Organic electroluminescent devices and metal complex compounds

An electroluminescence device and metal complex technology, which can be applied in electroluminescence light sources, organic chemistry, electric light sources, etc., and can solve the problems of not being able to achieve persistence and luminescence characteristics at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

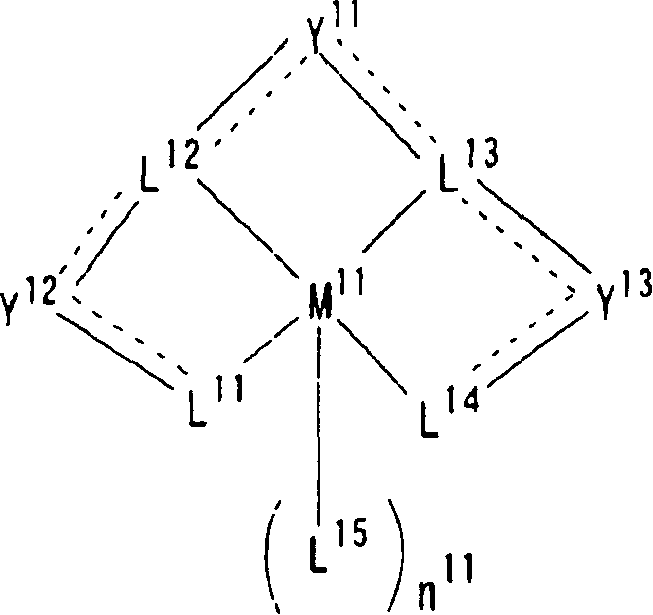

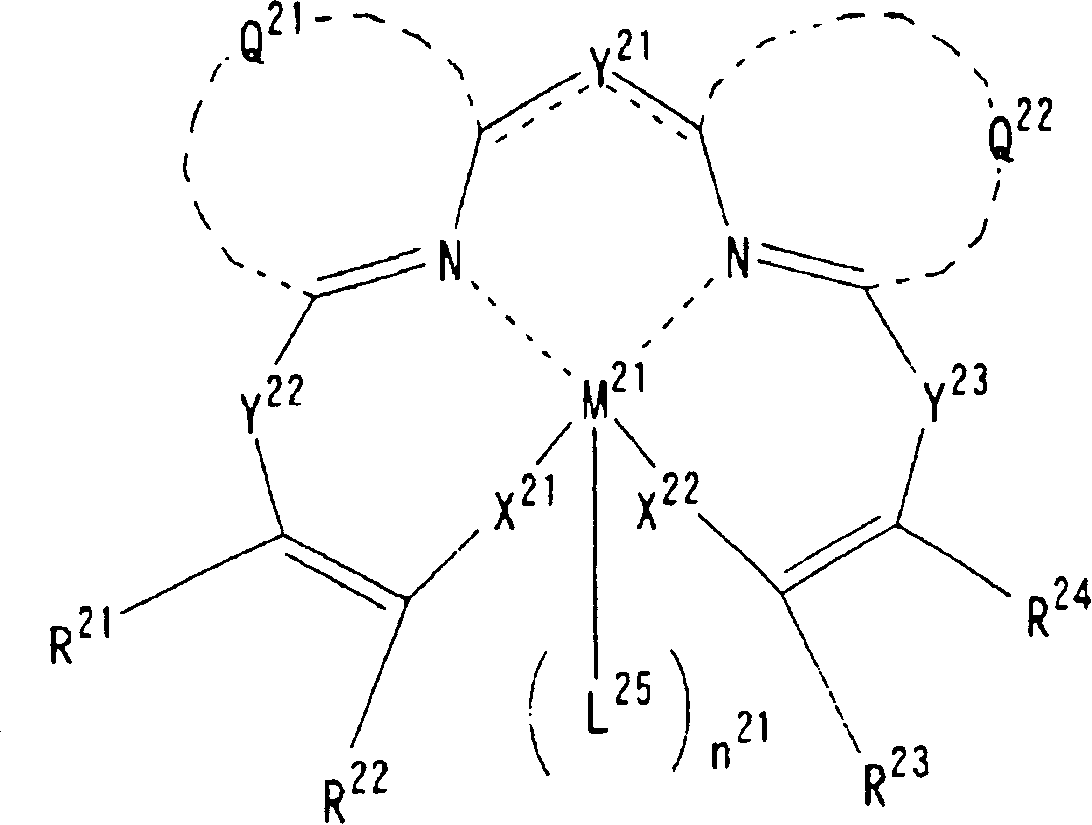

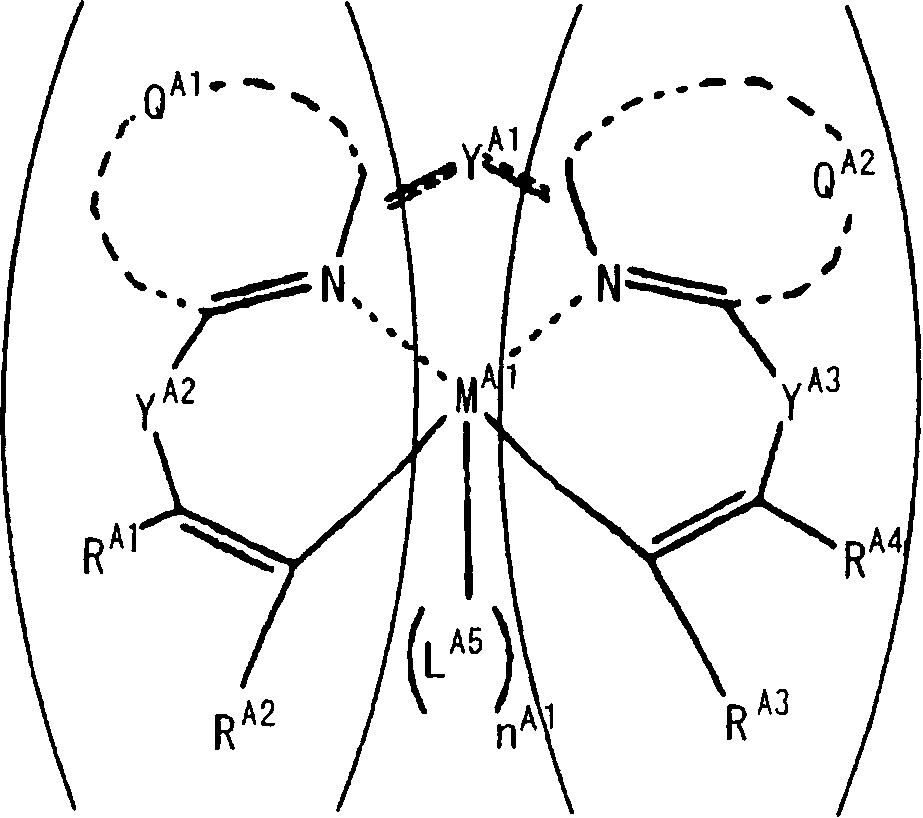

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0491] The present invention will now be explained in more detail with reference to the following examples, but it should be understood that the specific scheme for implementing the present invention does not constitute a limitation of the present invention.

[0492] Synthesis of compound (1)

[0493] To 6,6'-bis(2-hydroxyphenyl)-2,2'-bipyridine (0.1g) and PtCl 2 Benzonitrile (10 ml) was added to (0.16 g), followed by heating to reflux for 3 hours under a nitrogen atmosphere. After cooling the reaction solution to room temperature, methanol was added to the reaction solution to form a precipitate, which was suction filtered. The obtained solid was purified by silica gel chromatography (chloroform as a developer) to obtain 0.06 g of compound (1). The structure of compound (1) was identified by mass spectrometry. Under nitrogen atmosphere, UV irradiates the chloroform solution containing compound (1) to obtain red-orange emission light (λ max = 624nm).

[0494]

[0495] ...

Embodiment 1

[0514]The cleaned ITO substrate is placed in a vacuum evaporator, and evaporated TPD (N, N-diphenyl-N, N-two (m-tolyl) benzidine) forms a film with a thickness of 50 nm on the substrate, Compound (1) according to the present invention and compound A (weight ratio 1:17) were then