Undercurrent type molten metal valve

A technology of molten metal and submerged flow, applied in metal processing equipment, casting melt containers, casting equipment, etc., can solve the problems of low yield, decline in product quality, and bubbles in castings, and achieve good quality and improve product quality. , to avoid the effect of suction and slag inclusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

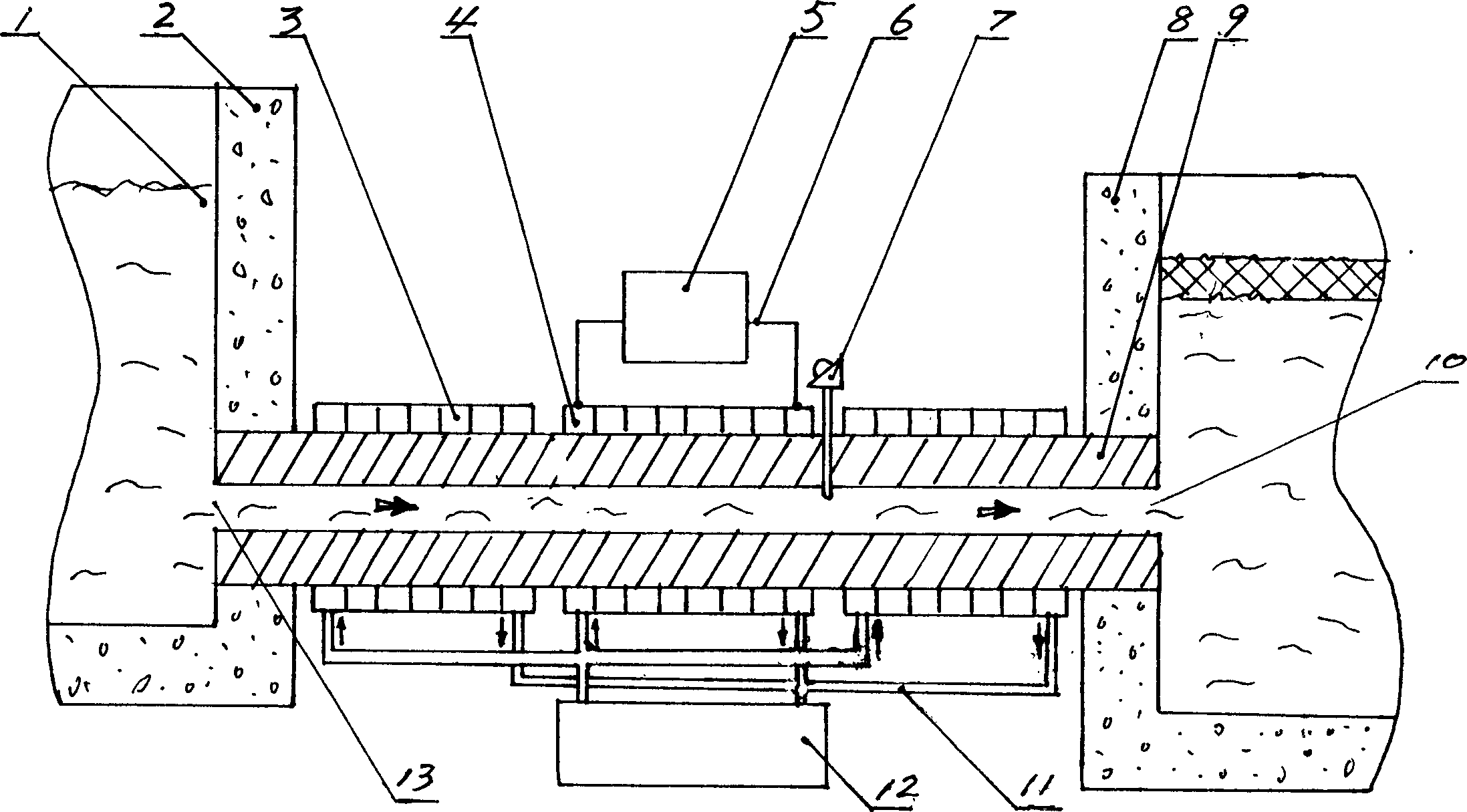

[0012] As shown in the accompanying drawings, the submerged metal liquid valve of the present invention contains a melting furnace 2 and a holding furnace 8, and the corresponding positions at the bottom of the furnace wall of the melting furnace 2 and the holding furnace 8 are respectively processed with an outlet 13 and an inlet 10. A delivery pipe 9 is indirectly arranged so that the inner cavity of the melting furnace 2 and the holding furnace 8 is communicated. Wherein the delivery pipe 9 is a silicon carbide pipe. A circulating cooling medium source 12 is arranged between the melting furnace 2 and the holding furnace 8, and the circulating cooling medium source may be circulating cooling water, circulating compressed air or other refrigerants. The refrigerant is a refrigerant for refrigerators or air conditioners. Condenser 3 is arranged on delivery pipe 9, and this condenser can be made by coiling with metal conduit, also can be metal water jacket etc. Both ends of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com