Magnetostriction instrument

A technology of magnetostriction and test solution, which is applied to instruments, scientific instruments, measuring devices, etc., and can solve problems such as cavitation of materials that cannot be measured

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

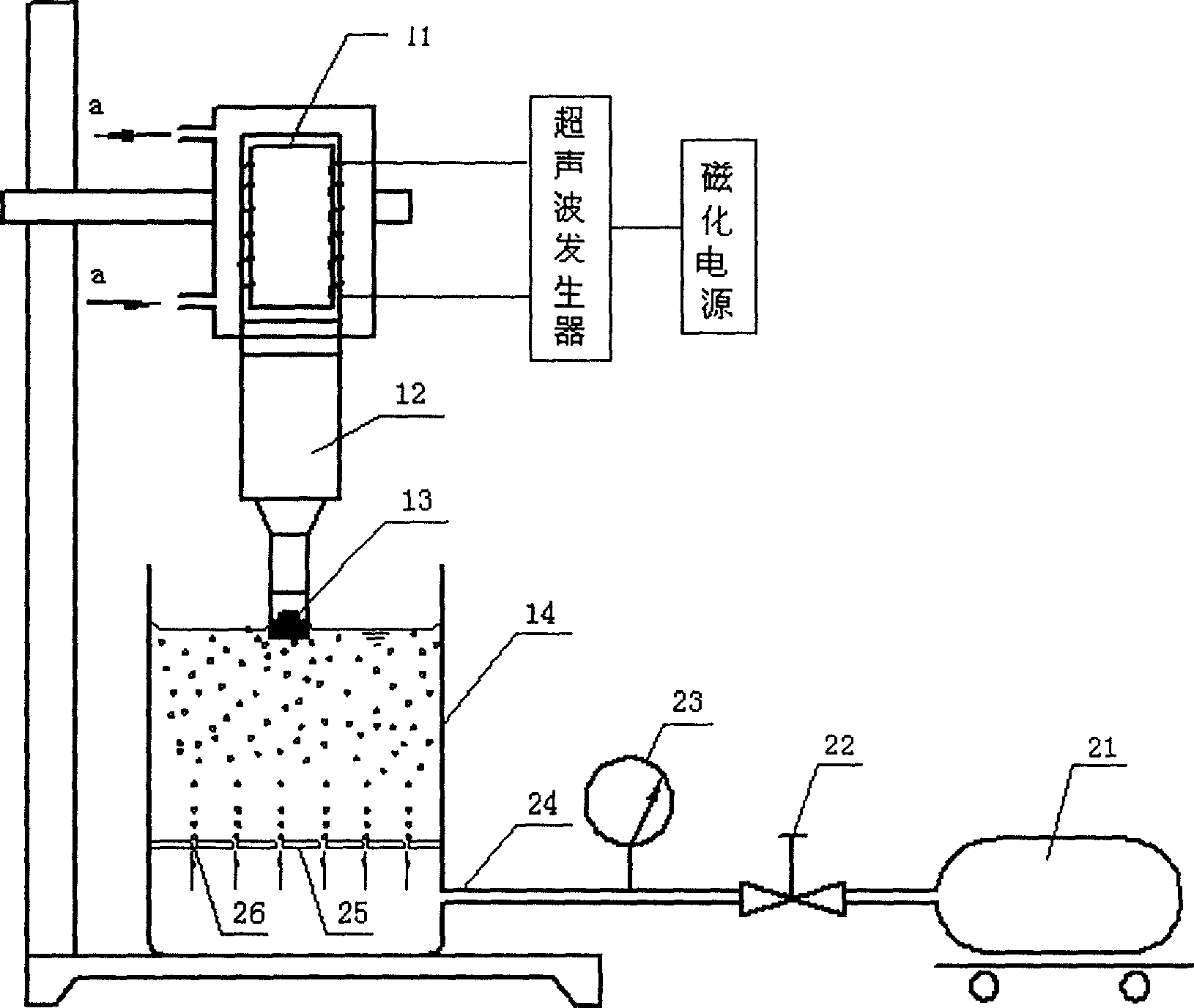

[0032] The air hole plate is made of plexiglass with a thickness of 3 mm, the air hole diameter is 0.15 mm, the opening rate is 49%, and the plum blossom shape is arranged.

