Virtual coordinate measurer based on data image treating and its measuring method

A technology of virtual coordinates and data images, applied in the field of machinery, can solve the problems of low cost, high price, and high cost, and achieve the effect of reducing construction cost, low-cost measurement, and simplifying the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

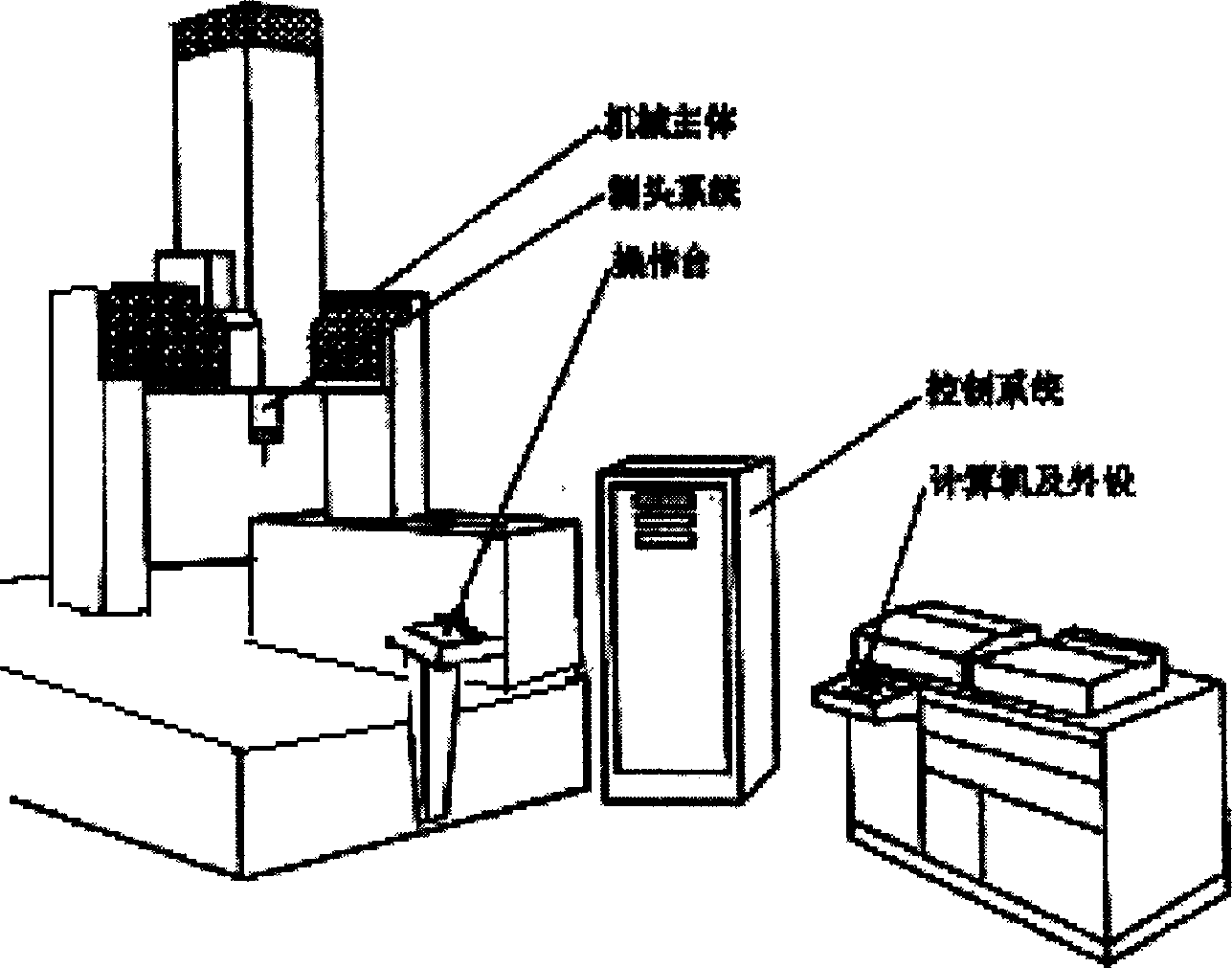

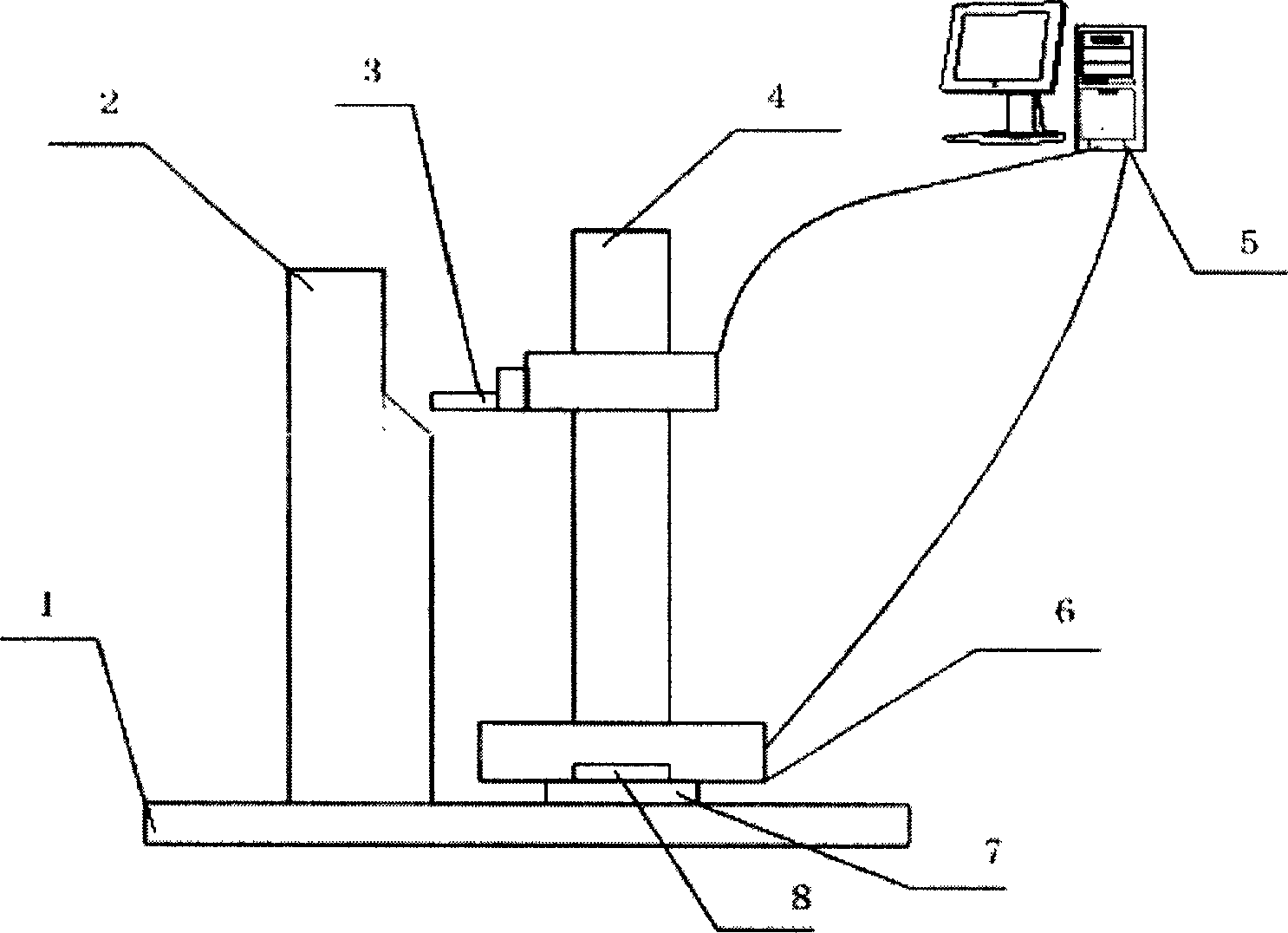

[0046] Such as figure 2 As shown, the present invention, as a virtual coordinate measuring machine based on data image processing, includes a working platform, a mechanical body, a measuring head, a computer and its peripherals, the measuring head is installed on the vertical shaft of the mechanical body, and an image acquisition device is also included. The granite platform is used as the working platform 1, because the deformation of the granite due to the influence of temperature is small. The main body of the machine is mainly composed of an air-floating slide 6, a vertical shaft 4, a measuring head 3 and a CCD camera 8. The image acquisition device is mainly composed of a CCD camera 8, a light source and an acquisition card 9. The air-floating slide 6 is perpendicular to the granite workbench. The vertical shaft 4, the cylinder and the measuring head are installed on the vertical shaft 4, which can move up and down along the vertical shaft and can be locked at any positi...

