Oil sand asphalt treating method

A kind of technology of oil sand asphalt and treatment method, which is applied in the processing of tar asphalt/petroleum asphalt/natural asphalt, only multi-stage serial refining and cracking process treatment, processing tar asphalt/petroleum asphalt/natural asphalt by selective extraction, etc., It can solve the problems of high cost and high processing cost, and achieve the effect of low equipment cost, low operating cost and high investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This example is used to illustrate the oil sand bitumen treatment method provided by the present invention.

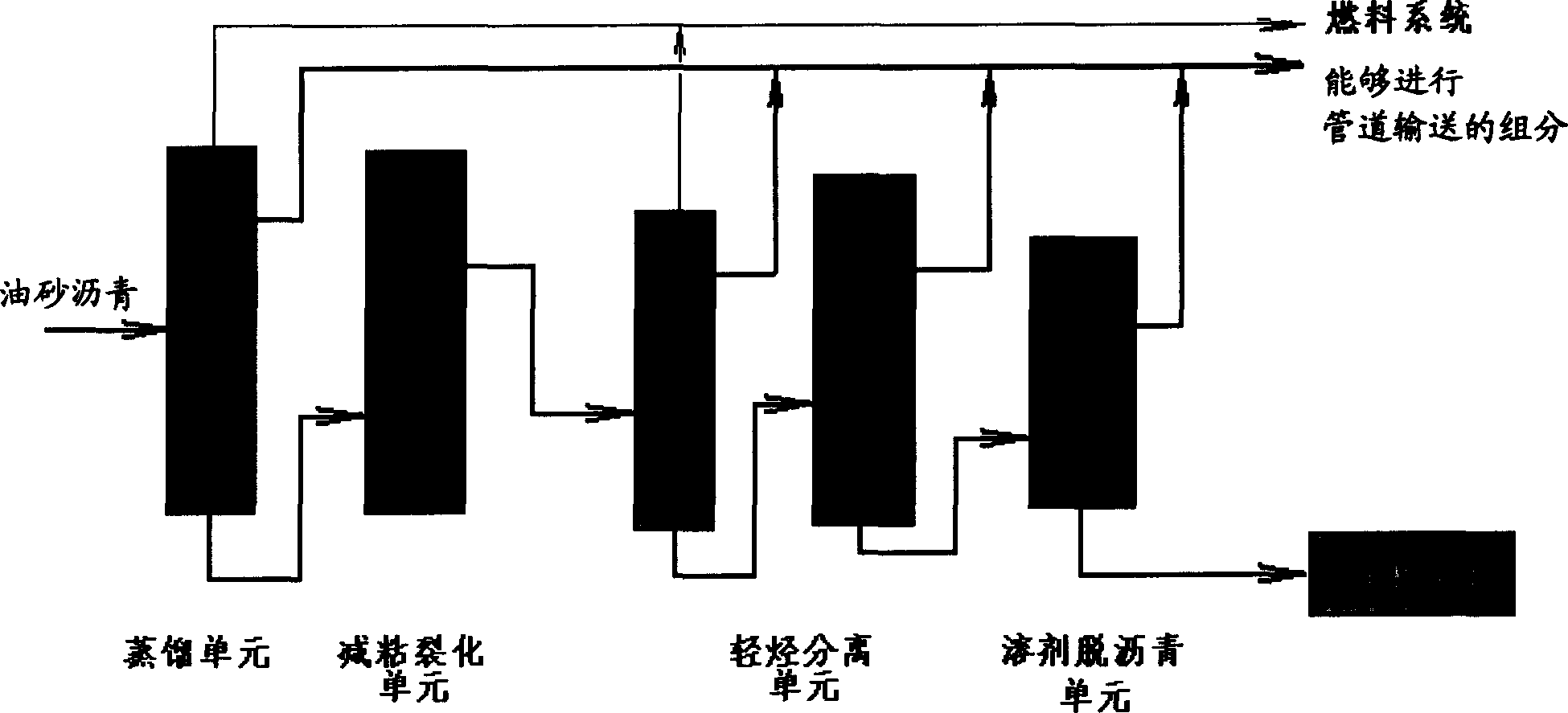

[0037] according to figure 1 In the process shown, the oil sand bitumen is fed to the distillation unit, so that the components in the oil sand bitumen with a boiling point lower than 200 ° C can be directly separated from the oil sand bitumen as components that can be transported by pipeline, and the remaining high boiling point The distillation residue oil enters the visbreaking unit for visbreaking. The visbreaking conditions are temperature of 400°C, pressure of 0.5 MPa, and residence time of 2 hours. The visbroken product enters the light hydrocarbon separation unit for separation , the components with a boiling point lower than 500°C are separated as components that can be transported in pipelines, and the remaining high-boiling heavy components are used as raw materials for solvent deasphalting, using n-butane solvent for contact extraction in the solvent...

