Substrate mounting table, substrate processing apparatus and substrate temperature control method

A temperature control method and substrate processing device technology, applied in the direction of computer control, electrical program control, general control system, etc., can solve the problem of reduced temperature controllability, difficulty in ensuring responsiveness and uniformity of temperature control of the substrate to be processed, difficulty in He gas Uniform diffusion and other issues to achieve good temperature control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

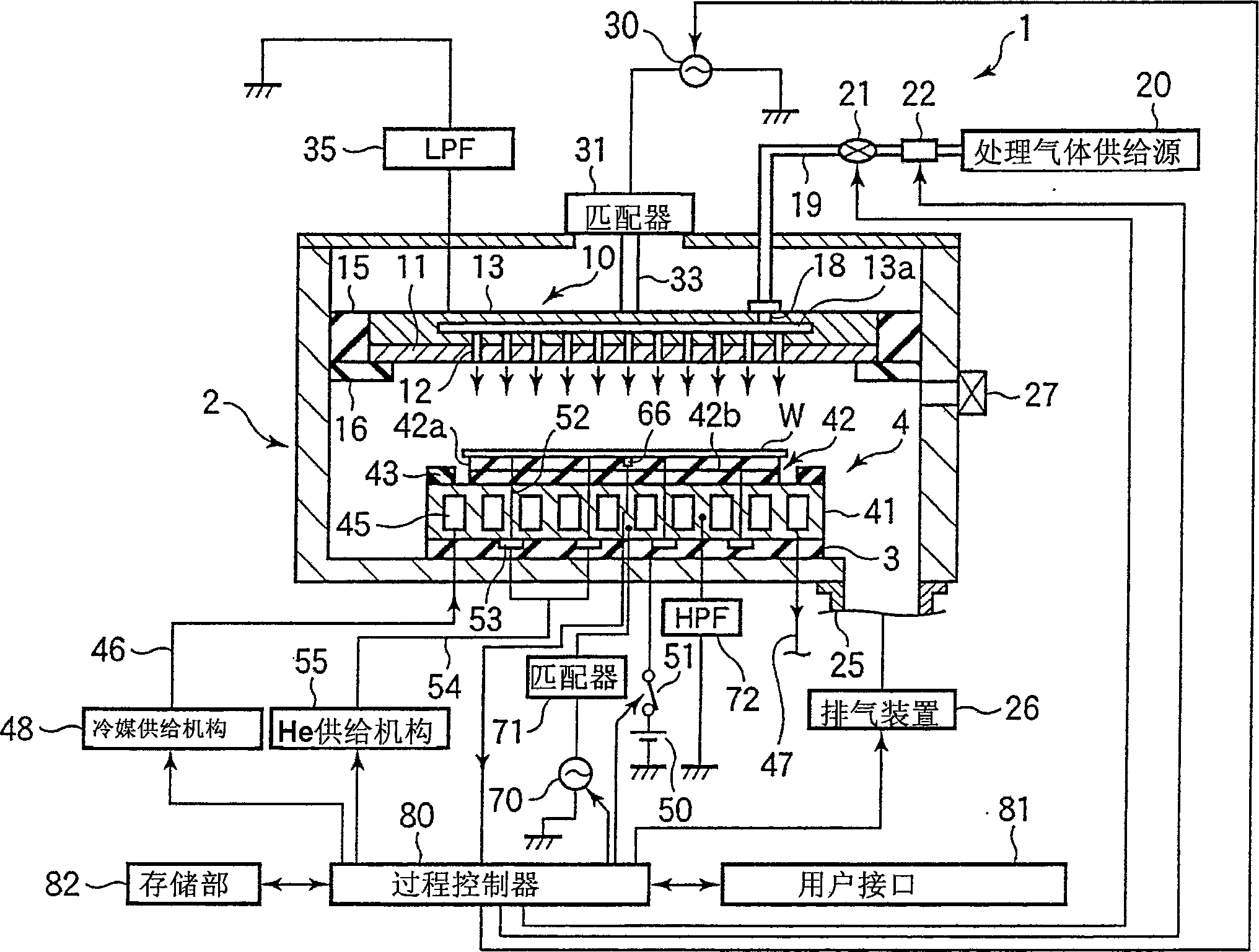

[0071] Next, an embodiment of the present invention will be described with reference to the drawings.

