Double thrust disc and double regulating caliper type pneumatic brake device capable of self-regulating braking clearance

A brake gap and air pressure brake technology, applied in the direction of slack adjuster, brake type, axial brake, etc., can solve the problems of high machining accuracy requirements for automatic adjustment arms, increased brake cost, and brake dragging. Achieve the effect of easy automatic adjustment of clearance, small structure size and stable braking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

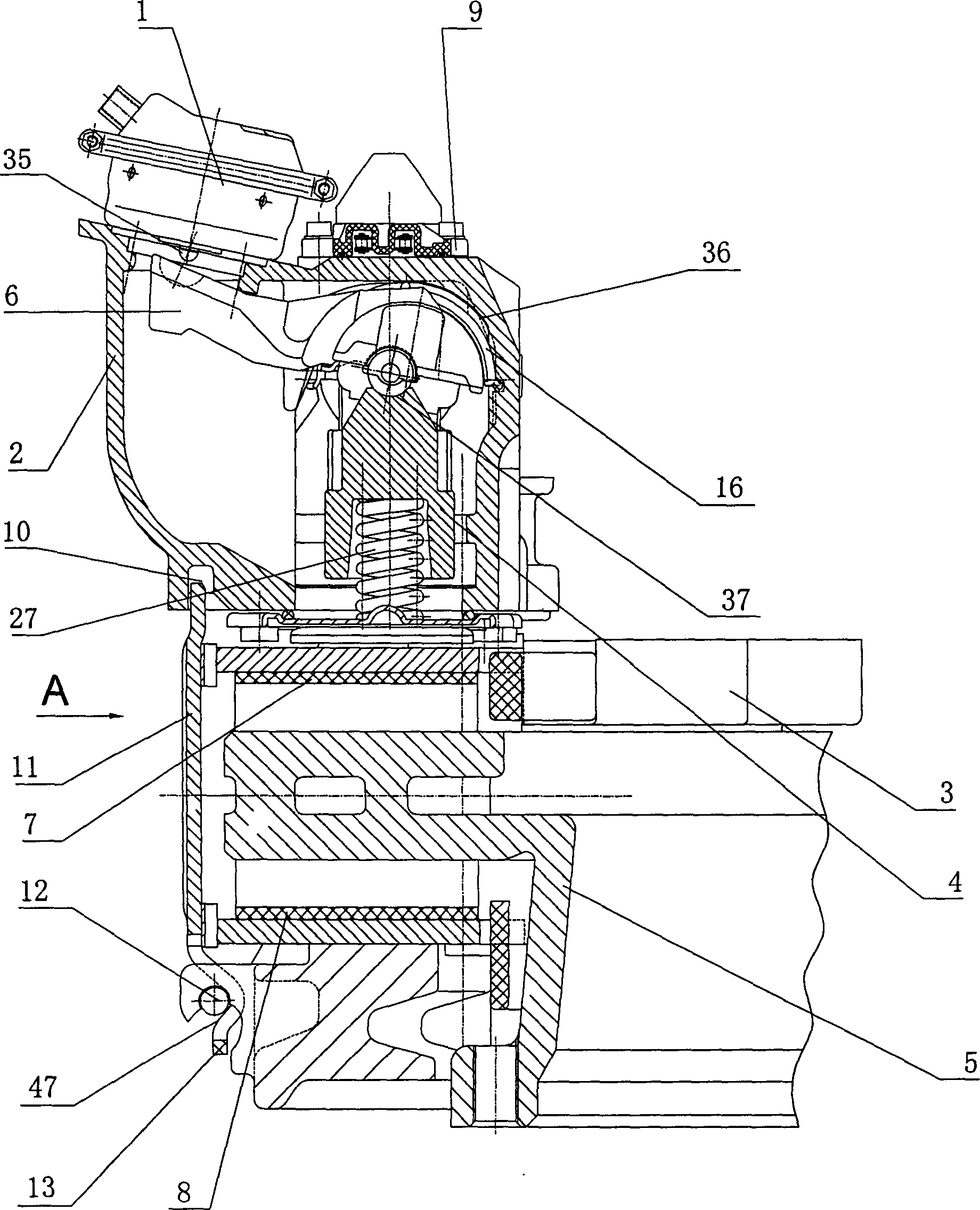

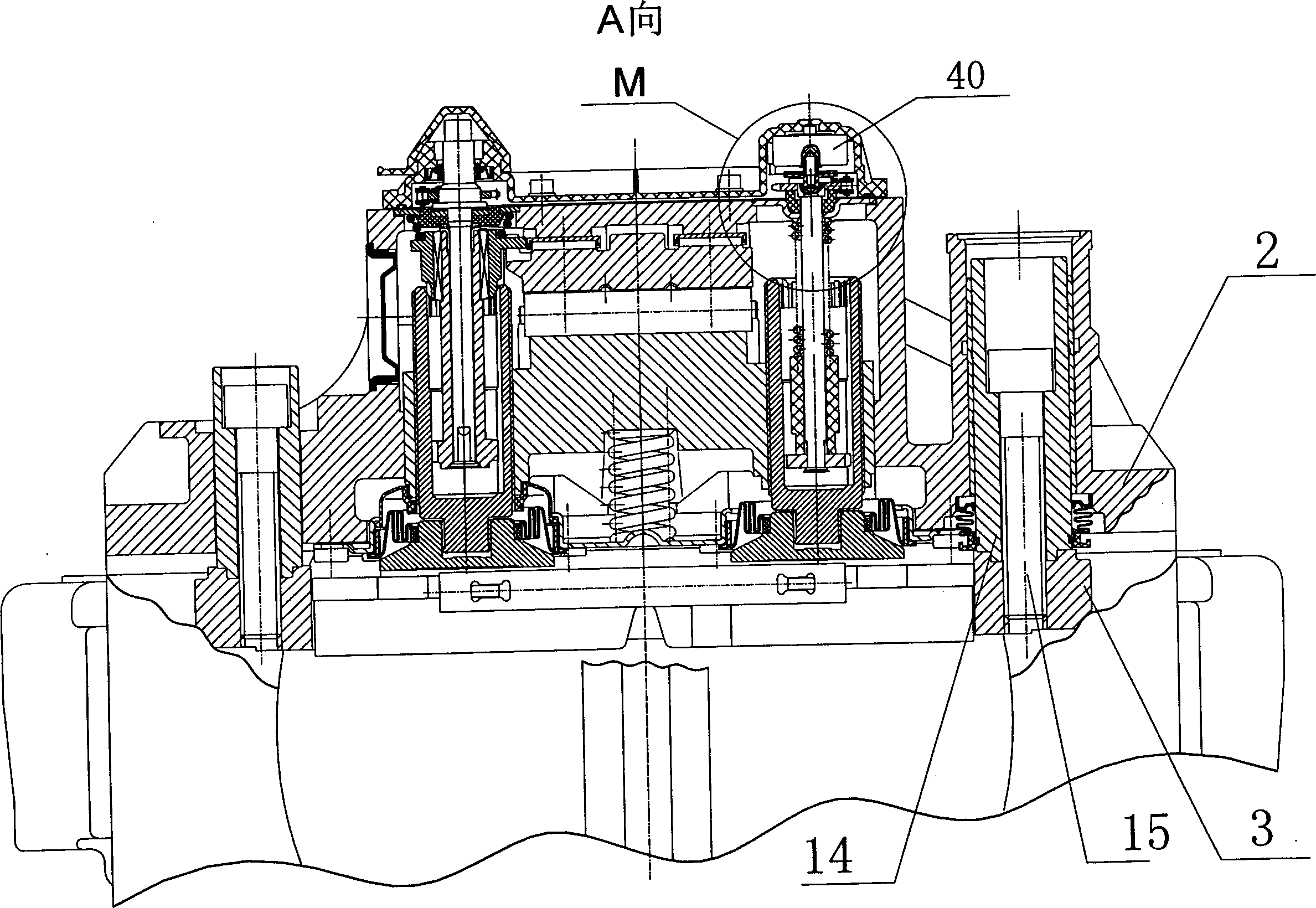

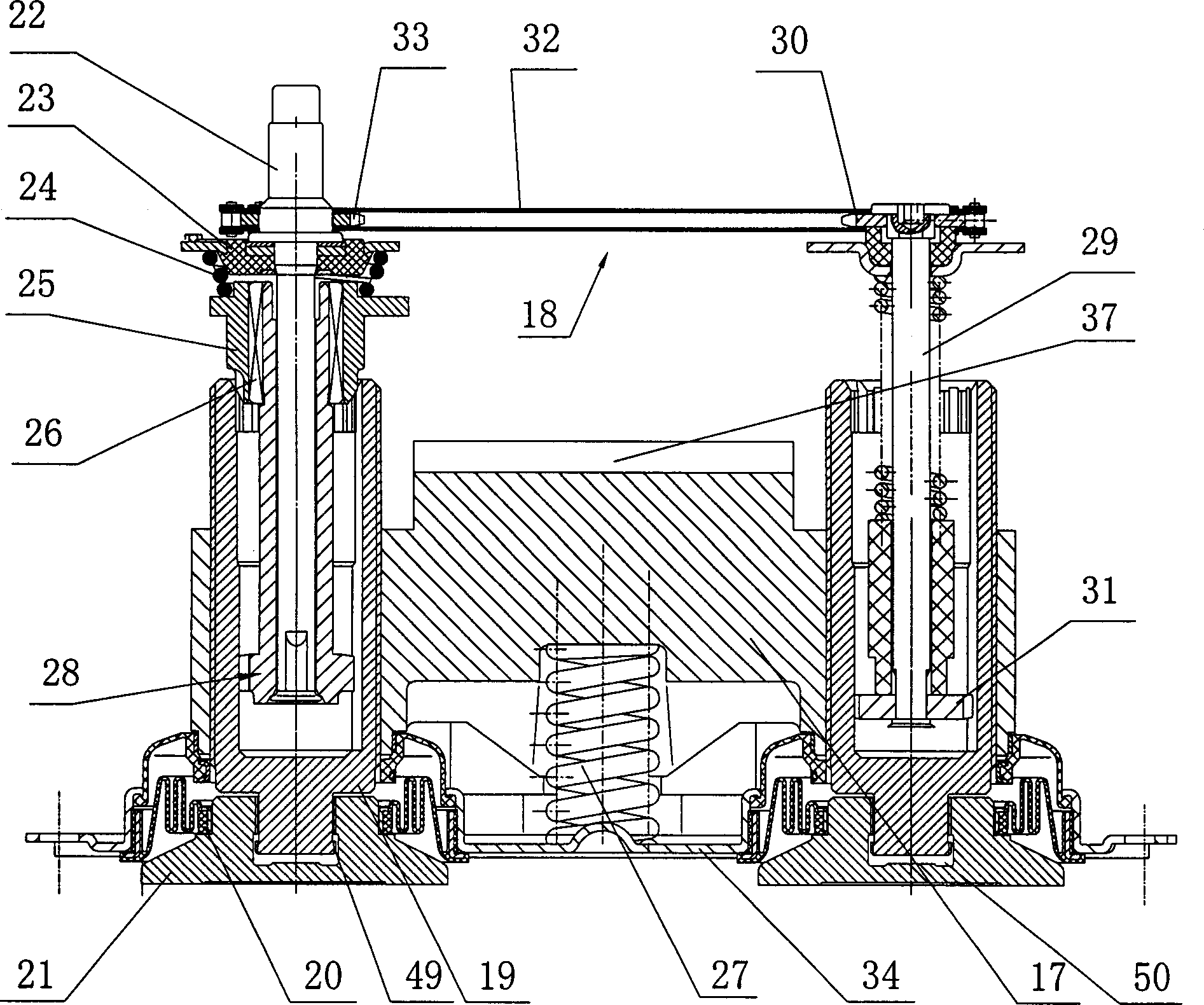

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0024] control figure 1 , figure 2 , the brake caliper body 2 is placed on the brake bracket 3, the brake caliper body 2 is provided with a guide hole, the brake bracket 3 is connected with the guide sleeve 14 by a screw 15, and the brake caliper body 2 passes through the guide hole on the guide hole. The sleeve 14 moves relative to the brake bracket 3, see figure 2 . The brake air chamber 1 is placed on the upper end of the brake caliper body 2, and the tappet 35 on it extends into the upper side of the inner cavity of the brake caliper and is crimped on one end of the lever 6, and the other end of the lever 6 is provided with a semicircular block 44 ,See image 3 , the semicircular block is rollingly connected to the inner ring of the needle bearing 16, and the needle bearing 16 is installed on the semicircular bearing seat hole of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com