Embodiment 2

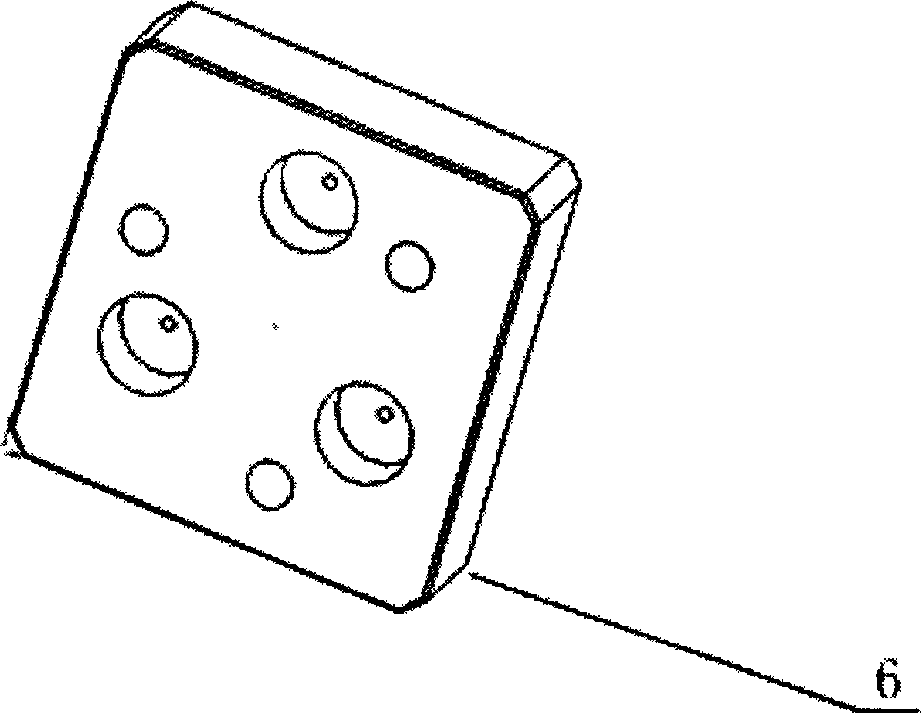

[0049] The overall composition and connection relationship are the same as in Embodiment 1, and there are 6 holes downwards on the air bearing slide 6 of the virtual coordinate measuring machine based on data and image processing, see image 3 , there are three holes evenly distributed along two different radial directions, and the three large holes are equipped with three air bearing sliders, that is, air static pressure bearings, which specifically adopt the circular air static pressure bearings developed by Xi'an Industrial Institute; The CCD camera 8 in the image acquisition device is installed in the hole. In order to ensure the high reliability of the measurement system, the present invention adopts an air-floating slide seat, a mechanism carrying multiple technical elements, on which a vertical shaft 4 and a measuring head 3 are installed, and a camera 8 and an air-floating block are installed under it, and the air-floating block That is, the aerostatic bearing has the ...

Embodiment 3

[0051] Overall composition and connection relation are the same as embodiment 1, as figure 2 As shown, the laser scanning probe is installed at the position where the probe 3 is installed in the figure, and the laser scanning probe is mainly used for non-contact measurement of soft materials or some characteristic surfaces. The measuring head is at a certain distance (such as 50mm) from the detection workpiece, and measures within a certain range of its focal point, and the sampling rate is above 200 points / second. Higher accuracy is obtained through the average processing function of a large amount of collected data. The application aspect of the present invention is expanded by installing the laser scanning measuring head, and the measuring ability for special materials is improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com