Method for regenerating water-glass old sand

A technology for regenerating old sand and water glass, applied in casting molding equipment, metal processing equipment, manufacturing tools, etc., can solve the problem of deteriorating high temperature performance of water glass type (core) sand, deterioration of high temperature performance of water glass type (collapse and fire resistance) problems such as speed, to achieve great application value, the effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

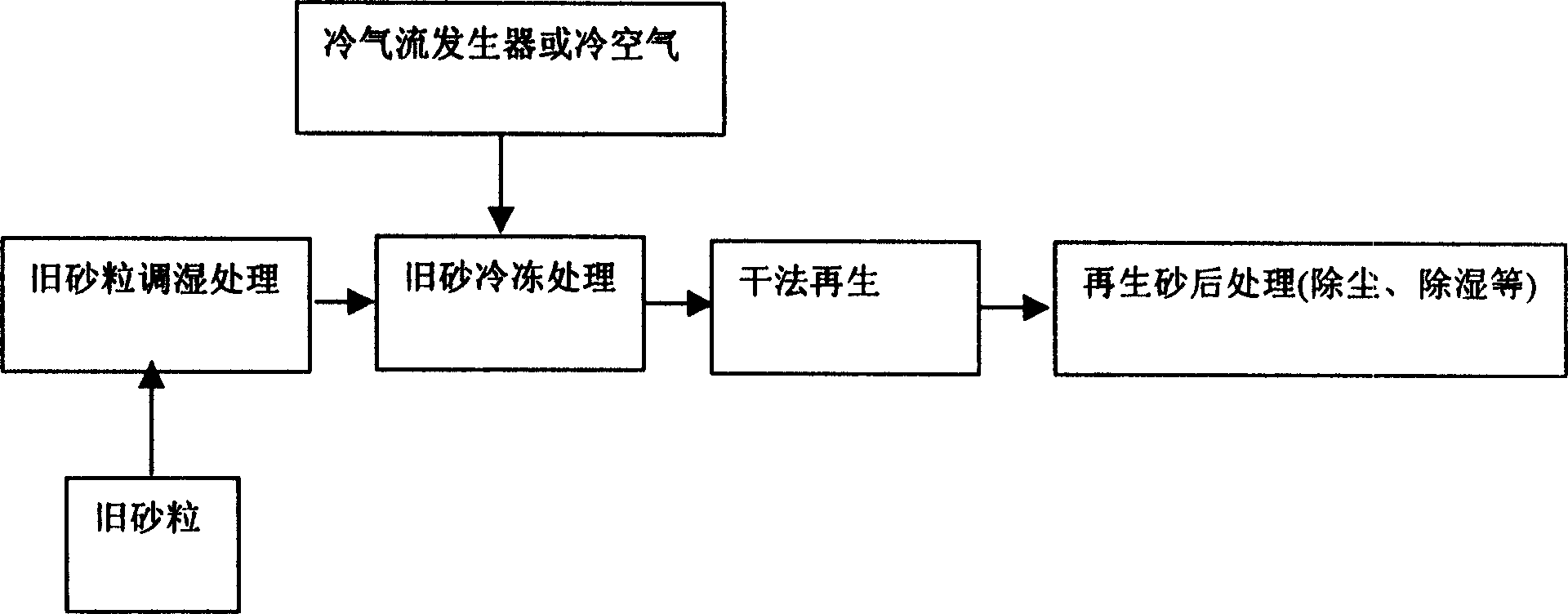

[0020] Break the old water glass sand into sand grains, add water to the old sand to make the water content of the wet old sand 0.5%, use the natural air-conditioning outdoors in winter, introduce the old sand and air-conditioning into the mixing chamber and freeze it to a temperature of -1°C , and then perform mechanical centrifugal dry regeneration on the frozen and cooled water glass old sand, and exhaust and dust removal during the regeneration process to remove the residual components on the surface of the water glass old sand, and obtain regenerated water glass sand after humidity adjustment and temperature adjustment, ready for use .

Embodiment 2

[0022] Break the old water glass sand into sand grains, add water to the old sand to make the water content of the wet old sand 10.0%, use a scroll refrigeration compressor to refrigerate, and introduce the old sand and cold air into the mixing chamber to freeze and cool to the temperature - 60 ℃, and then carry out airflow impact dry regeneration on the frozen water glass old sand, and exhaust dust during the regeneration process to remove the residual components on the surface of the water glass old sand, and obtain the regenerated water glass sand after humidity adjustment and temperature adjustment. stand-by.

Embodiment 3

[0024] Crush the old water glass sand into sand grains, add water to the old sand grains to make the water content of the wet old sand 5%, use a screw refrigeration compressor to refrigerate, introduce the old sand and cold air into the mixing chamber to freeze and cool to -35°C , and then perform mechanical centrifugal dry regeneration on the frozen and cooled water glass old sand, and exhaust and dust removal during the regeneration process to remove the residual components on the surface of the water glass old sand, and obtain regenerated water glass sand after humidity adjustment and temperature adjustment, ready for use .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com