Cold light piece driving circuit

A driving circuit and cold light chip technology, applied in the field of electricity, can solve the problems that it is difficult to ensure the stable operation of the driver, affect the service life of the driver, have no overvoltage, overcurrent and overheat protection, etc., and achieve rich flashing, light weight, and small size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

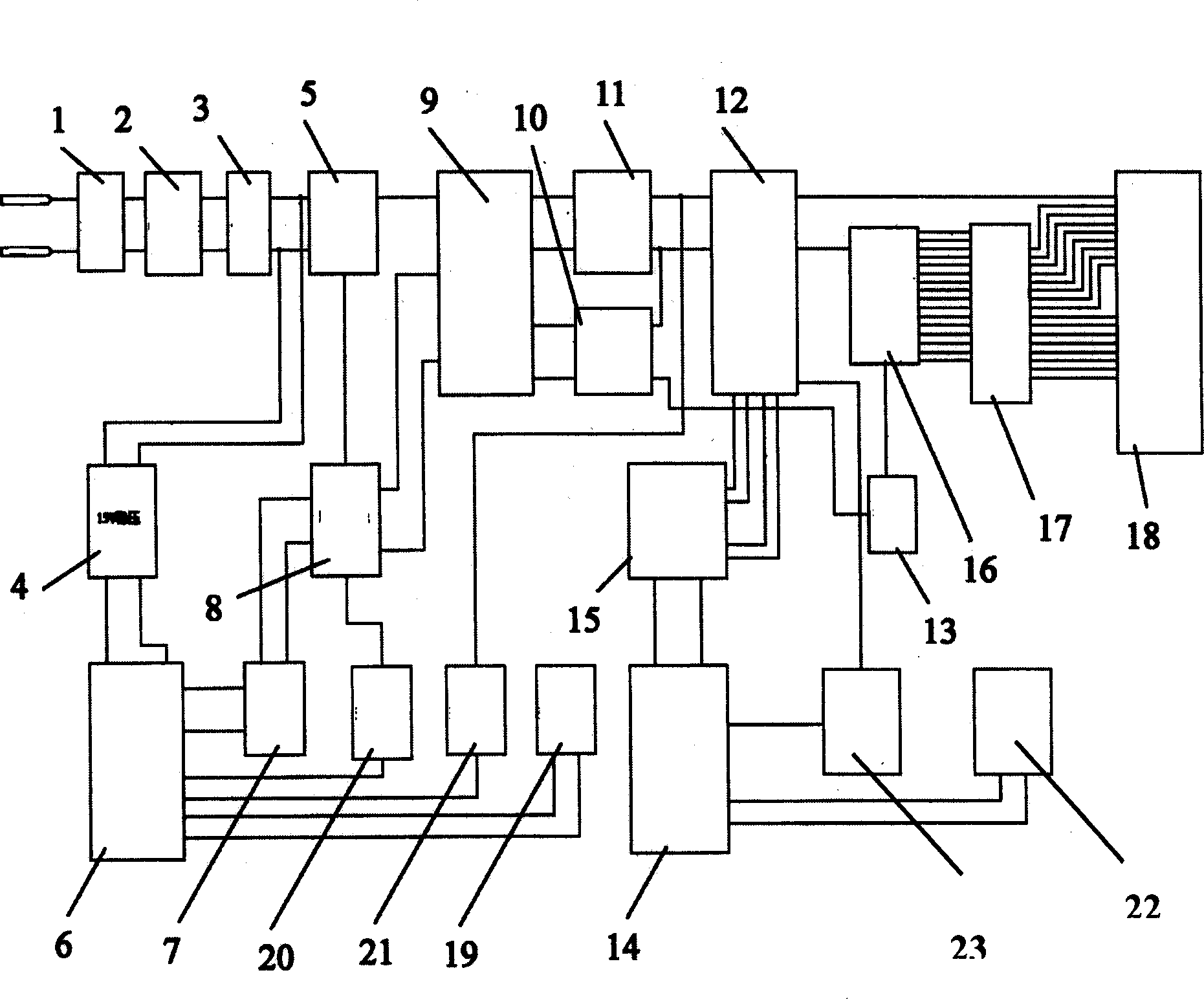

[0010] Such as figure 1 As shown in Fig. 2, the EL driving circuit of the present invention is composed of a power input circuit, a load output circuit, a transformer circuit, a first PWM pulse width modulation circuit, a second PWM pulse width modulation circuit, an inverter Circuit and a single-chip microcomputer control circuit 16 constitute, described power supply input circuit, load output circuit, transformer circuit, the first PWM pulse width modulation circuit, the second PWM pulse width modulation circuit, inverter circuit and single-chip microcomputer control circuit are all arranged on On the circuit board, wherein the power input circuit is composed of a DC power input terminal 1, a power switch 2 and a fuse 3, and the DC power input terminal 1 is connected to the fuse 3 through the power switch 2, The power input circuit is connected with a first voltage stabilizing circuit 4, and the first voltage stabilizing circuit 4 is connected with the first PWM pulse width ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com