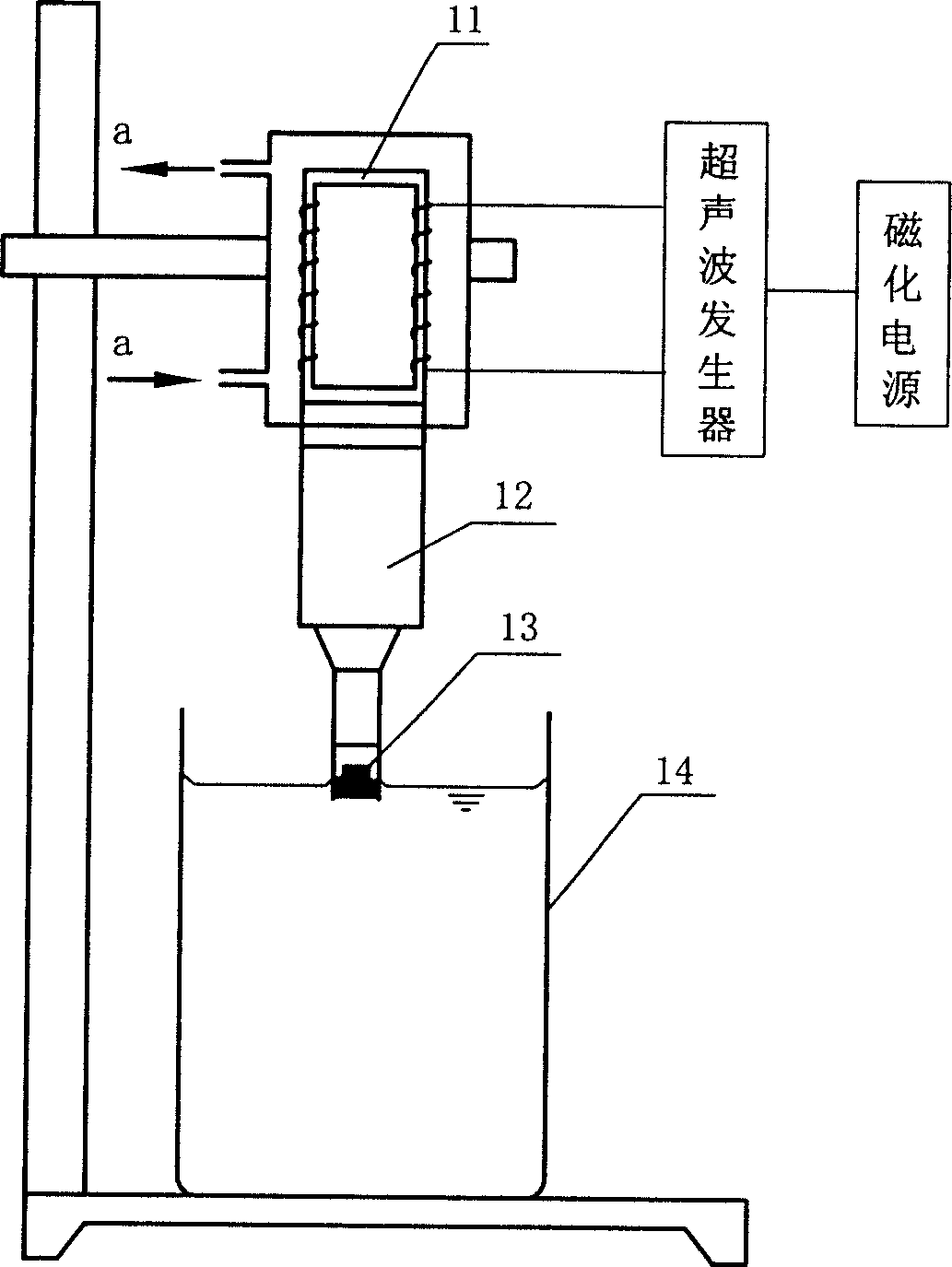

[0033] The vibration frequency of the magnetostrictive instrument used in this embodiment is 19.3kHz, the amplitude is 50 μm, and the power is 1000W. The test piece is OCr13Ni9Ti stainless steel, and the test solution used is water, such as figure 2 As shown, add water in the container 14 that test solution is housed in the magnetostrictive instrument of the present invention, the test piece 13 is contained in the lower end of the magnetostrictive instrument horn 12, adjusts the height of the test piece 13, makes the test piece 13 just immerse 3mm in the water, start the magnetostrictive instrument to make the test piece 13 axially vibrate at high frequency in the water. Since the vibration frequency of the magnetostrictive instrument is 19.3kHz, the amplitude is 50μm, and the power is 1000W, the vibratio...

