High frequency switch transformer

A high-frequency transformer and high-frequency switch technology, applied in the direction of transformer/inductor cooling, transformer/inductor coil/winding/connection, etc., to achieve the effect of low temperature rise, solving skin effect and cooling requirements, and improving heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

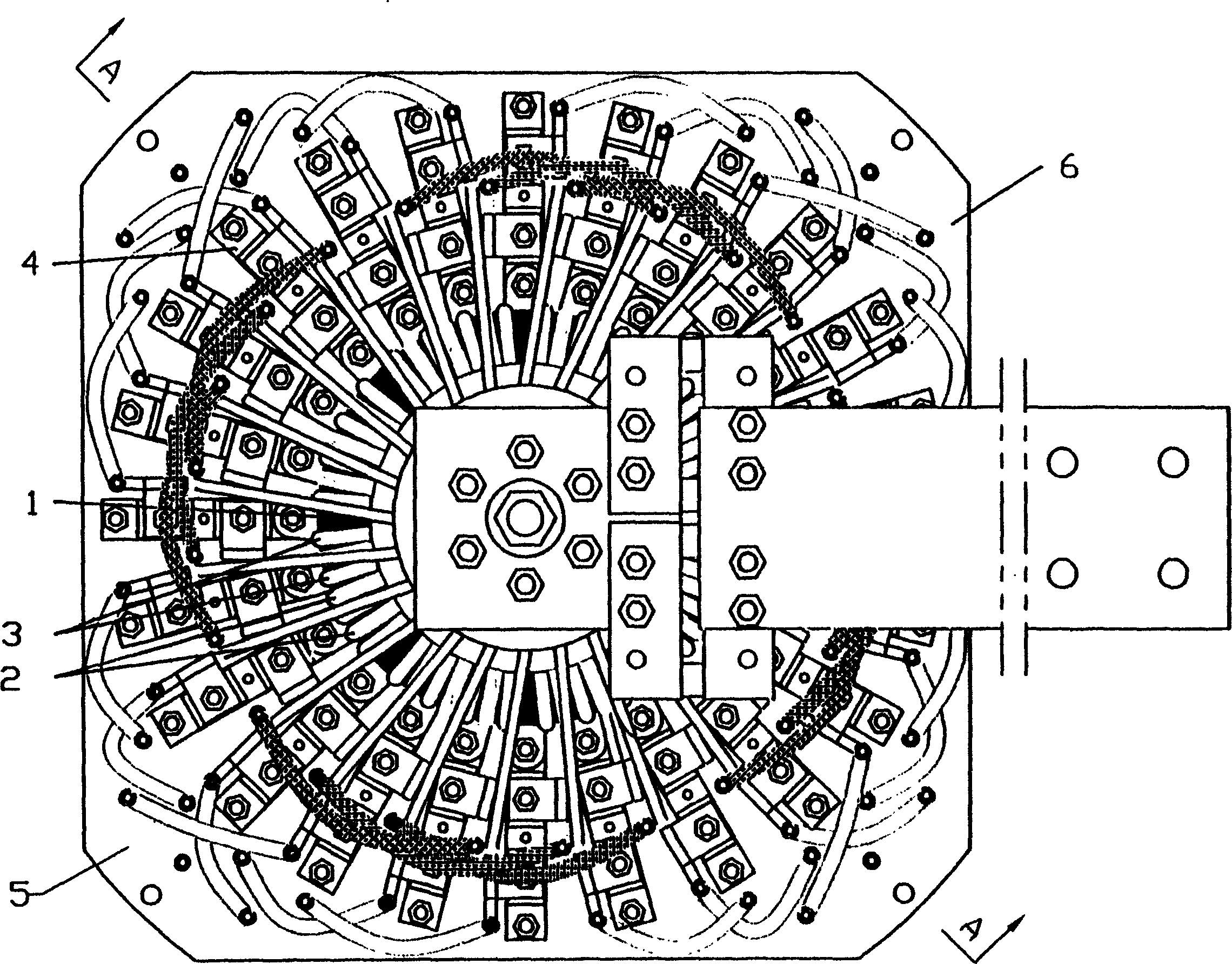

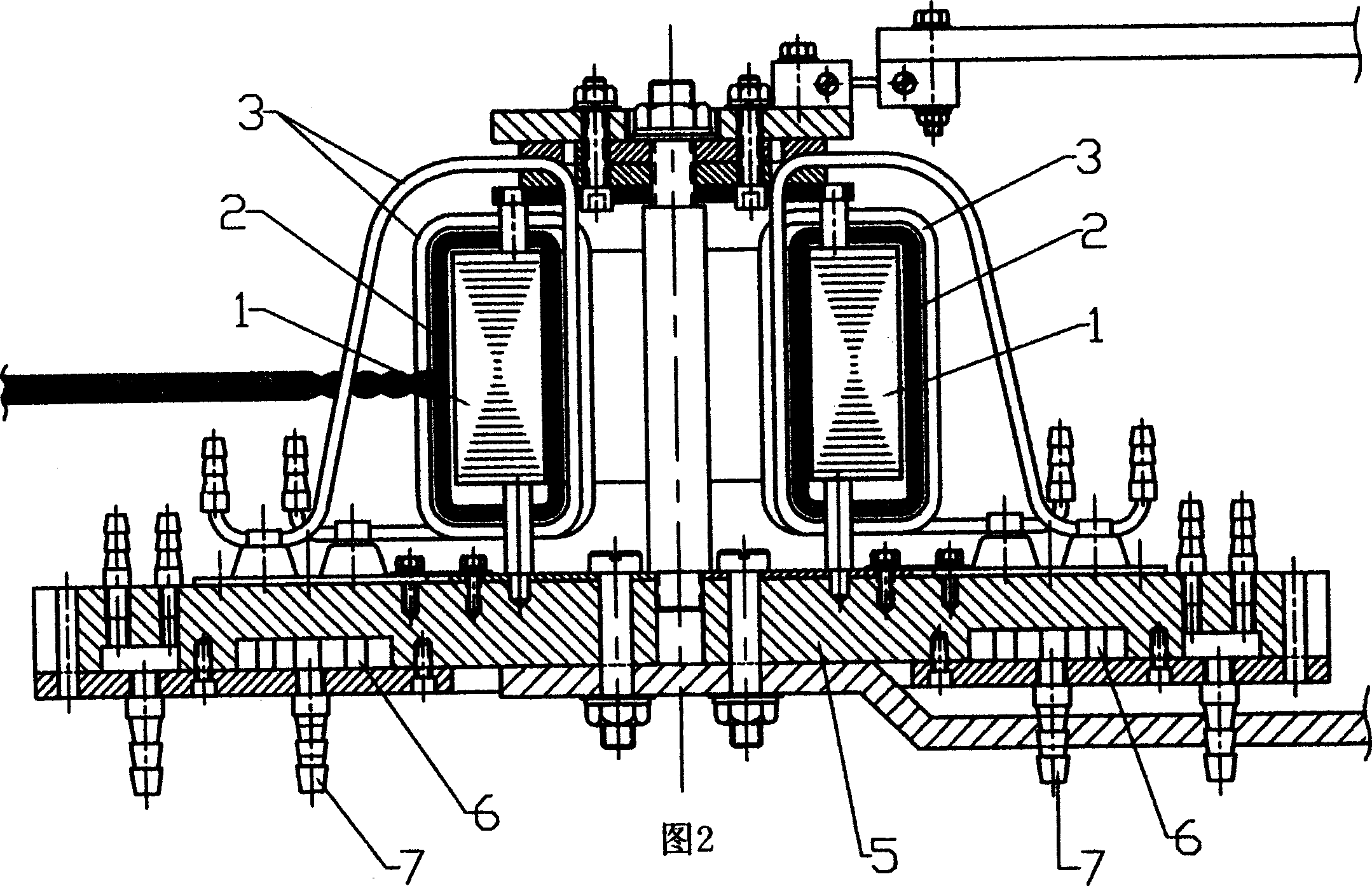

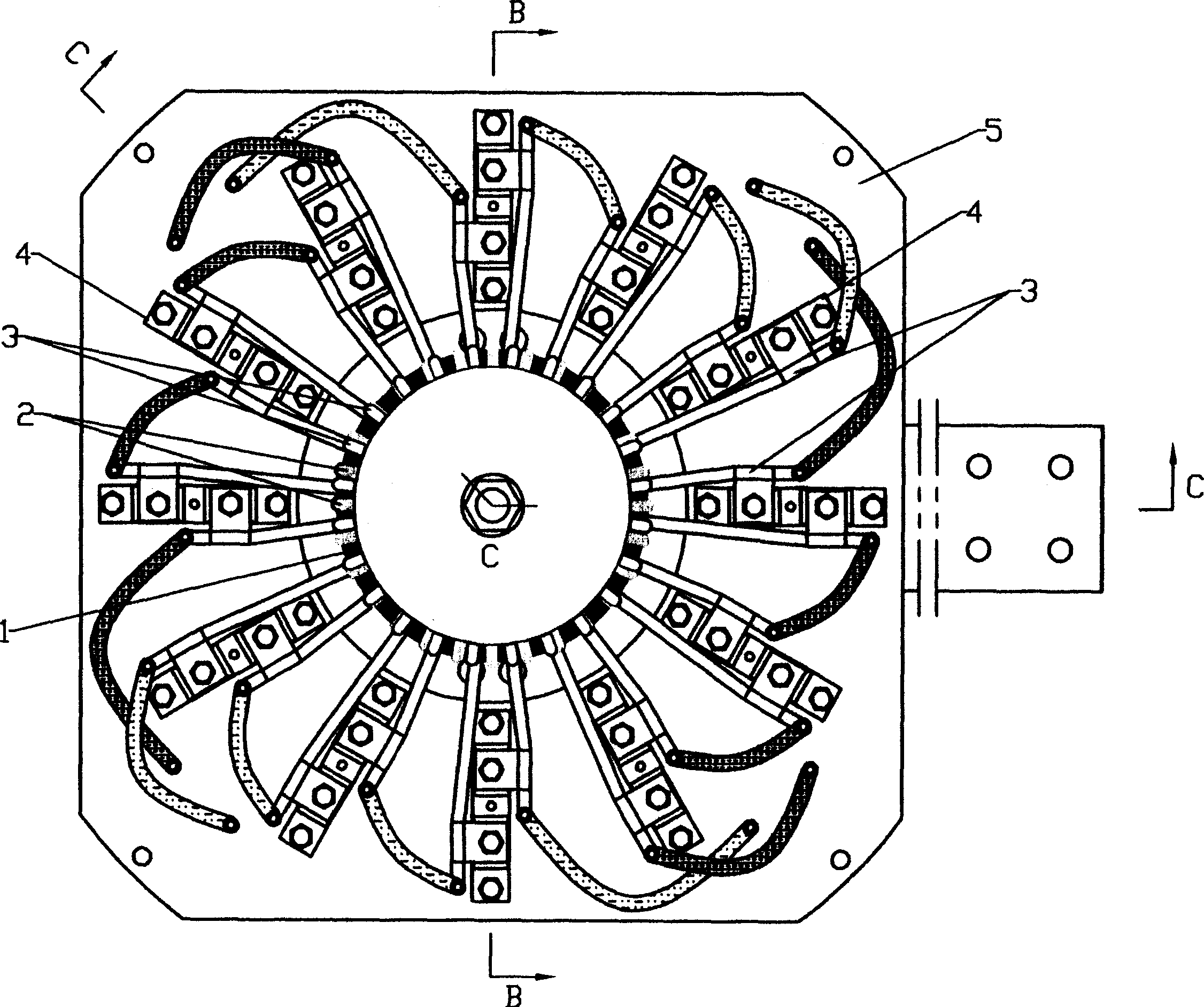

[0017] refer to figure 1 , Figure 2, a high-frequency switching transformer, the primary winding 2 and secondary winding system of the high-frequency transformer are formed by winding a hollow copper tube on a high-frequency magnetic core 1. The secondary winding system is composed of a plurality of individual secondary windings 3 connected in parallel, each individual secondary winding 3 and the primary winding 2 are evenly wound on the high-frequency magnetic core 1 in an alternate manner, and each high-frequency rectifier tube 4. Taking the central axis of the high-frequency switching transformer as the axis, they are evenly distributed radially and radially, and are connected to the individual secondary windings 3 in one-to-one correspondence.

[0018] When in use, the cooling water is connected to the nozzle 31 of the copper tube forming the secondary winding and the end of the copper tube forming the primary winding, which well solves the skin effect and cooling requirem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com