Sediment incrustation distributor

A distributor and fouler technology, which is applied in the field of fouling distributors, can solve the problems of excessively fast increase of the pressure drop of the reactor, affecting the efficiency and operation cycle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

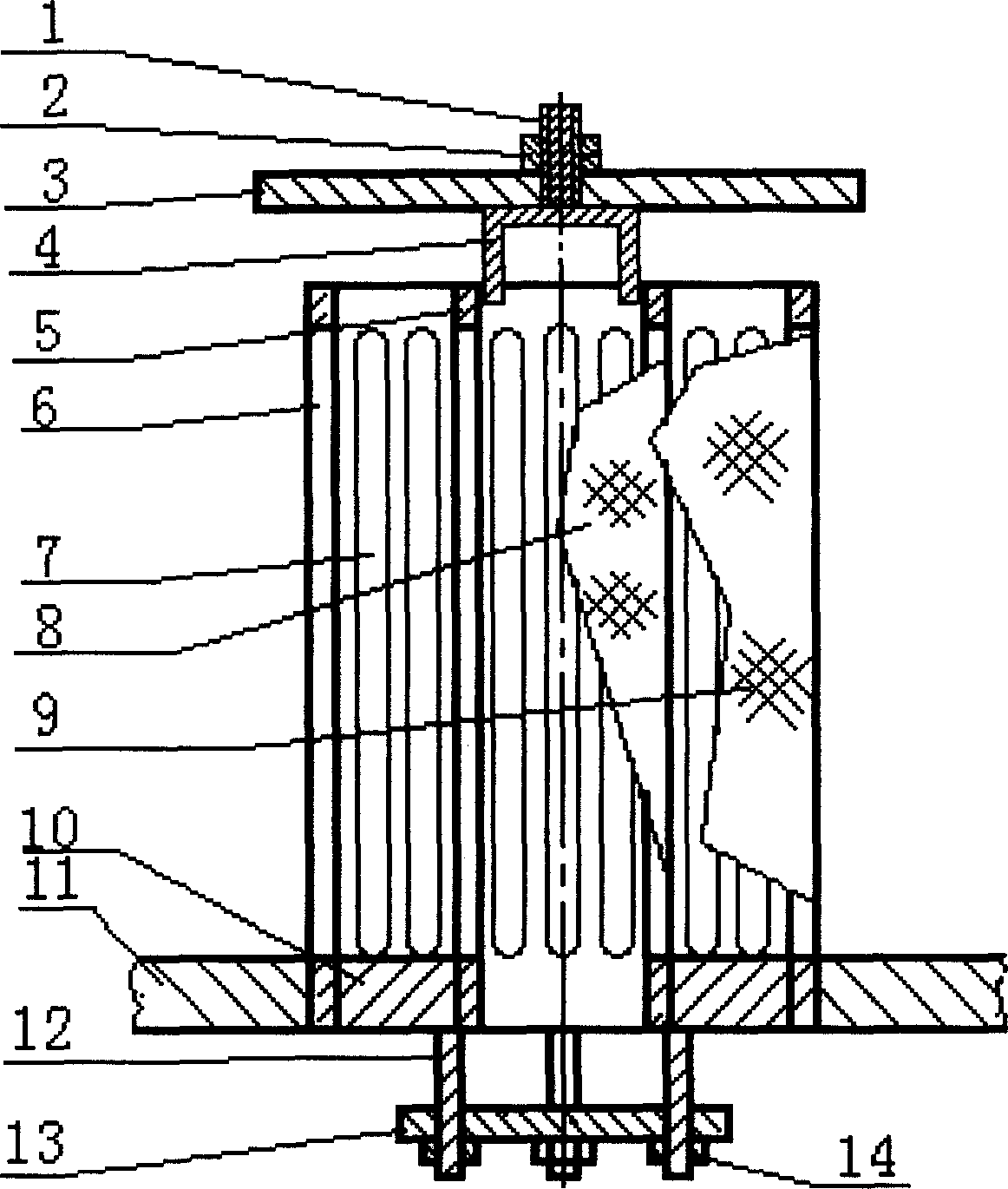

[0017] A fouling distributor of a typical structure of the present invention and its mode of operation will be further described below in conjunction with the accompanying drawings.

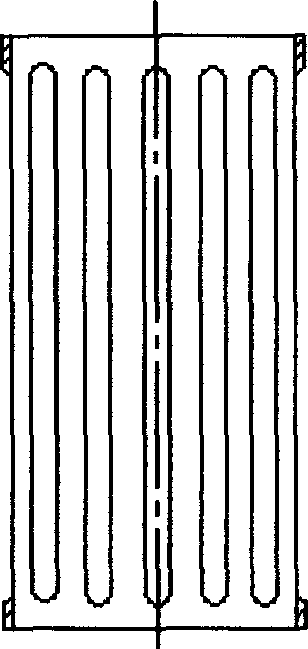

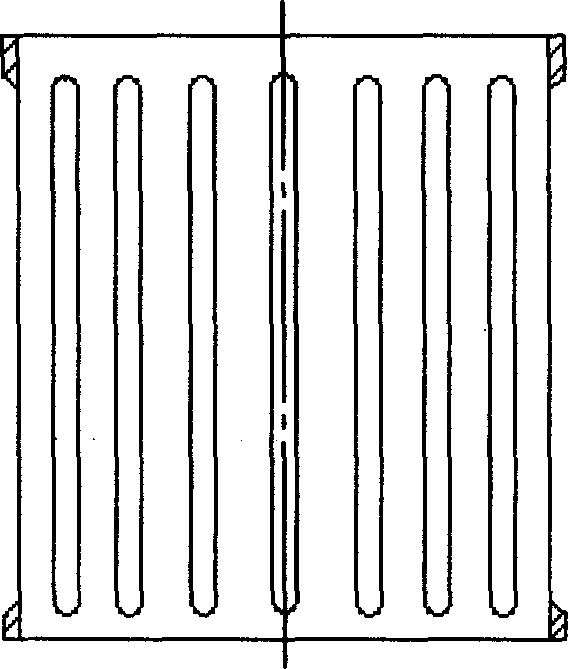

[0018] Such as figure 1 As shown, the fouling distributor of the present invention is composed of connecting bolt 1, connecting nut 2, baffle plate 3, connecting frame 4, fouling device inner tube skeleton 5, fouling device outer tube skeleton 6, elongated hole 7, inner tube Filter screen 8, outer tube filter screen 9, sealing bottom plate 10, distribution bottom plate etc. 11, broken flow plate tie bars 12, broken flow plate 13, tie bar nut 14 form. Wherein the fouling device inner cylinder frame 5 and the fouling device outer barrel skeleton 6 are surrounded by filter screens 8 and 9, fillers or protective agents are installed between the fouling device inner barrel 5 and the fouling device outer barrel 6, and baffles 3 The top of the top is provided with a central hole and is connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com