Embodiment 2

[0037] The sample material used in this embodiment is CrMnN stainless steel that has undergone solid-liquid treatment at 1000°C + tempering heat treatment at 600°C. Test method and test condition are exactly the same as embodiment one.

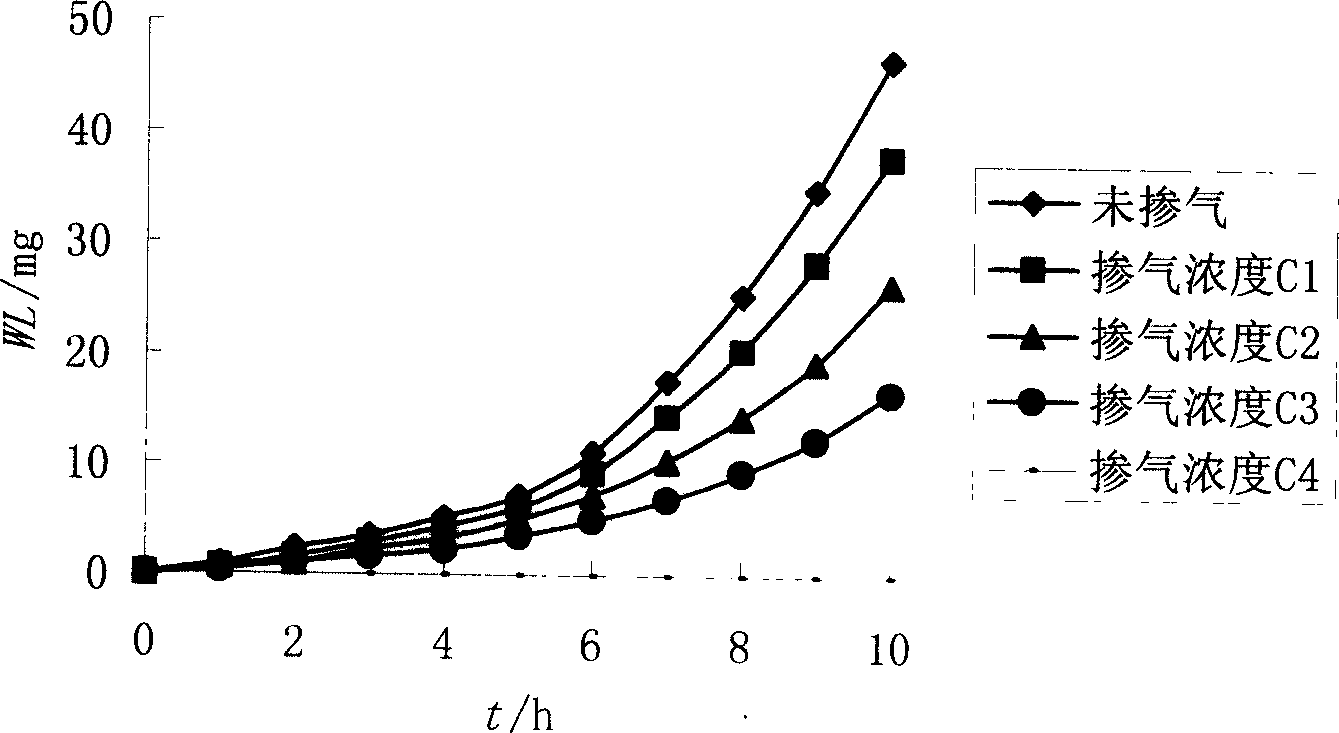

[0038] According to the measured data of the test, the relationship curve between the mass loss of the test piece and the gas concentration and test time is made, see Figure 4 . The air pressures are respectively P1, P2, P3, and P4, and the aeration concentration values C1<C2<C3<C4 are the same as in the first embodiment. The critical non-corrosion gas concentration value CX2 under this experimental condition can be obtained by interpolating enough times of experiments between C3 and C4.

[0039] In actual engineering, use the equipment of the same material as the test piece and operate under the same working conditions as the test conditions. As long as the aeration concentration at the contact surface between the equipment and the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com