Conveying device

A technology for conveying devices and conveying paths, which is applied in the direction of conveyor control devices, conveyors, transmission devices, etc., can solve problems such as uneven rotation, low precision of transmission distance, and overall enlargement of the device, achieving excellent durability, Improved wear resistance and high-precision movement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

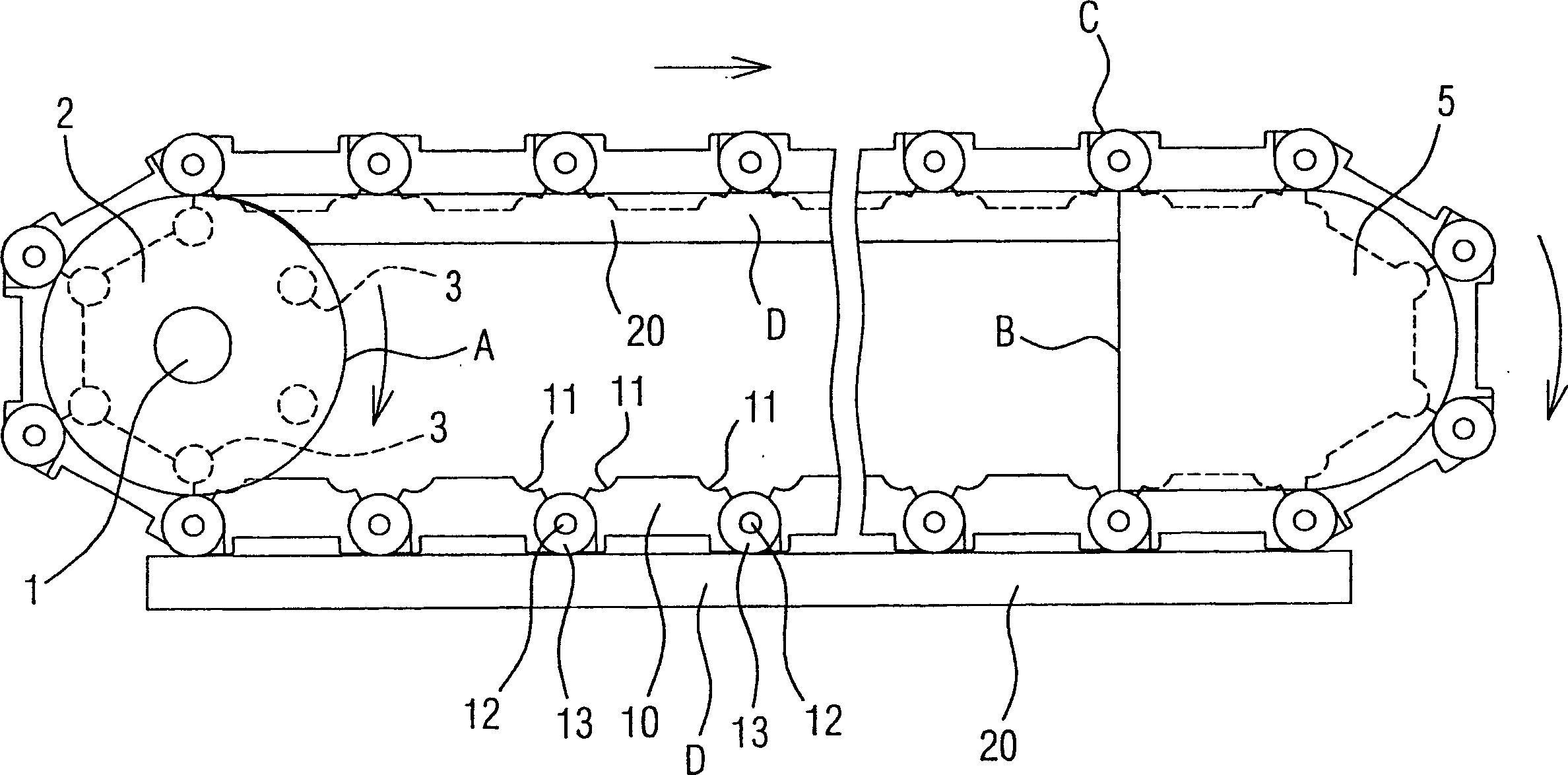

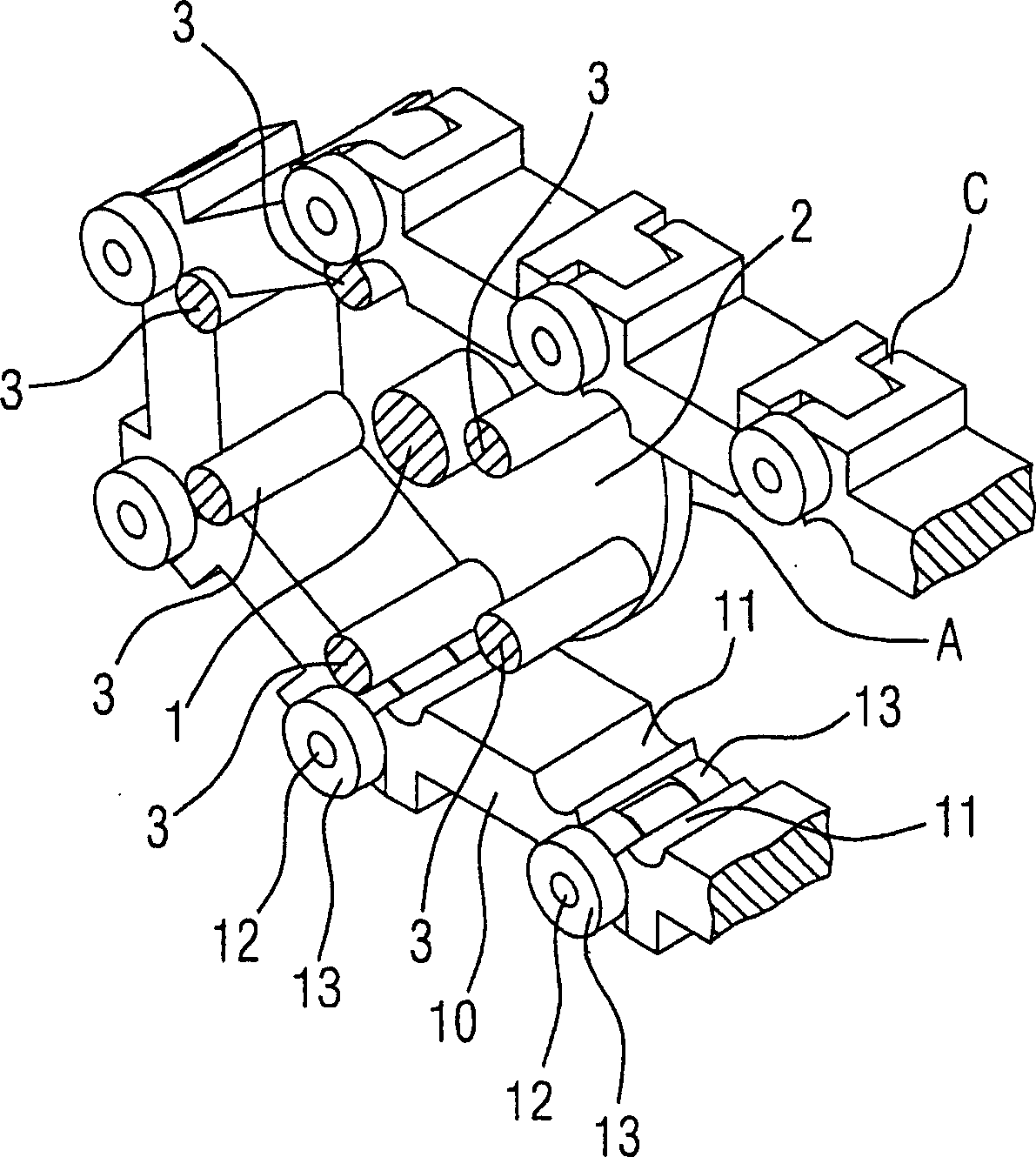

