Container checking system with CT fault scanning function

A tomographic scanning and inspection system technology, applied in the direction of measuring devices, nuclear radiation exploration, instruments, etc., can solve the problems of restricting the accuracy of complex container cargo inspection and the inability to obtain tomographic images, so as to achieve reasonable design, accurate inspection results, The effect of reducing the footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

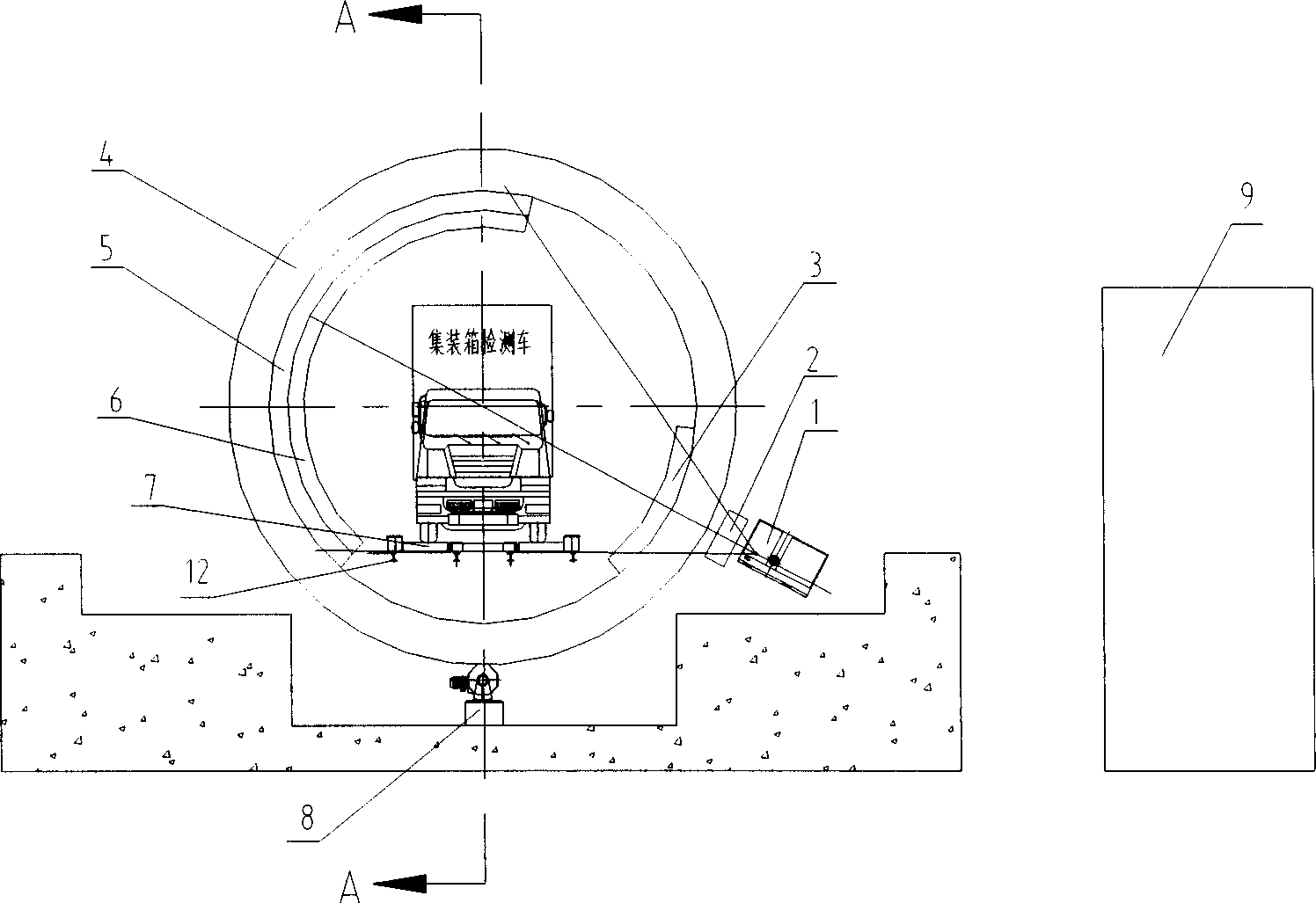

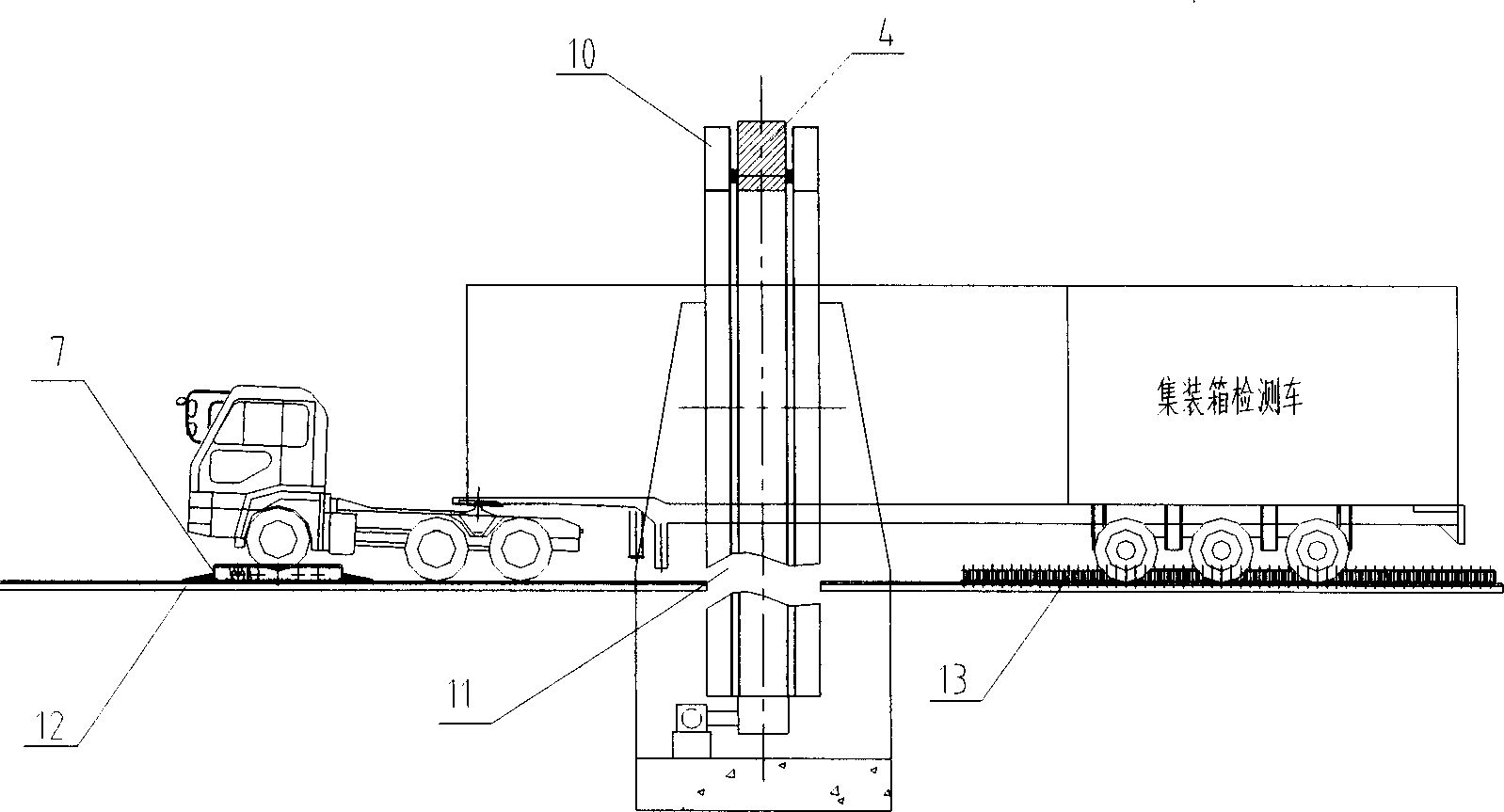

[0014] see figure 1 and figure 2 , the present invention includes a radiation source 1 using a linear electron accelerator or an isotope, a corrector 2, a front collimator 3, a rear collimator 6, a detector array 5 and a rail 12 placed in the scanning area, placed on the rail 12 The trailer 7, the side guide device 13 with a double-sided vertical roller structure placed on the rail 12, and the remote control device 9 equipped with an image acquisition module, an operation inspection module, and an electrical control module. The rail 12 placed in the scanning area is composed of two sections and forms a discontinuous structure, and an annular rotating frame 4 that allows the container inspection vehicle to pass is arranged in the longitudinal direction of the discontinuous gap 11 . The outer side of the circular rotating frame 4 fixes the radiation source 1 and the corrector 2 facing the radiation source 1, and the inner side of the circular rotating frame 4 fixes the front c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com