Soil membrane forming mixture

A technology of mixture and powder mixture, applied in the direction of plant protection, plant protection cover, botanical equipment and methods, etc., to achieve the effect of improving soil and strong flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

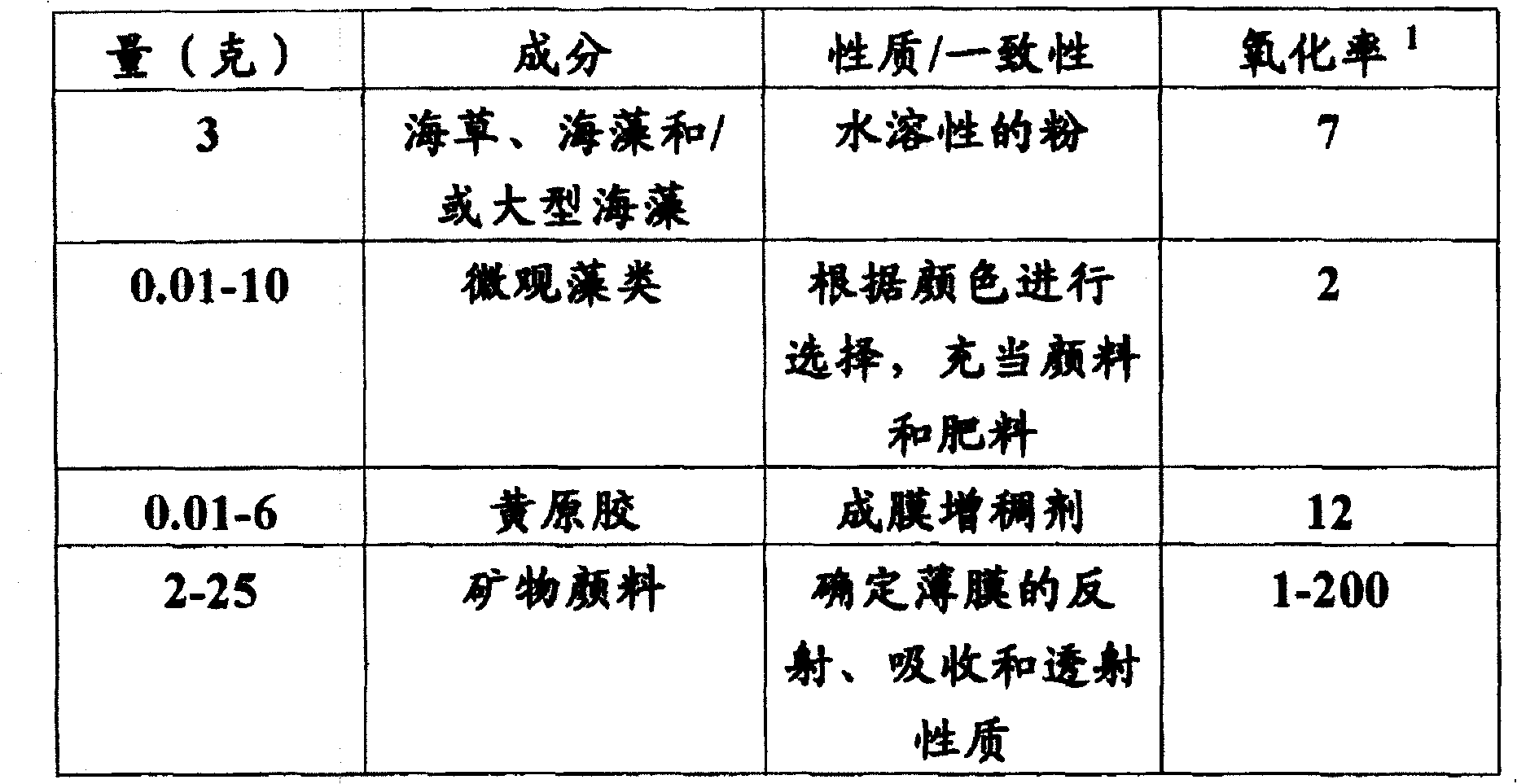

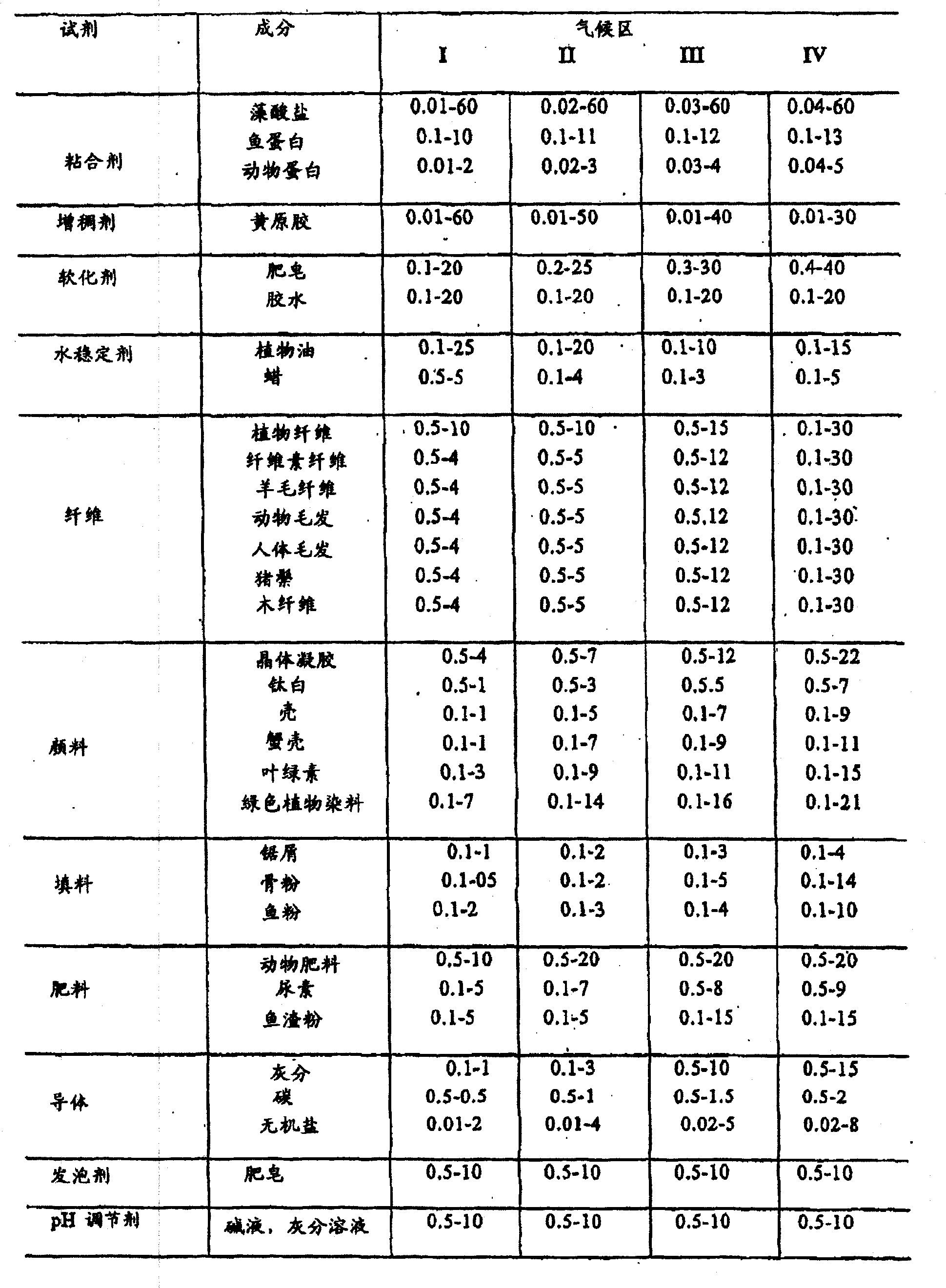

Method used

Image

Examples

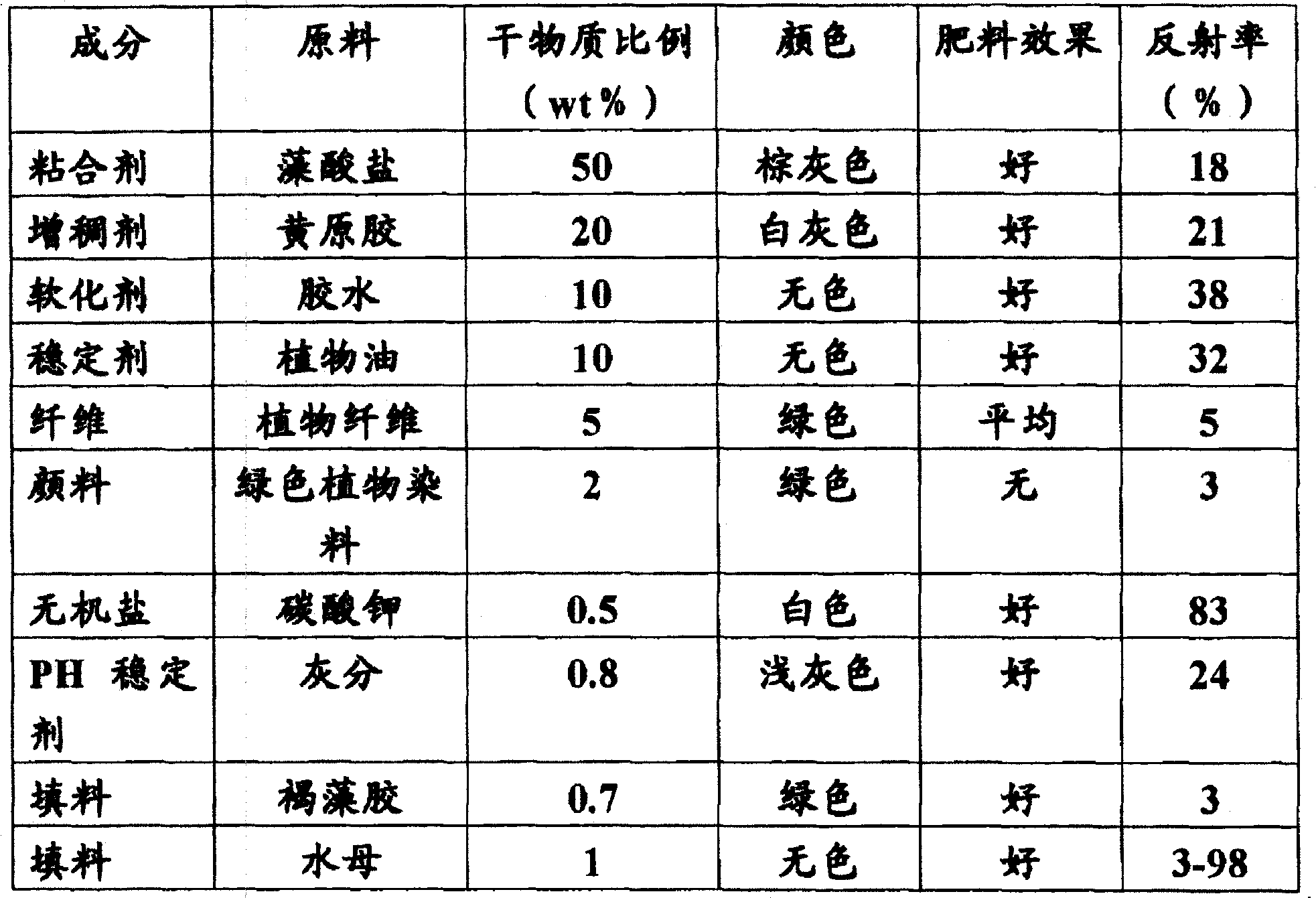

Embodiment 1

[0119] Example 1 Preparation of dry powder mixes for Scandinavian climate zones

[0120] The dry powder mix of this example is intended for use in forming surface films that act as growth promoting devices in agriculture and other industries where soil temperatures are 5-15°C during spring tillage in relatively cold climates where useful plants grow. The film is spread with ground preparation in the spring prior to planting useful plants and should have a physical lifespan that lasts until the plants are established and grown tall enough to block the film from receiving incident sunlight. This membrane should then break down and become nutrients for the plant. This means that the lifespan of this membrane