Holding tool for a processing head in a laser processing machine with several anti-colliding elements having means for adjusting the loosening load

A technology of laser processing machine and laser processing head, which is applied in the direction of metal processing machinery parts, auxiliary devices, laser welding equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

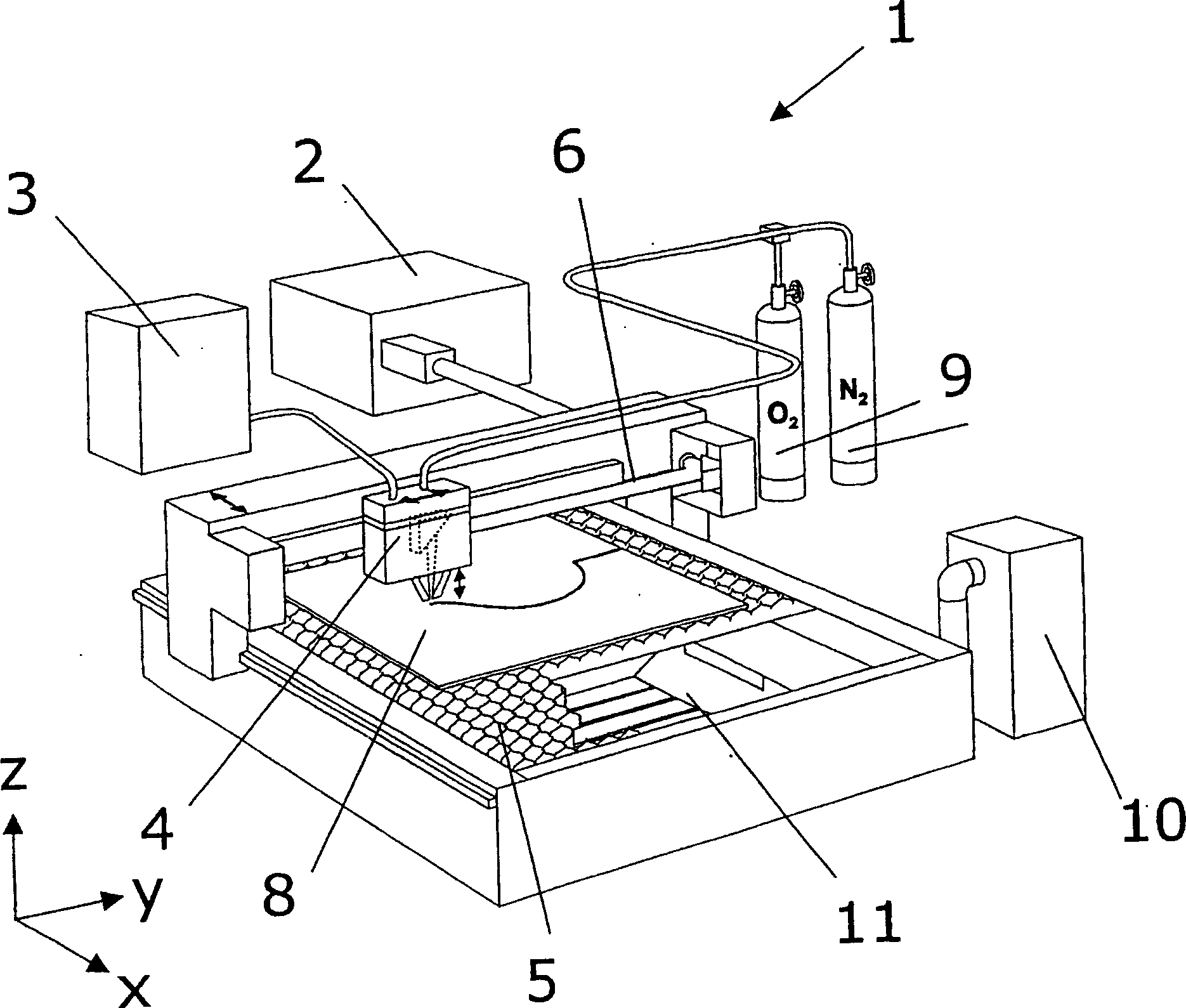

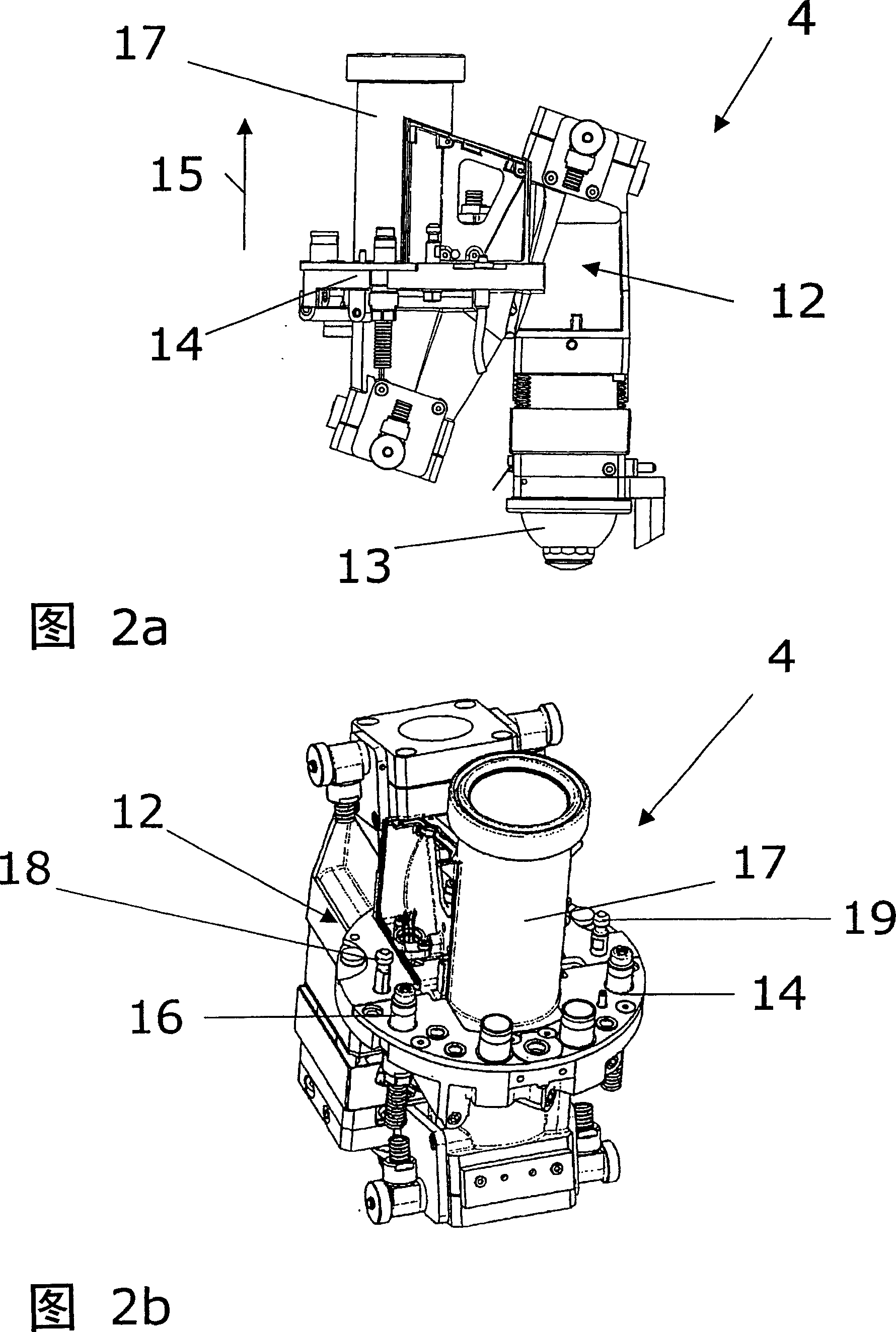

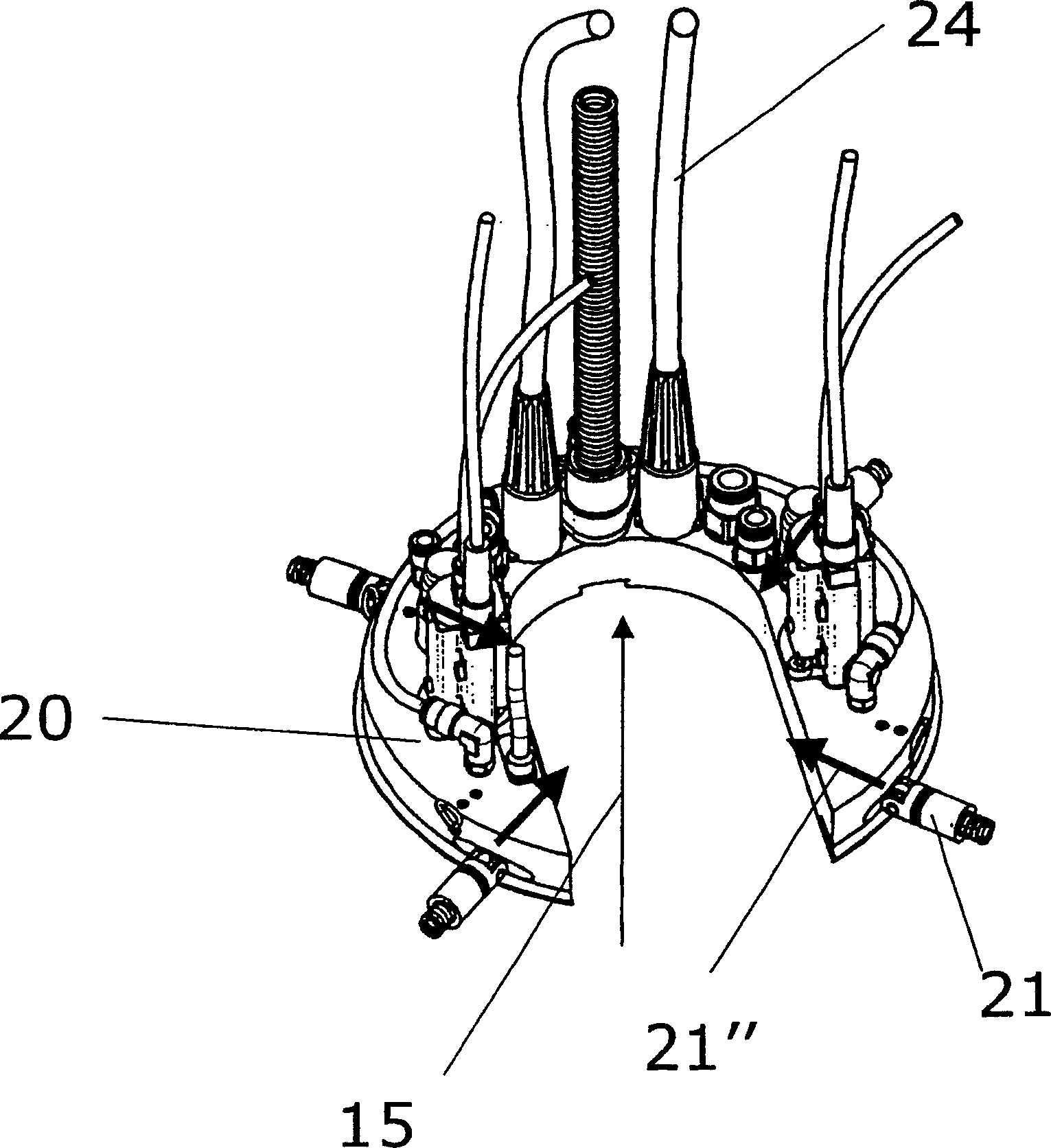

[0019] Depend on figure 1 The basic structure of a laser processing plant 1 for laser cutting with a CO 2 Laser 2, a control device 3, a laser processing head 4 and a workpiece support 5. A generated laser beam 6 is directed onto the laser processing head 4 and directed onto the workpiece 8 by means of deflection mirrors.

[0020] The laser beam 6 must penetrate the workpiece 8 before forming the usual cutting seam. The metal plate 8 must be melted or oxidized in spots at one point and the melt must be blown out. The piercing process can be performed quickly (ie with full laser power) or slowly (via a so-called "ramp").

[0021] When piercing at a slow speed with a ramp, the laser power can be gradually increased-decreased and kept constant in a certain time interval until the pierced hole is produced. Both piercing and laser cutting are assisted by the addition of a gas. Oxygen, nitrogen, compressed air and / or, depending on the application, special gases can be used as c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com