Cpp-type giant manetoresistance effect element and magnetic component and magnetic device using it

A giant magnetoresistance element and magnetic technology, applied in the field of giant magnetoresistance effect elements, magnetic components and magnetic devices, can solve the problem of small resistance change ΔR and magnetoresistance change rate, small current path of CPP-GMR element, and hindrance of CPP-GMR Issues such as component availability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Below, according to Figure 1 ~ Figure 1 9 to describe in detail the best implementation of the present invention. In the drawings, the same symbols are used for the same or corresponding parts.

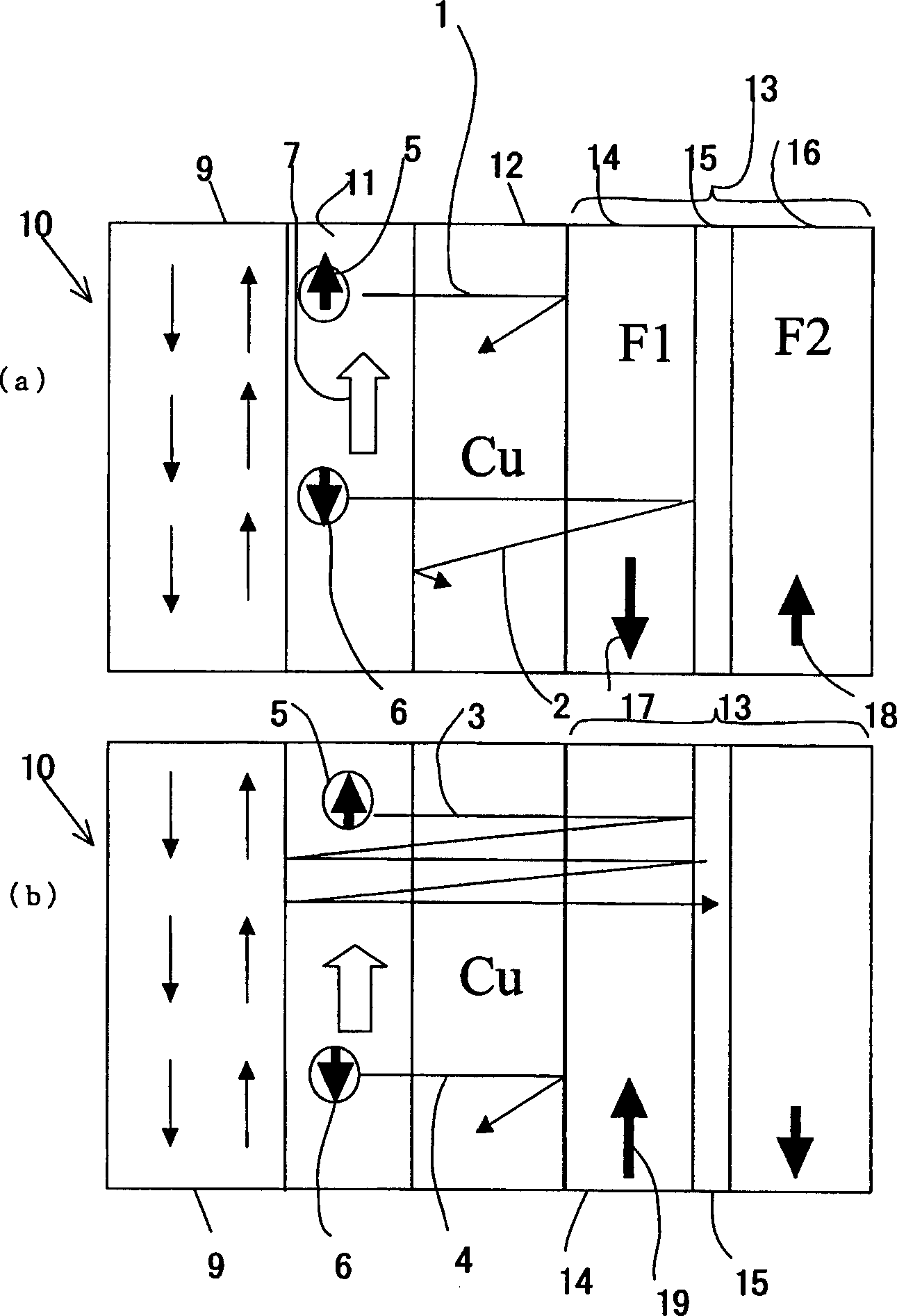

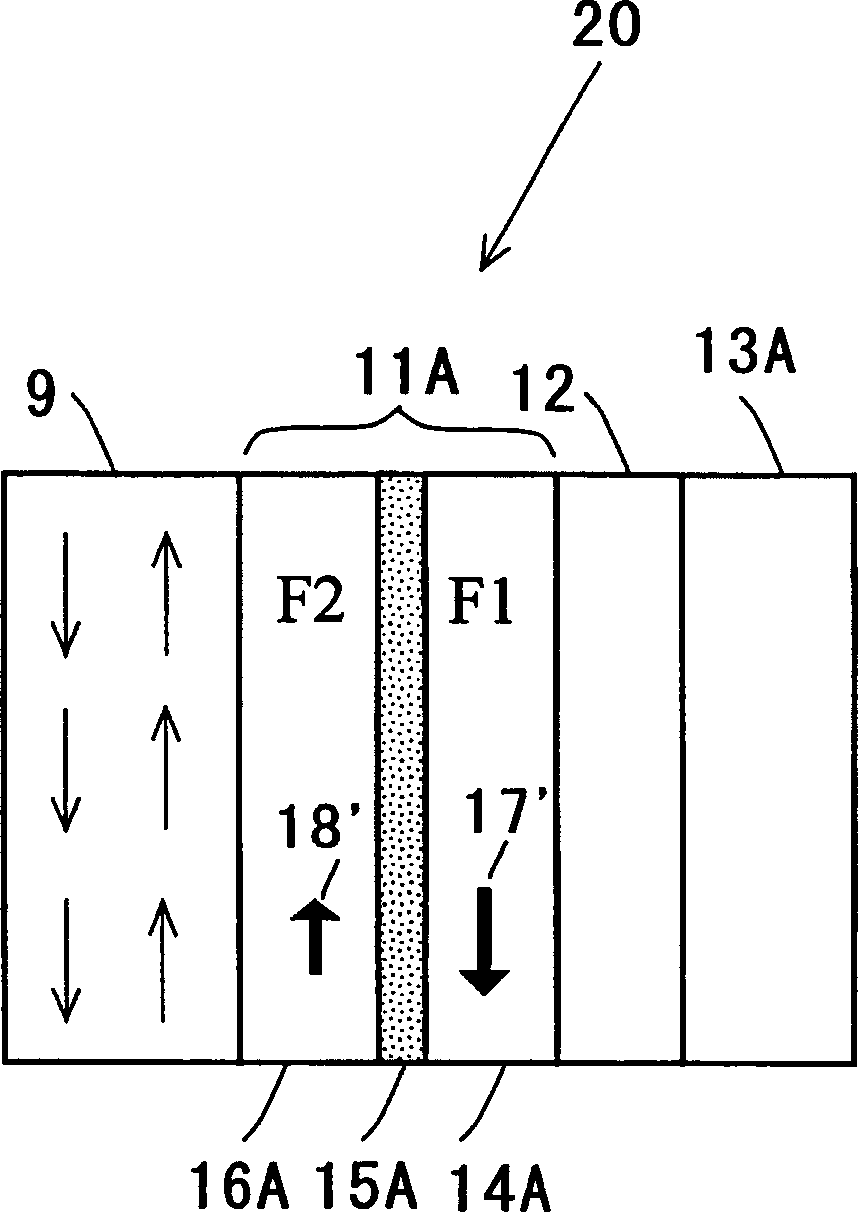

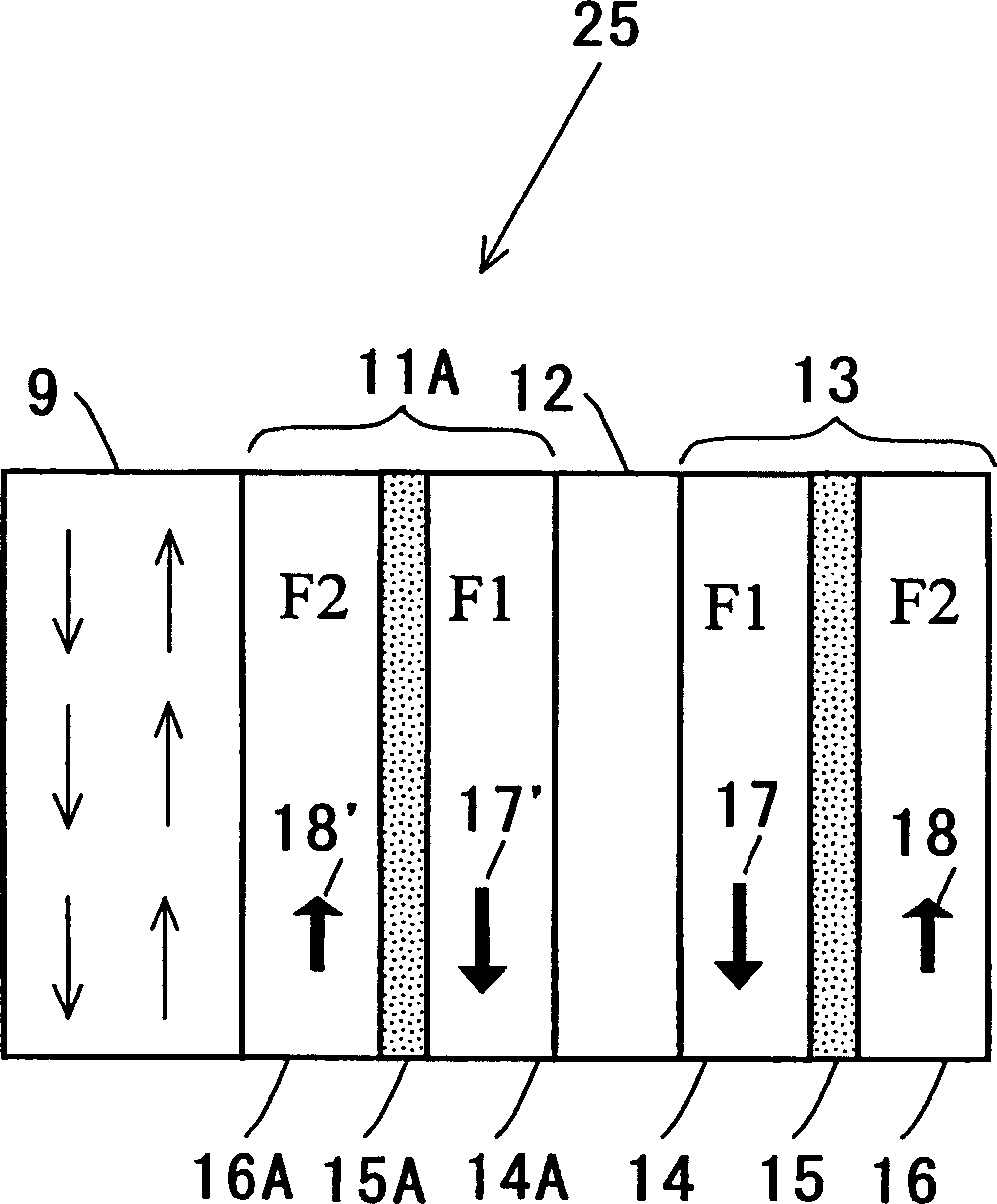

[0050] figure 1 It is a conceptual diagram of the valve-type CPP giant magnetoresistance element of the first embodiment, figure 1 (a) is the case where the magnetization of the first magnetic layer of the ferromagnetic free layer is antiparallel to the magnetization of the pinned layer, figure 1 (b) shows the case of parallelism. Such as figure 1 As shown, the CPP type giant magnetoresistive element 10 of the first embodiment is formed as follows: the antiferromagnetic layer 9, the ferromagnetic fixed layer 11, the nonmagnetic conductive layer 12 and the ferromagnetic free layer 13 have a laminated structure, and the ferromagnetic free layer The first magnetic layer 14 and the second magnetic layer 16 of 13 are magnetically antiparallel coupled through the magnetic c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com