is 1-2 months, depending on the amount of germination, humidity and microbial density and activity. It is assumed that for this climate zone, the pigment composition should absorb sunlight to a greater extent than bare soil (less than 5% reflectivity), thereby increasing roo...

Embodiment 2

[0128] Example 2 Prefabricated dry powder mixes for southern European climate zones

[0129] The powder mix of this example is intended for use in agriculture and other industries where useful plants grow in relatively hot and dry climates, forming surface films that act as growth promoting devices. Typical soil temperature is 15-35°C, which means that the film should be used to reduce soil temperature. A general problem in this climate zone is drought and associated surface erosion, which means that the membrane should be used to moderate the evaporation of moisture from the soil and to bind surface particles together. This is achieved by using lighter pigments than in Example 1 and a relatively high proportion of fibers, preferably light colored fibers, to give the membrane a greater ability to bind loose soil together.

[0130] The film is spread during preparation of the soil for sowing and should have a physical lifespan that lasts until the plants are fully grown and ne...

Embodiment 3

[0139] Example 3 Prefabricated dry powder mixes for equatorial climate zones

[0140] The powder mix of this example is intended for use in agriculture and other industries where useful plants grow in equatorial climates, forming surface films that act as growth promoting devices. The general soil problems in this geographic region (eg, Central America) are mainly high soil temperatures and strong erosion during the dry season and low and wet soil temperatures during the rainy season, so the purpose of employing this membrane in this case is to represent The strength of the mechanical properties of vegetation and soil surfaces determines reflectance to control soil temperature and water evaporation.

[0141]The membranes in such areas are given color to obtain the desired degree of reflection, thereby regulating the soil temperature to the desired level. We believe that for equatorial climates, the pigment composition must / should reflect sunlight to a greater extent than bare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com