Optical spot grid array printer

A lithography machine and array technology, which can be used in optomechanical equipment, microlithography exposure equipment, optics, etc., and can solve problems such as unimproved resolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

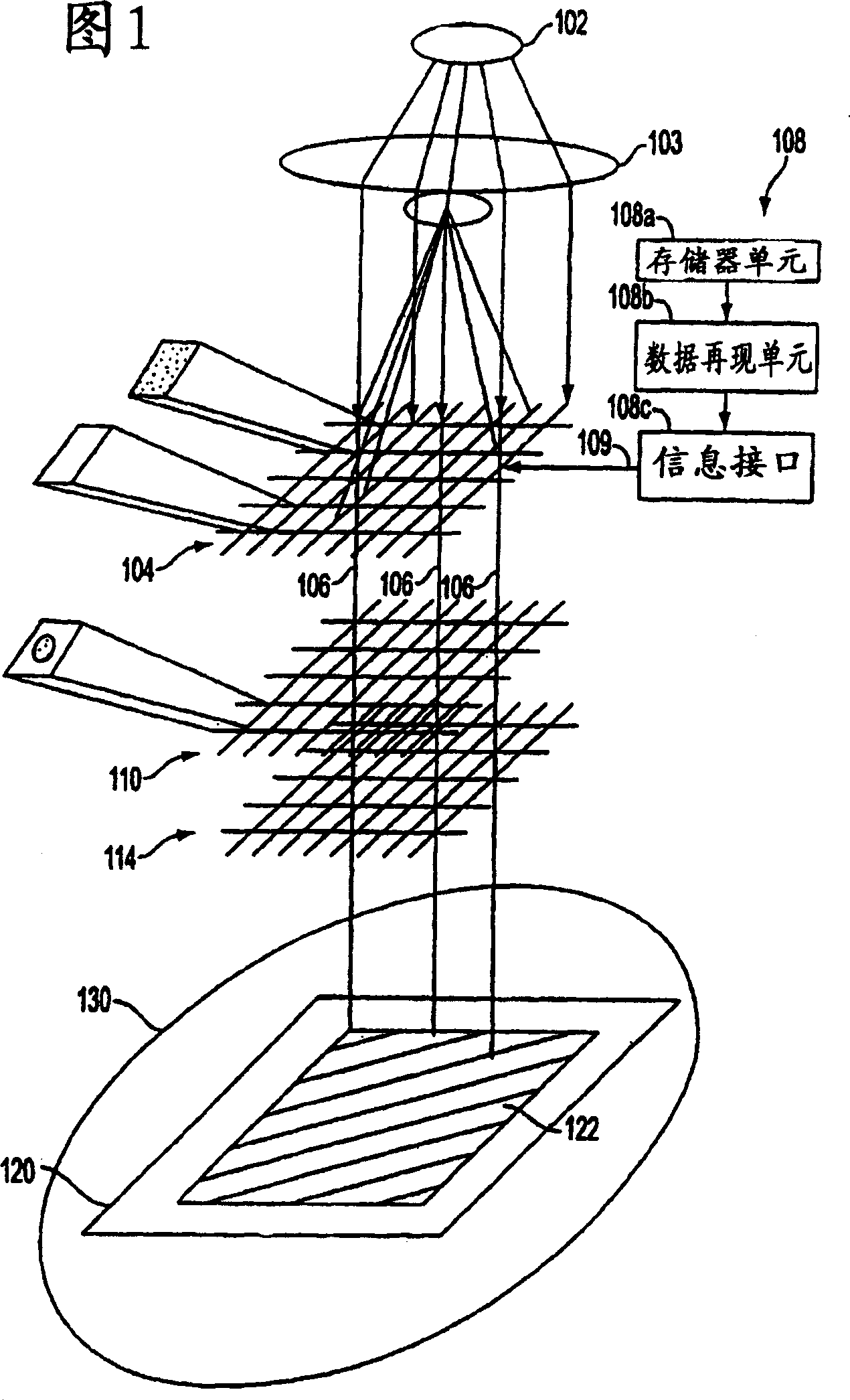

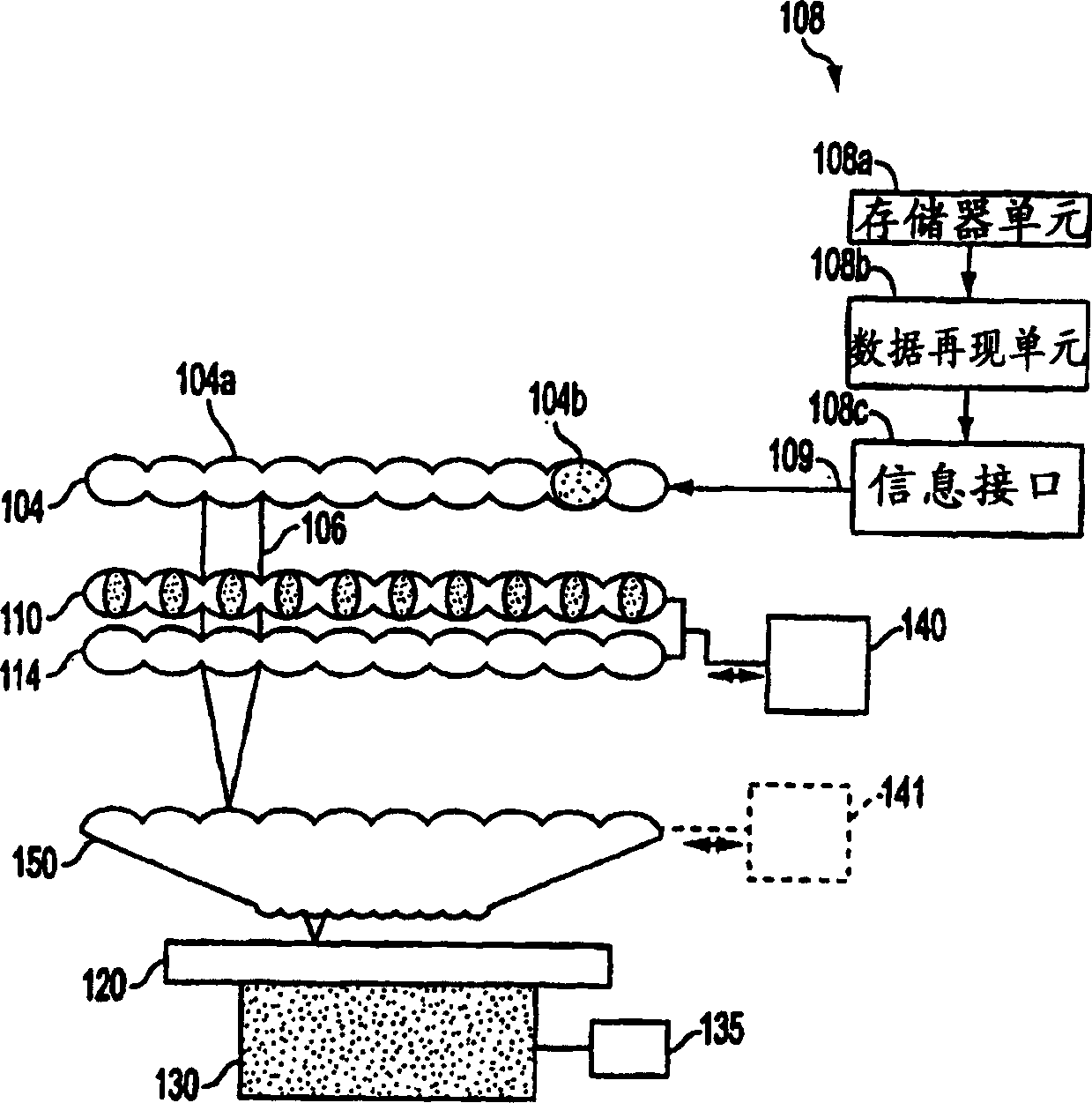

[0032] FIG. 1 shows a photolithography machine according to a first embodiment of the present invention. The lithography machine includes: a light source 102, which may be a continuous wave laser or a pulsed laser; a collimating optical device 103; and a spatial light modulator (SLM) 104, which is used to provide and modulate a two-dimensional array of parallel beams 106 . In response to input data signals 109 provided by programmable image generator 108 , spatial light modulator 104 modulates the beams and controls each beam in synchronization with control stage 130 to expose a desired pattern on substrate 120 . The machine further includes a beam shaper array 110 interposed between the spatial light modulator 104 and the substrate 120 for narrowing each beam 106 to improve resolution. Focusing optics 114 provide a lens element for each beam 106 and focus each beam into small spots on substrate 120 to form a grid array of spaced spots on substrate 102 . The substrate 120 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com