Energy storing vibration absorber of clutch and method for preventing it from hydraulic leakage

A shock absorber and clutch technology, which is applied in the direction of shock absorbers, clutches, springs/shock absorbers, etc., can solve problems such as clutch hydraulic leakage, poor shift quality, damage to clutches and brake bands, etc., to reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

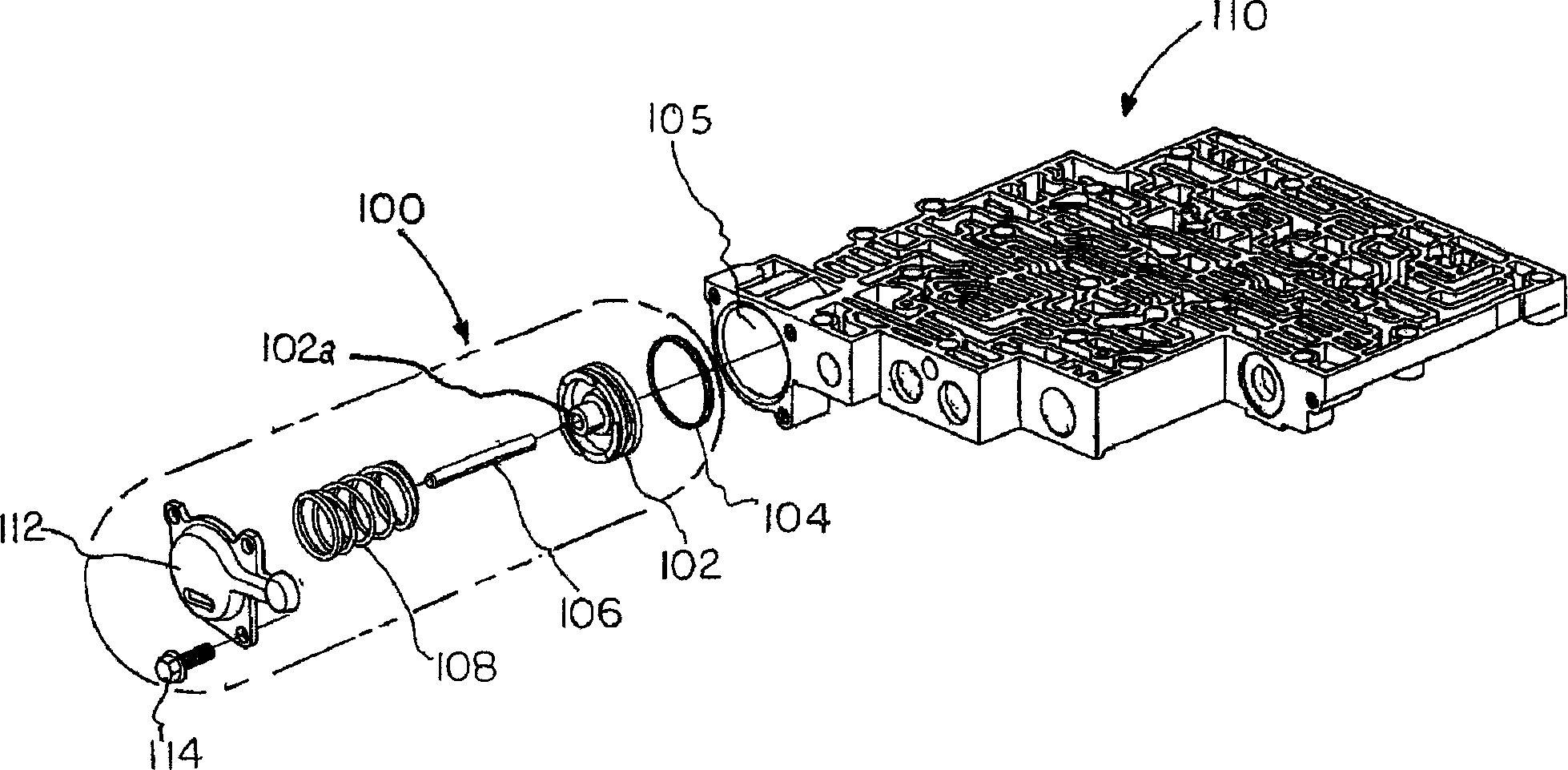

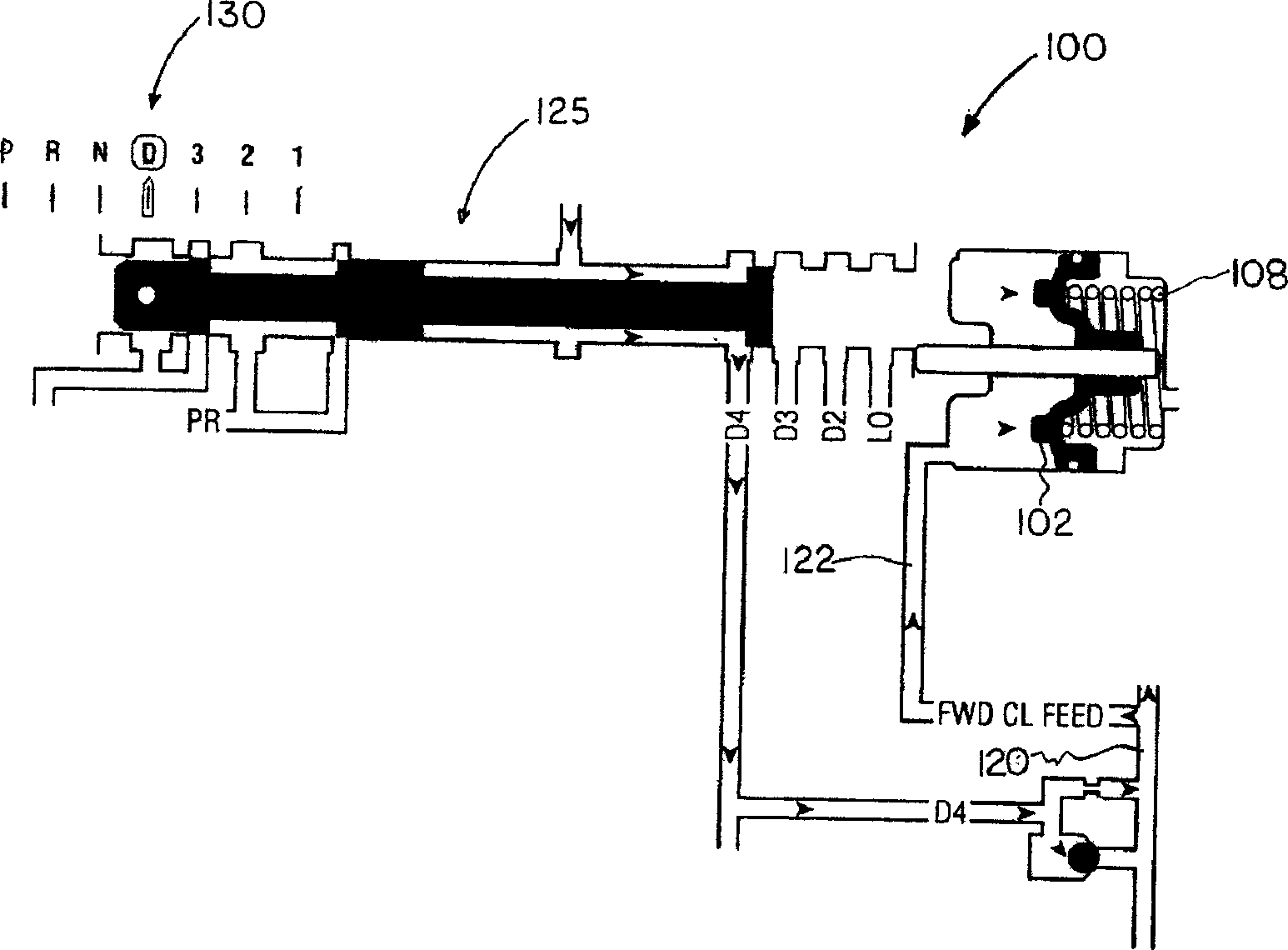

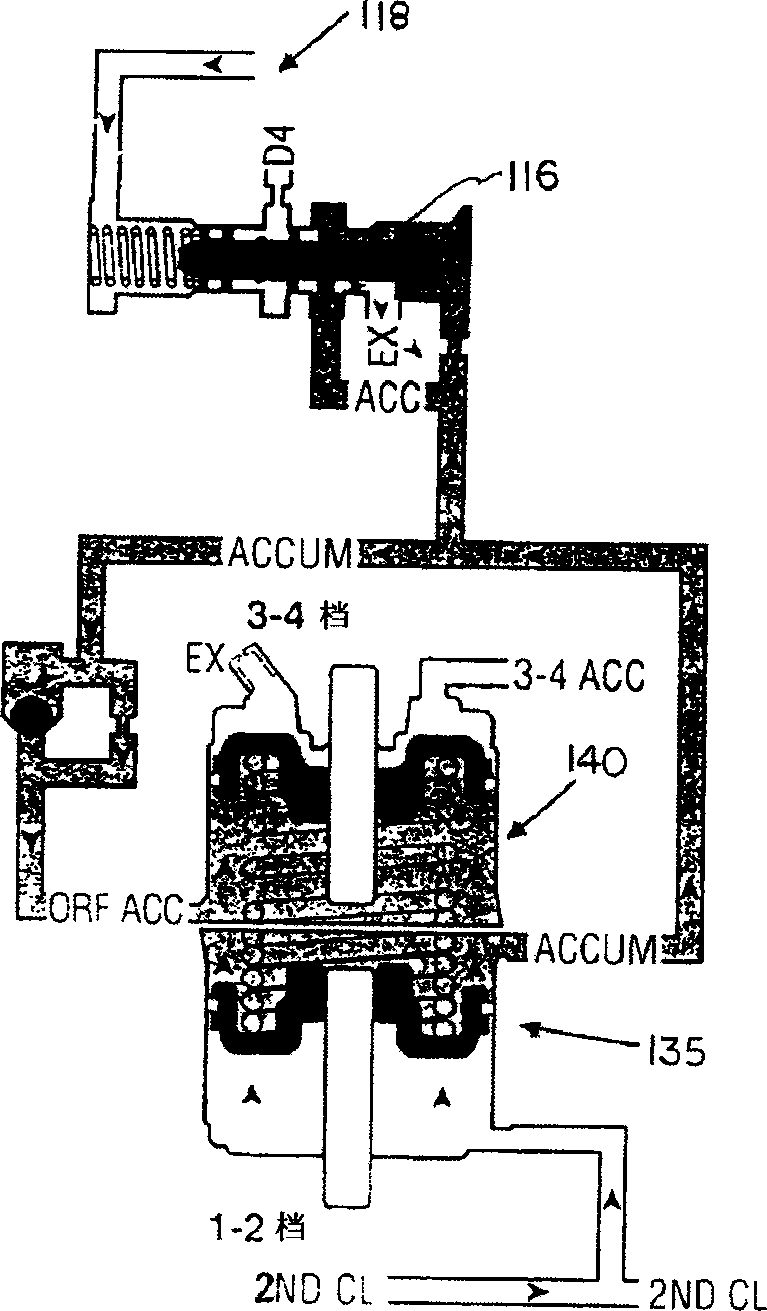

[0038] Figure 5A A pinless energy storage shock absorber piston 10 consistent with the present invention is shown. It can be seen that the improved structure of the piston 10 of the current energy storage shock absorber eliminates the OEM pins 106, 147, hole 102a, and the corresponding pin / piston interface. This is precisely the hydraulic leakage of the clutch in the design of the OEM energy storage shock absorber. The main root cause. Because the pin 106 in the OEM forward clutch energy storage shock absorber 100 and the pin 147 in the 1-2 and 3-4 gear energy storage shock absorbers have been deleted in the current energy storage shock absorber assembly, so The central hole 102a in the OEM piston 102 is also omitted from the current piston structure, providing a radial solid web structure at 12b in the current design.

[0039] This design change of the present invention is accomplished by the energy storage shock absorber piston 10. The energy storage shock absorber piston 10 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com