Embodiment 2

[0039] This example is used to illustrate the oil sand bitumen treatment method provided by the present invention.

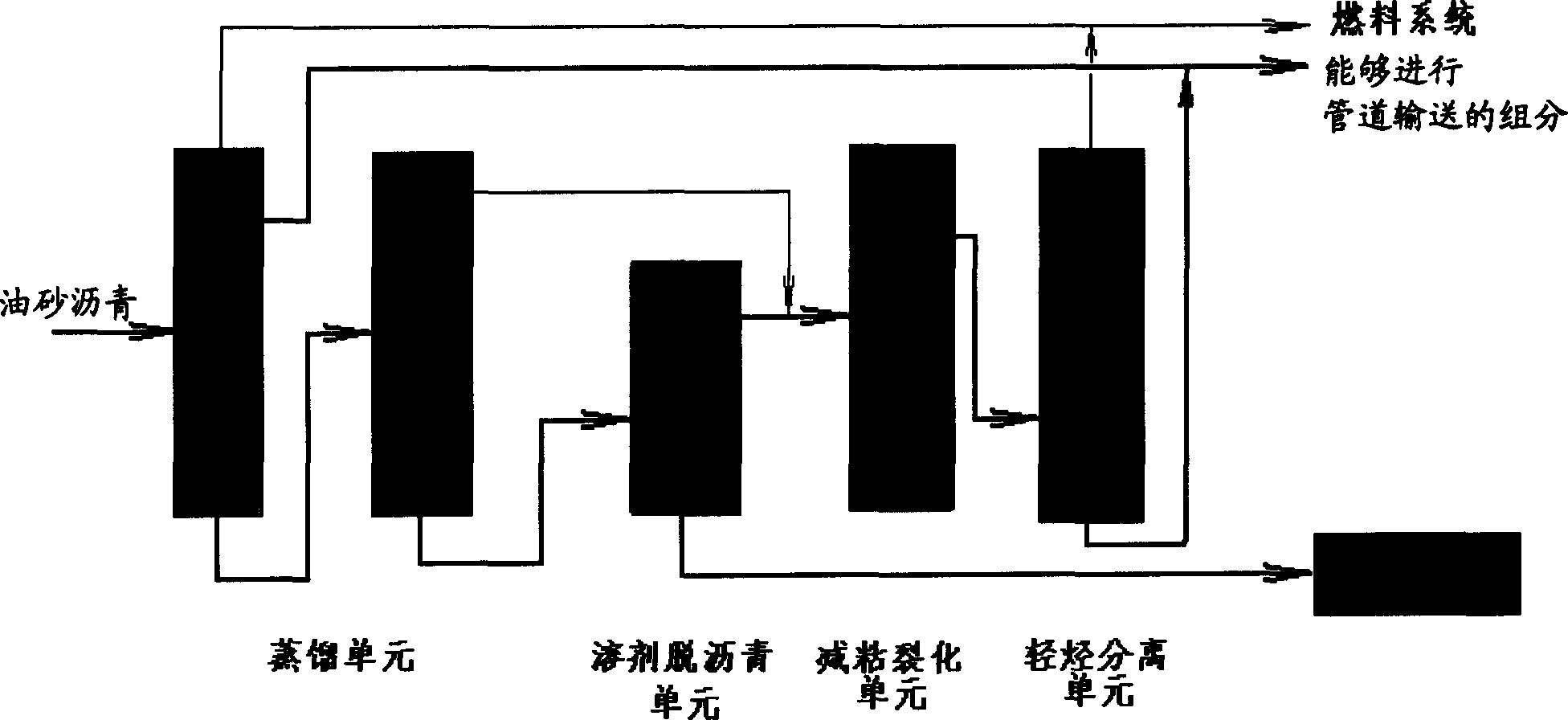

[0040] according to figure 2The process shown feeds the oil sands bitumen to an atmospheric distillation unit to separate the overhead components of the oil sands bitumen with a boiling point below 200°C directly from the oil sands bitumen as components that can be transported by pipeline , then feed the atmospheric residue at the bottom of the tower to the vacuum distillation unit, separate the vacuum overhead oil with a boiling point of 200-500°C and the vacuum residue with a boiling point greater than 500°C, and combine the vacuum residue with The pentane mixed solvent is subjected to contact extraction in the solvent deasphalting unit. The conditions for solvent deasphalting are that the temperature at the bottom of the tower is 150°C, the temperature at the top of the tower is 170°C, the pressure is 5 MPa, and the solvent ratio is 4:1. After deasphalting,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com