Novel punch head

A punch, a new type of technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of affecting the efficiency of processing and rising processing costs, and achieve the effect of easy replacement and non-damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing, the present invention is further described:

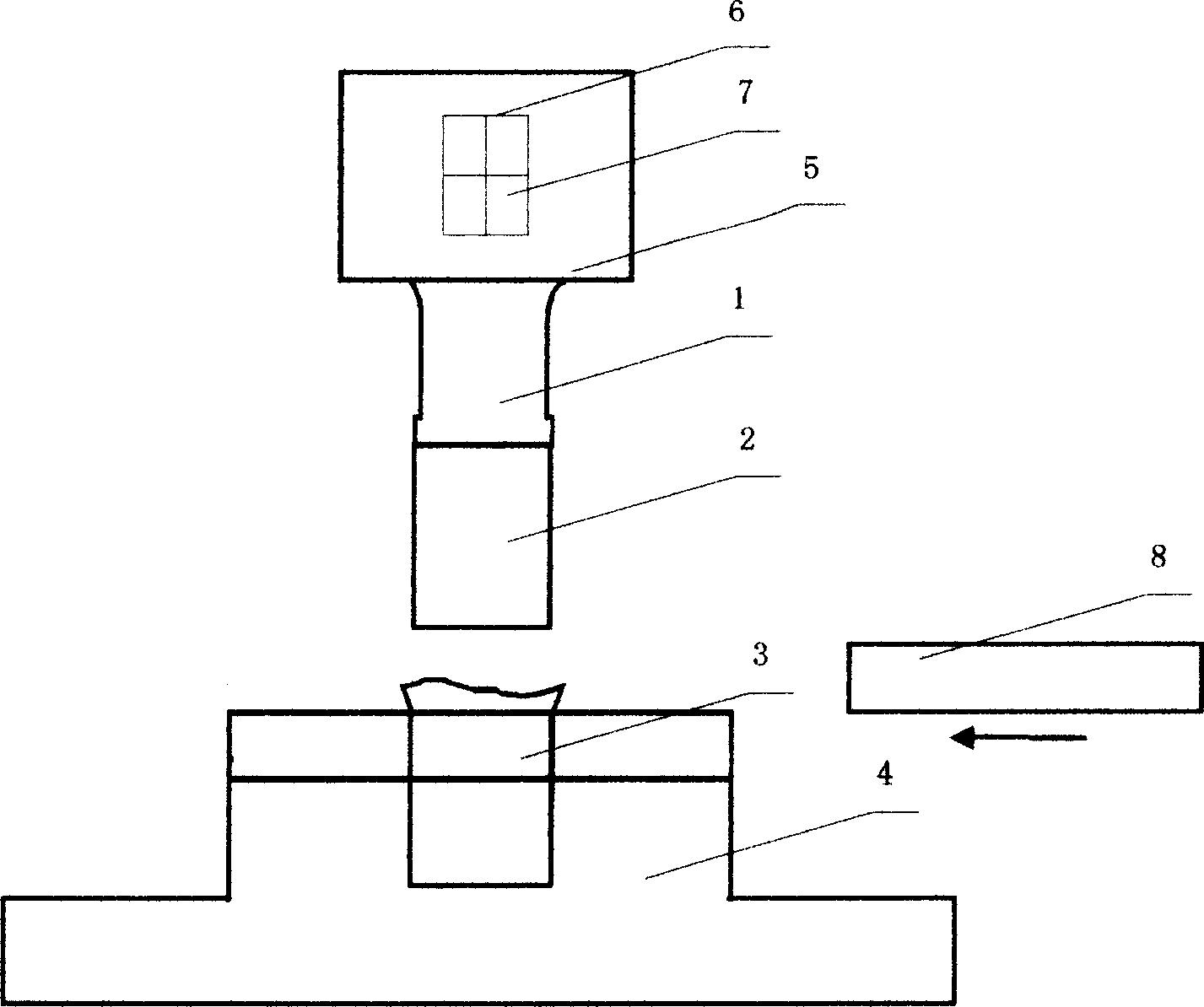

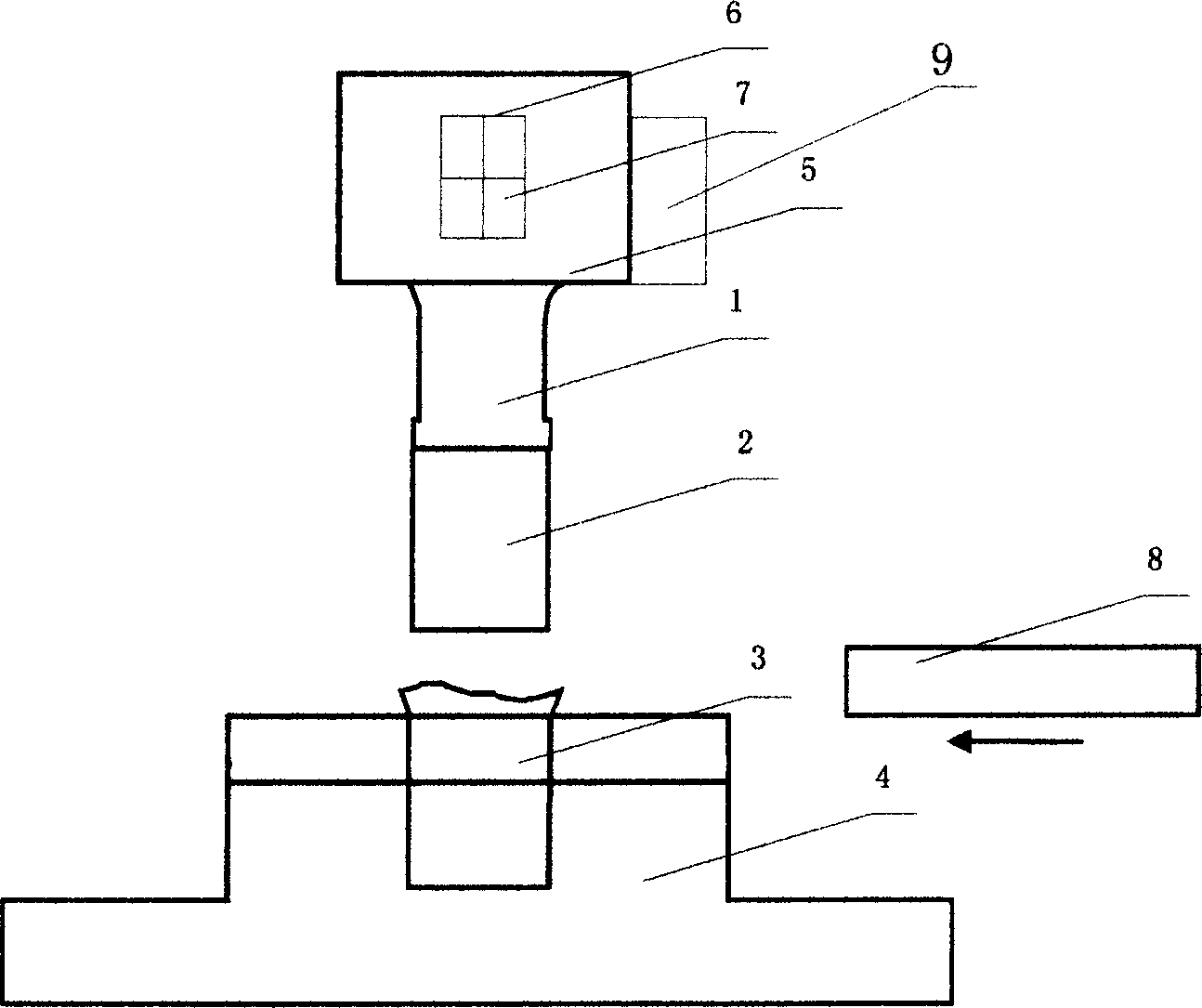

[0010] Such as figure 1 The middle is a specific embodiment of the present invention. A square hole 6 is provided in the punch holder 5, a permanent magnet 7 is installed in the hole, and a punch 1 is fixed under the punch holder 5. Because the punch holder 5 is affected by the permanent magnet 7, the magnetic force is concentrated on the end of the punch 1. The shear core 2 used for positioning during cutting is placed on the end of the punch 1 and is magnetically adsorbed on the punch 1 . On the working table of the punching machine, a lower mold base 4 is installed, and the middle part of the lower mold base 4 is a square counterbore with a shape corresponding to the shape of the workpiece, which is used to place the workpiece. Riser. Now the punch 2 is just above the square counterbore on the lower die base 4 . After placing the workpiece 3 in the above-mentioned squar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com