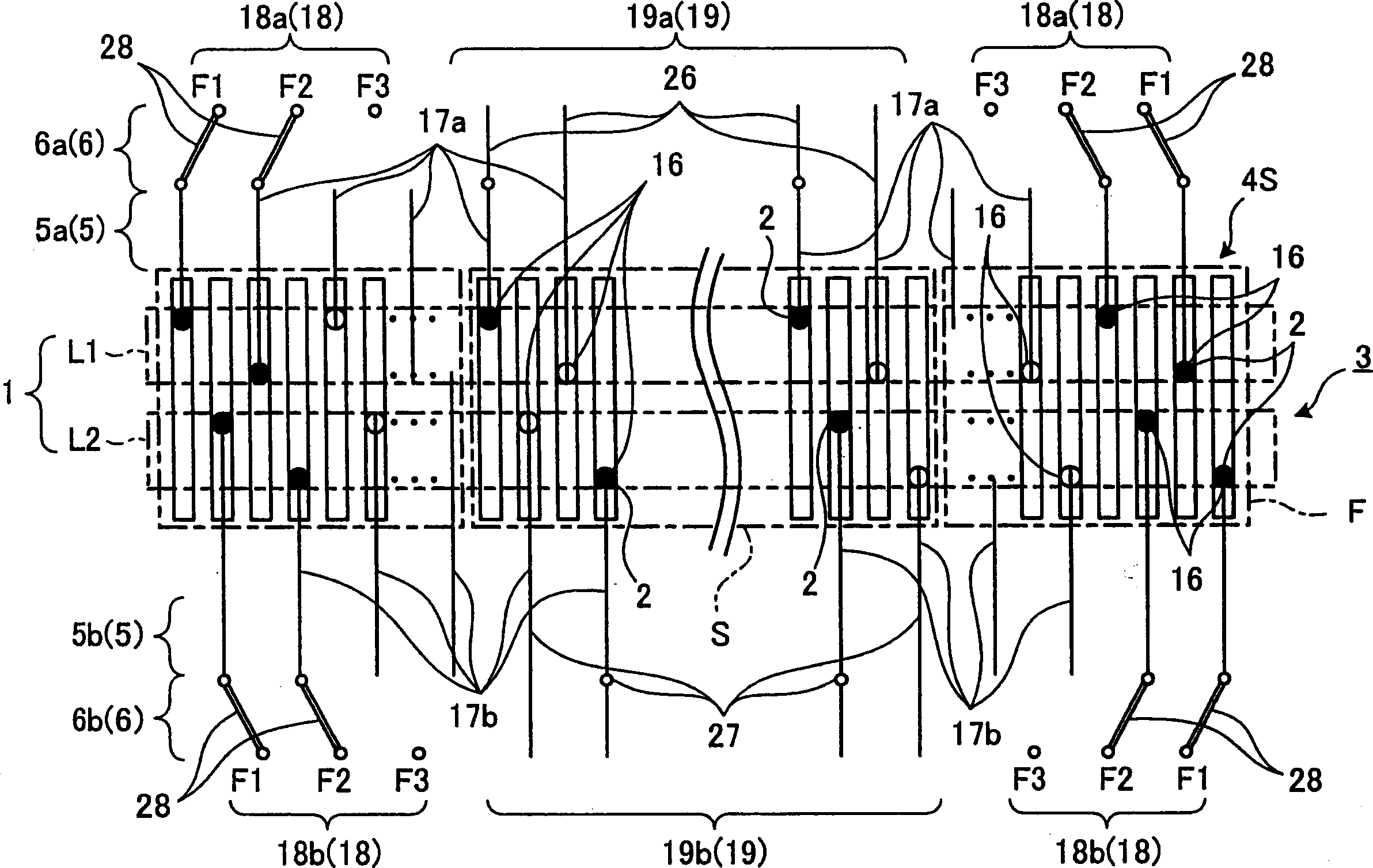

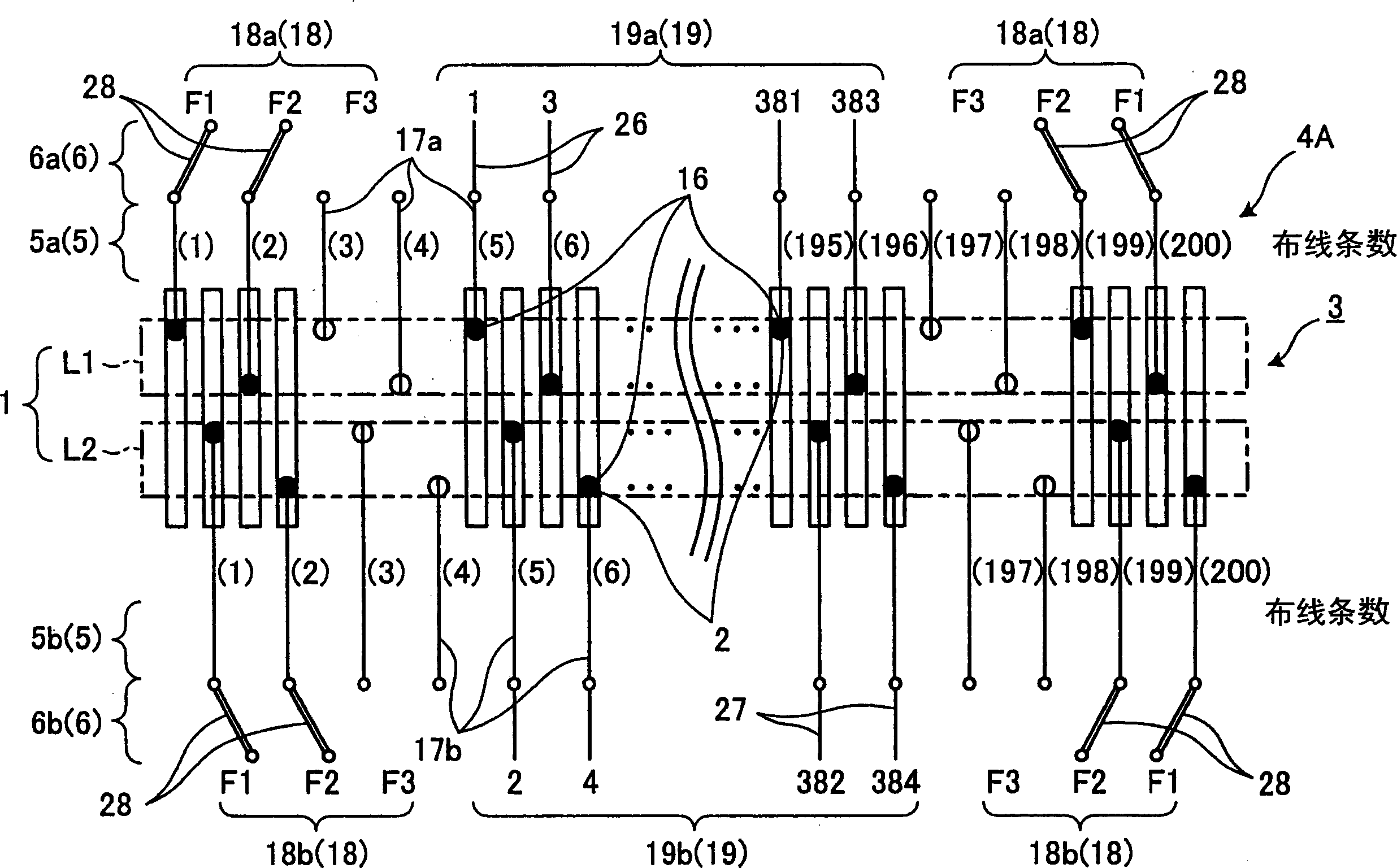

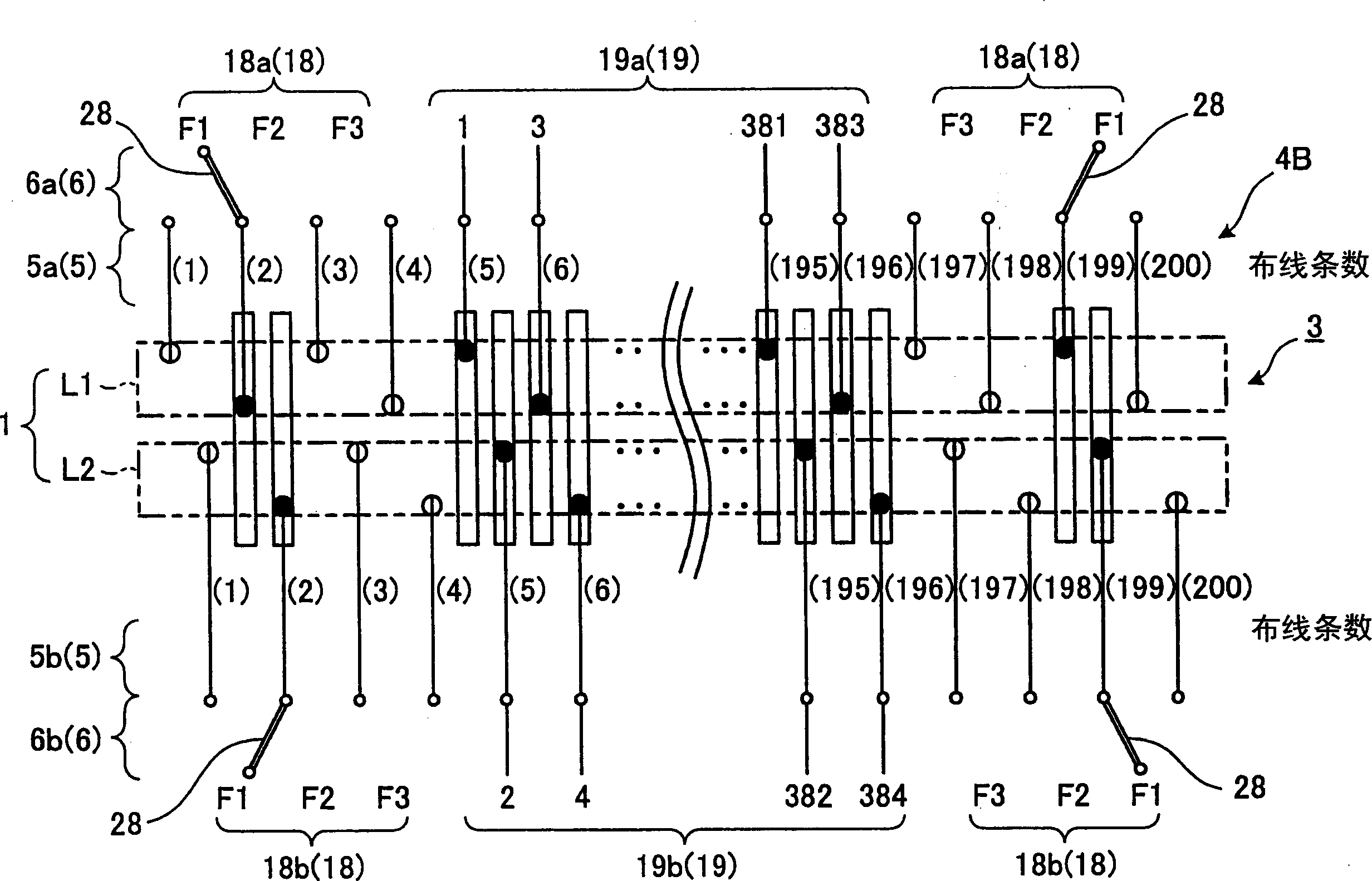

[0045] That is, if Figure 8 As shown, the overall connection system applicable to the general liquid crystal panel inspection device of the present invention is structurally such that the probes 2 of the probe block 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com