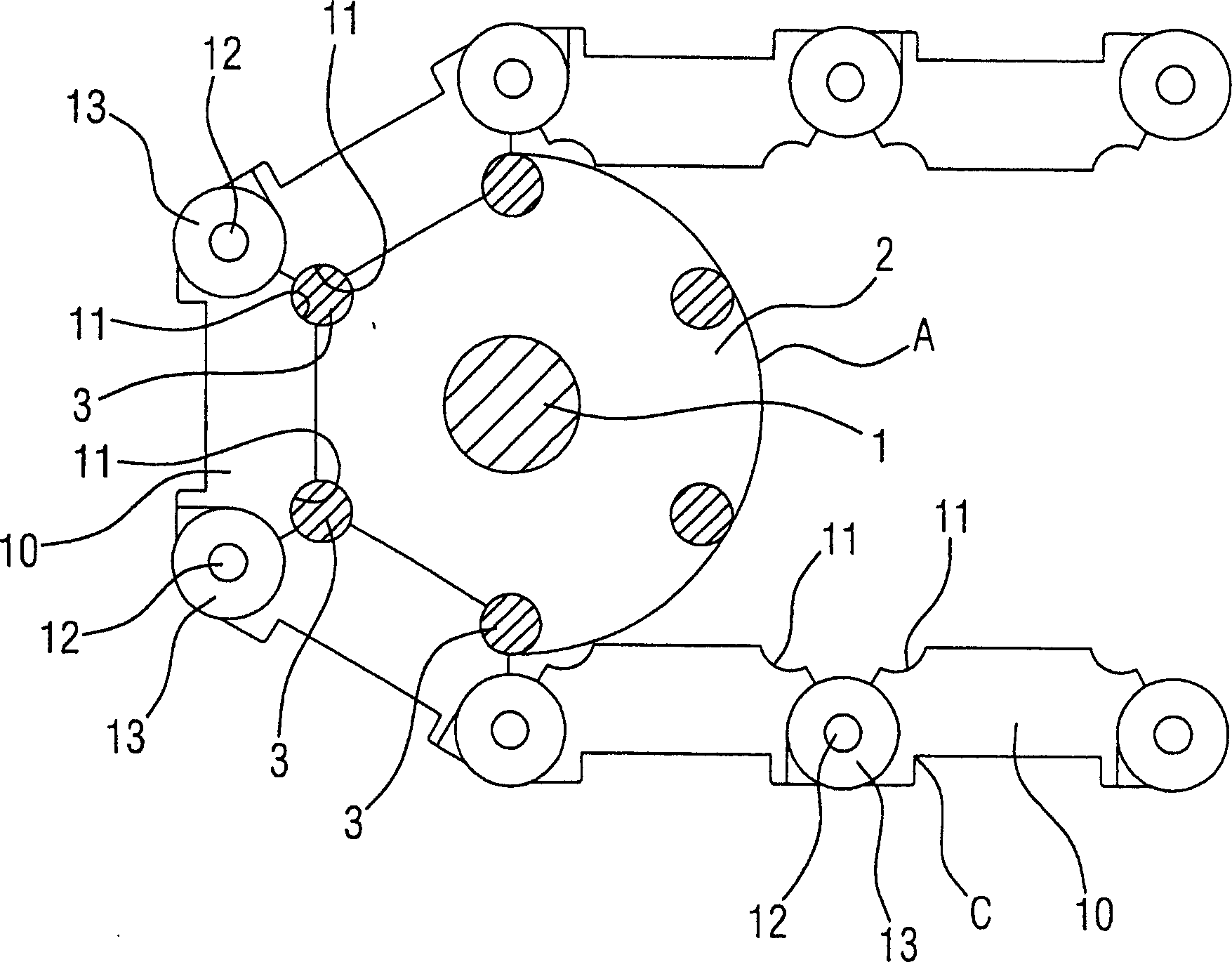

[0053] The present invention mainly provides a conveying device capable of precise linear conveying without backlash, for example, using figure 1 The illustrated embodiment embodies the conveying device, which is characterized in that it includes: a sprocket A rotated by a drive unit; a guide body B arranged on a desired conveying path; The chain C on the top; the walking guide rail D, which is arranged on the conveying path connecting the sprocket A and the guide body B in order to guide the chain C; and the rail guide unit, which connects the walking guide rail D and the chain C, so that the chain C can Move along the walking guide rail D.

[0054] In addition, the above-mentioned sprocket A has: a pair of rotating base plates 2 arranged at a predetermined interval; ;

[0055] The guide body B has a pair of guide substrates 5 arranged at a predetermined interval;

[0056] The above-mentioned chain C has: a plurality of connecting rods 10; connecting pins 12, connecting t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com