Real-time in-line testing of semiconductor wafers

A semiconductor and wafer technology, applied in the field of real-time online testing, which can solve problems such as limited applicability and continuous motion of the substrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

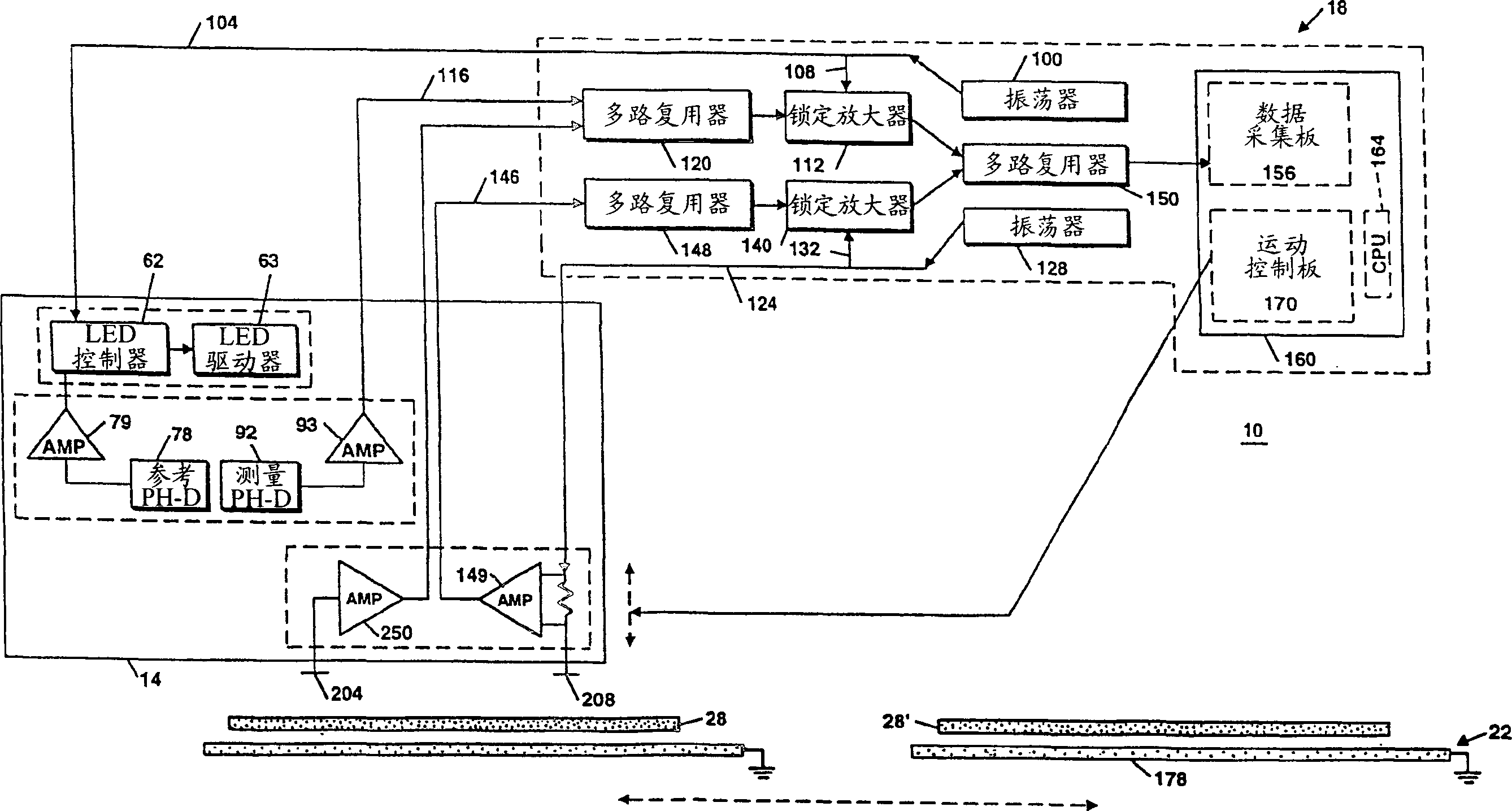

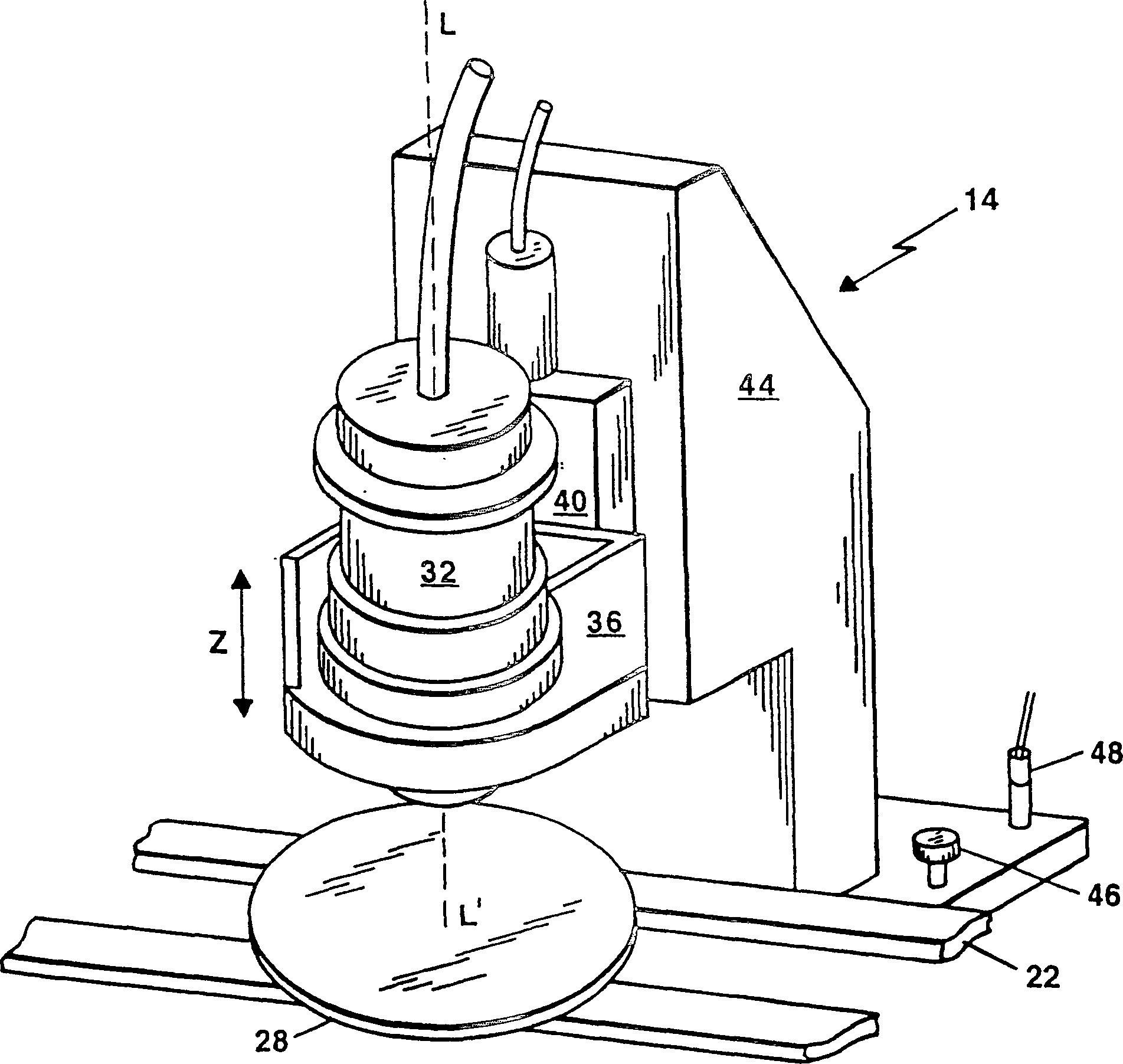

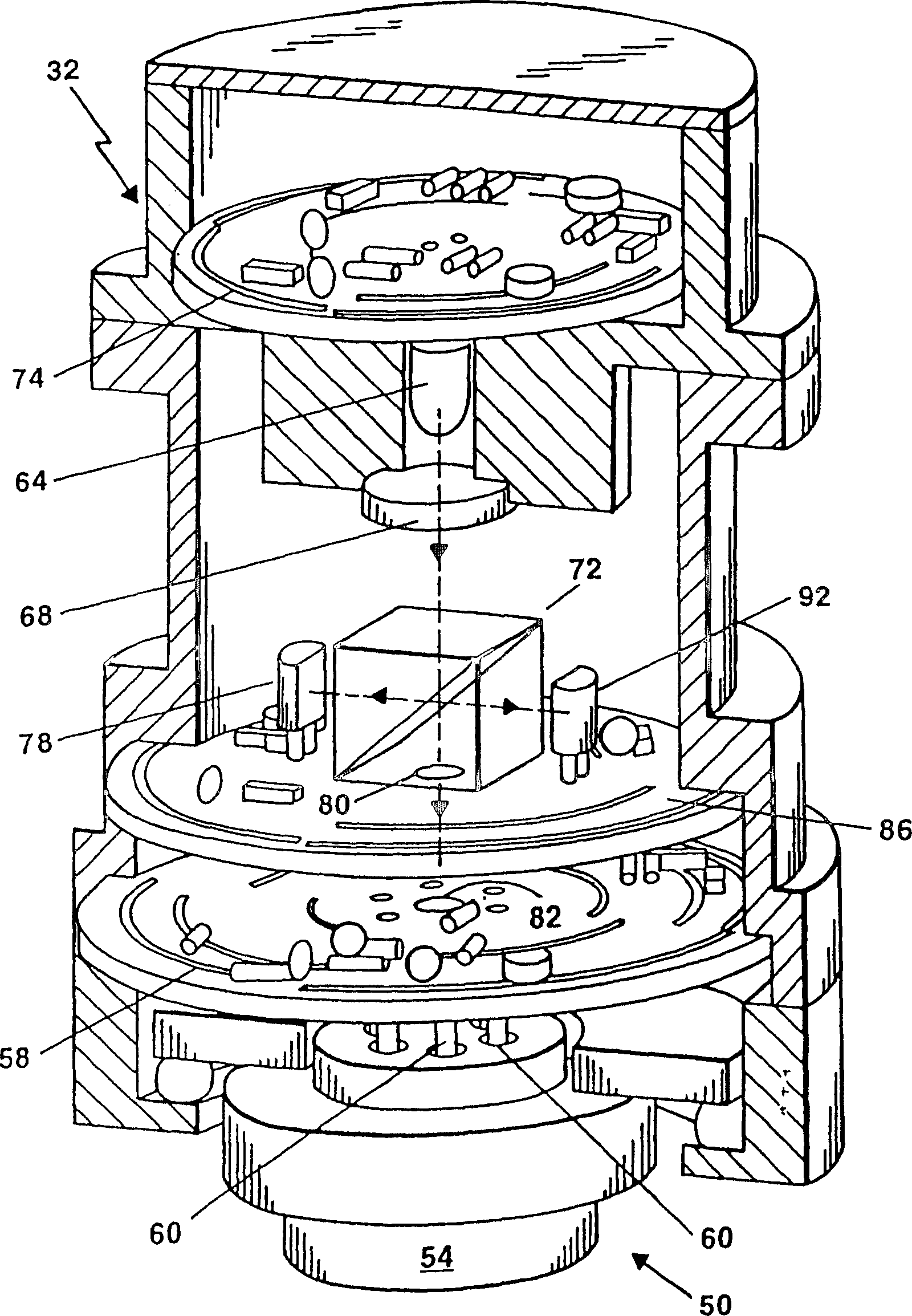

[0020] In one embodiment, the means for performing various electrical characterizations utilize the method disclosed in US Patent No. 4,544,887 for measuring the light-induced voltage at the surface of a semiconductor material, referred to as surface photovoltage (SPV). In this method, a beam of light is directed at a surface region of a sample of semiconductor material, and the light-induced change in electrical potential at the surface is measured. The wavelength of the illuminating beam is selected to be shorter than the wavelength of light corresponding to the energy gap of the semiconductor material under test. The intensity of the light beam is adjusted, the light intensity and the modulation frequency are selected, so that the AC component of the generated induced photovoltage is directly proportional to the light intensity and inversely proportional to the modulation frequency.

[0021] When measurements are made under these conditions, the AC component of the surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com