Wall surface decoration plate and its producing method

A technology for wall decoration and composite boards, which is applied in the field of building decoration materials, can solve the problems of heavy weight of decorative boards, affect the construction period, and high material costs, and achieve the effects of low construction cost, convenient operation, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

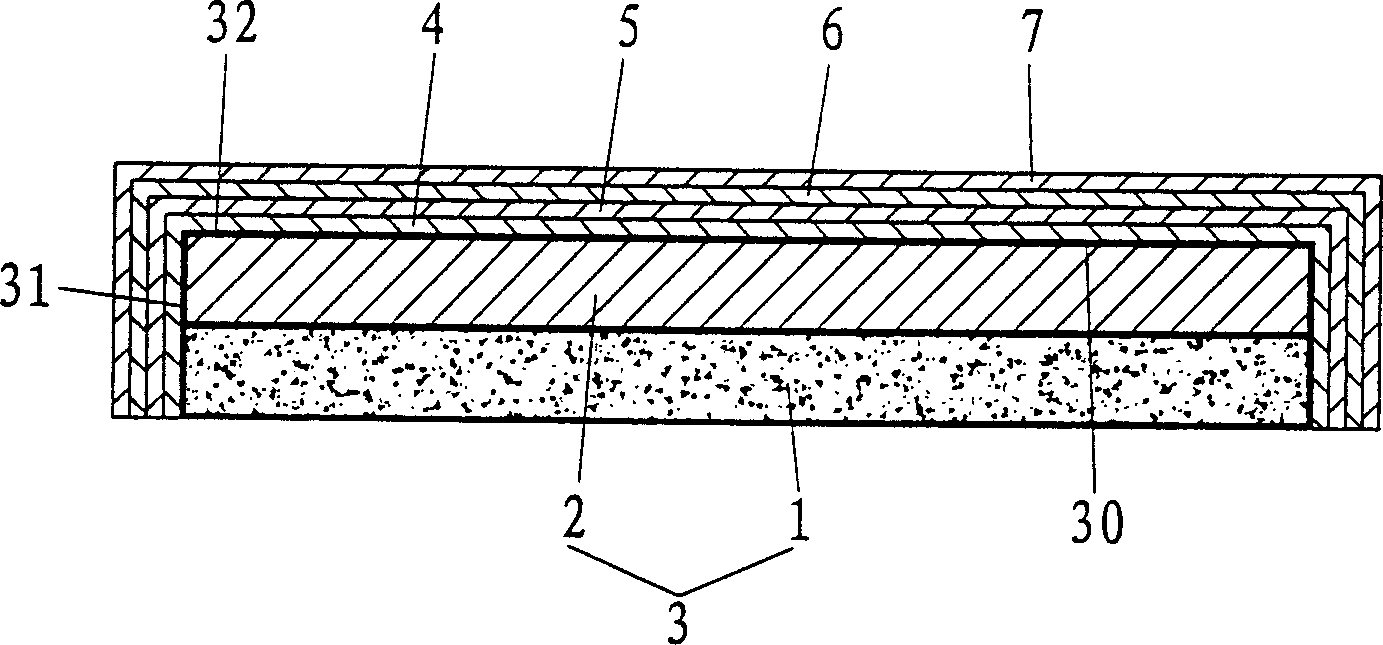

[0030] Such as figure 1 , 2 As shown, the wall decoration panel of the present invention is a polystyrene foam board 1 made by extrusion. Asbestos cement board 2 forms composite board 3, the thickness of this composite board 3 is 25-100mm, light in weight (2 ), protect and fix with adhesive 30 up and down and around the composite board 3; after drying for 12-24 hours at normal temperature, scrape the high-viscosity anti-cracking putty layer 4 on the periphery 31 and the surface 32 of the composite board 3 After polishing and smoothing, dry under natural conditions so that its moisture content is less than or equal to 8%; then spray the sealing primer layer 5, intermediate paint layer 6 and topcoat layer 7 on the surroundings 31 and surface 32 of the composite board 3 .

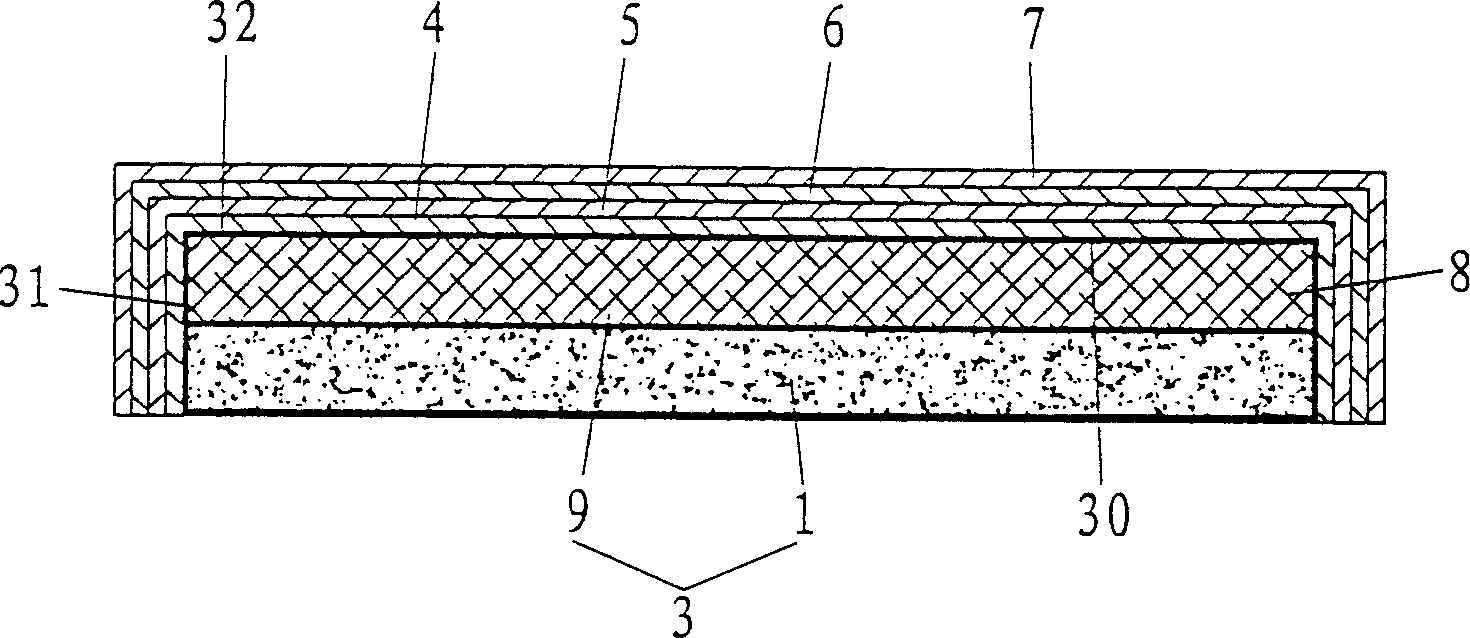

[0031] Such as image 3 As shown, the wall decoration board can also be coated with a plastering glue 9 embedded in an alkali-resistant glass fiber mesh 8 on the polystyrene foam board 1 to form a composite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com