co-evaporated to form a film having a thickness of 36 nm, followed by evaporation of compound B to form a film having a thickness of 36 nm. Next, a pattern mask (adjusting each emission region to 4 mm × 5 mm) was set on the organic thin layer obtained above, and lithium fluoride was further evaporated in a vacuum evaporator, thereby forming a film having a thickness of 3 nm thereon. ; Then deposit a 400nm thick aluminum film.

[0515] The EL device thus produced was made to emit light by means of a source-measurement device (Model 2400 (trade name)) manufactured by Toyo Technica Co., Ltd. by applying a DC constant voltage thereto; and using a photometer manufactured by Topcon Co. BM-8 (trade name) mea...

Embodiment 2

[0517] Place the cleaned ITO substrate in a vacuum evaporator, and evaporate TPD (N, N-diphenyl-N, N-two (m-tolyl) benzidine) successively to form a film with a thickness of 50 nm on the substrate. , and then co-evaporated compound (1) according to the present invention and compound A (weight ratio 1:2) to form a film with a thickness of 36 nm, followed by evaporation of compound B to form a film with a thickness of 36 nm. Next, a pattern mask (adjusting each emission region to 4 mm × 5 mm) was set on the organic thin layer obtained above, and lithium fluoride was further evaporated in a vacuum evaporator, thereby forming a film having a thickness of 3 nm thereon. ; Then deposit a 400nm thick aluminum film.

[0518] The EL device thus produced was made to emit light by means of a source-measurement device (Model 2400 (trade name)) manufactured by Toyo Technica Co., Ltd. by applying a DC constant voltage thereto; and using a photometer manufactured by Topcon Co. BM-8 (trade na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Maximum brightness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com