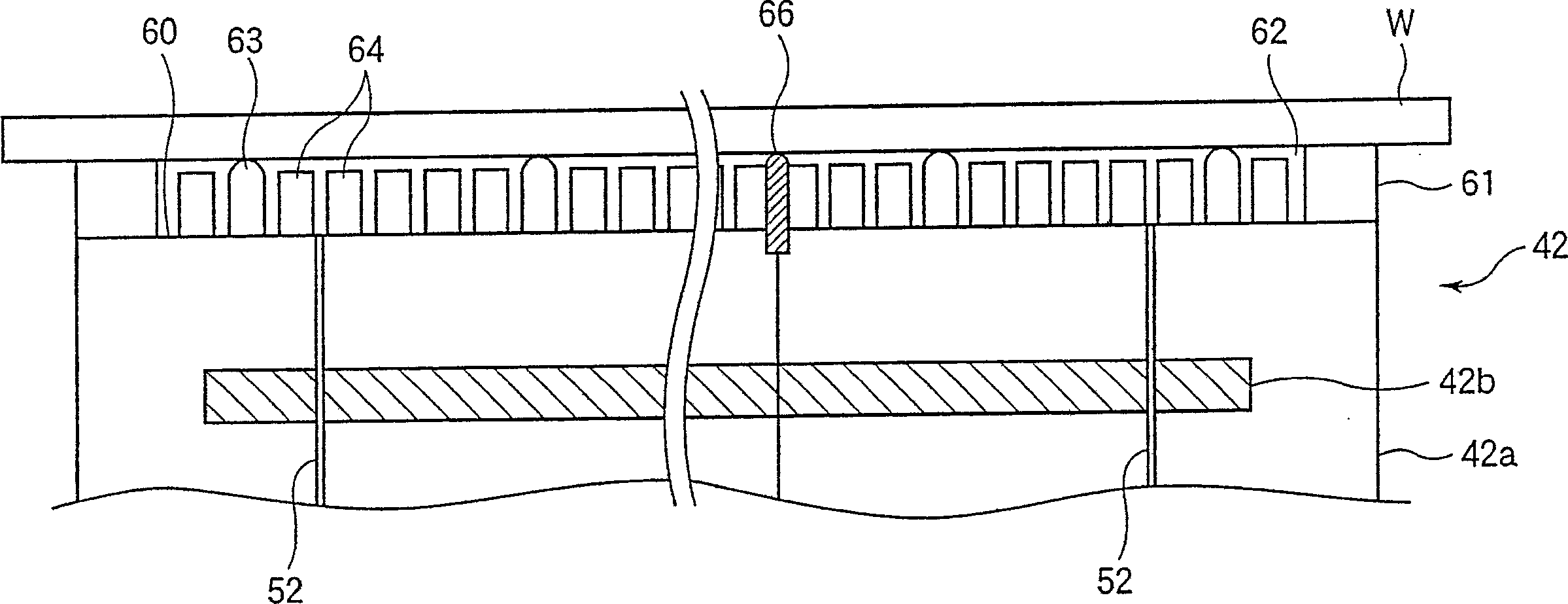

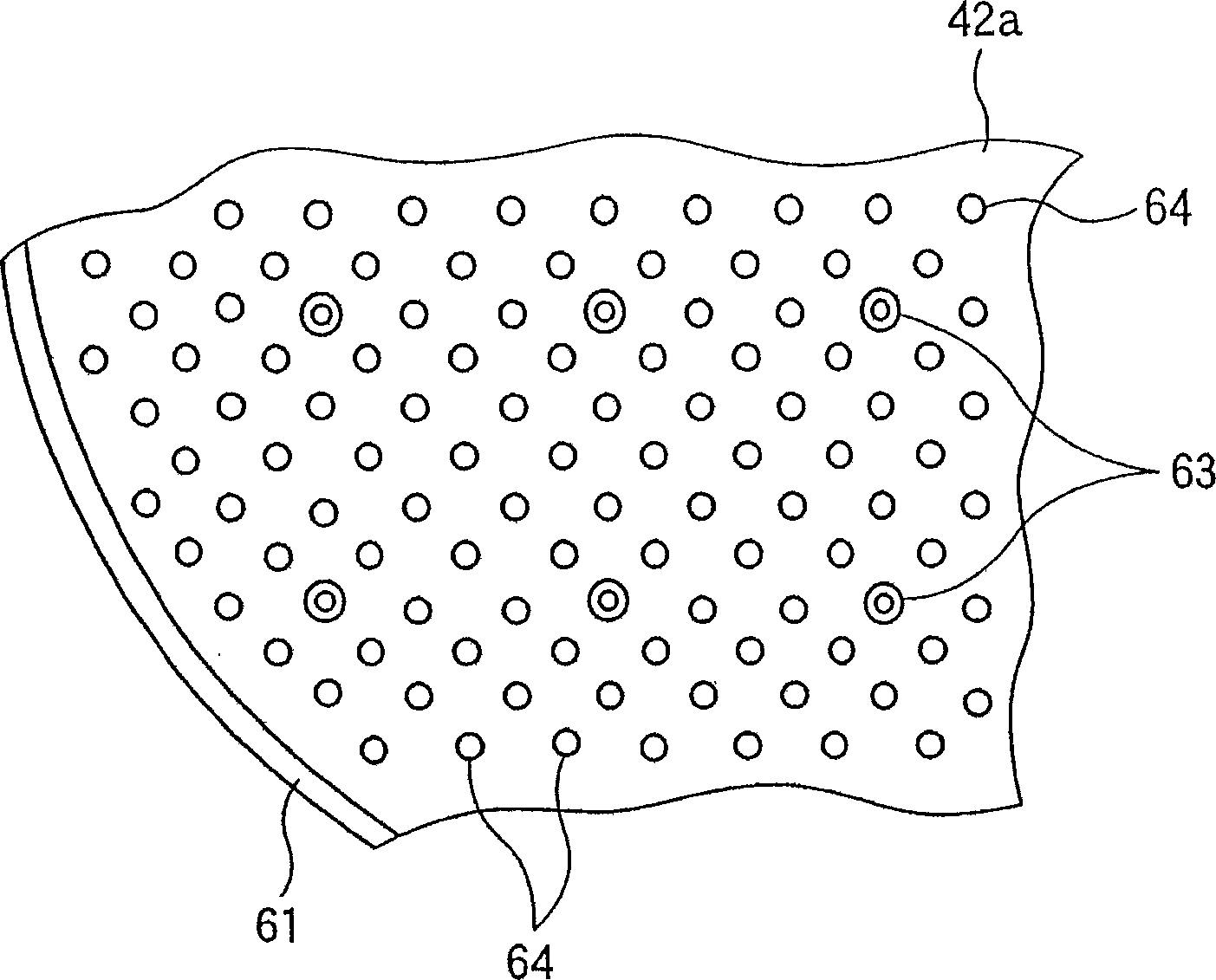

[0072] Here, an example in which the substrate mounting table of the present invention is applied to a plasma processing apparatus will be described. figure 1 It is a cross-sectional view showing a plasma processing apparatus provided with a wafer stage according to an embodiment of the present invention, figure 2 It is an enlarged cross-sectional view showing a main part of a wafer stage according to an embodiment of the present invention.

[0073] The plasma processing apparatus 1 is configured as a parallel plate etching apparatus in which electrode plates face up and down in parallel, and capacitively coupled plasma is formed by a high-frequency electric field formed between them.

[0074] This etching processing apparatus 1 has a chamber 2 which is made of, for example, aluminum whose surface is anodized, and which is formed in a cylindrical shape. At the bottom of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com