Digital controlled tracing welding machine tool

A welding machine tool and trajectory technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve problems such as complex systems, expensive products, and complicated operations, and achieve the effects of accelerated progress and development, reliable performance, and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

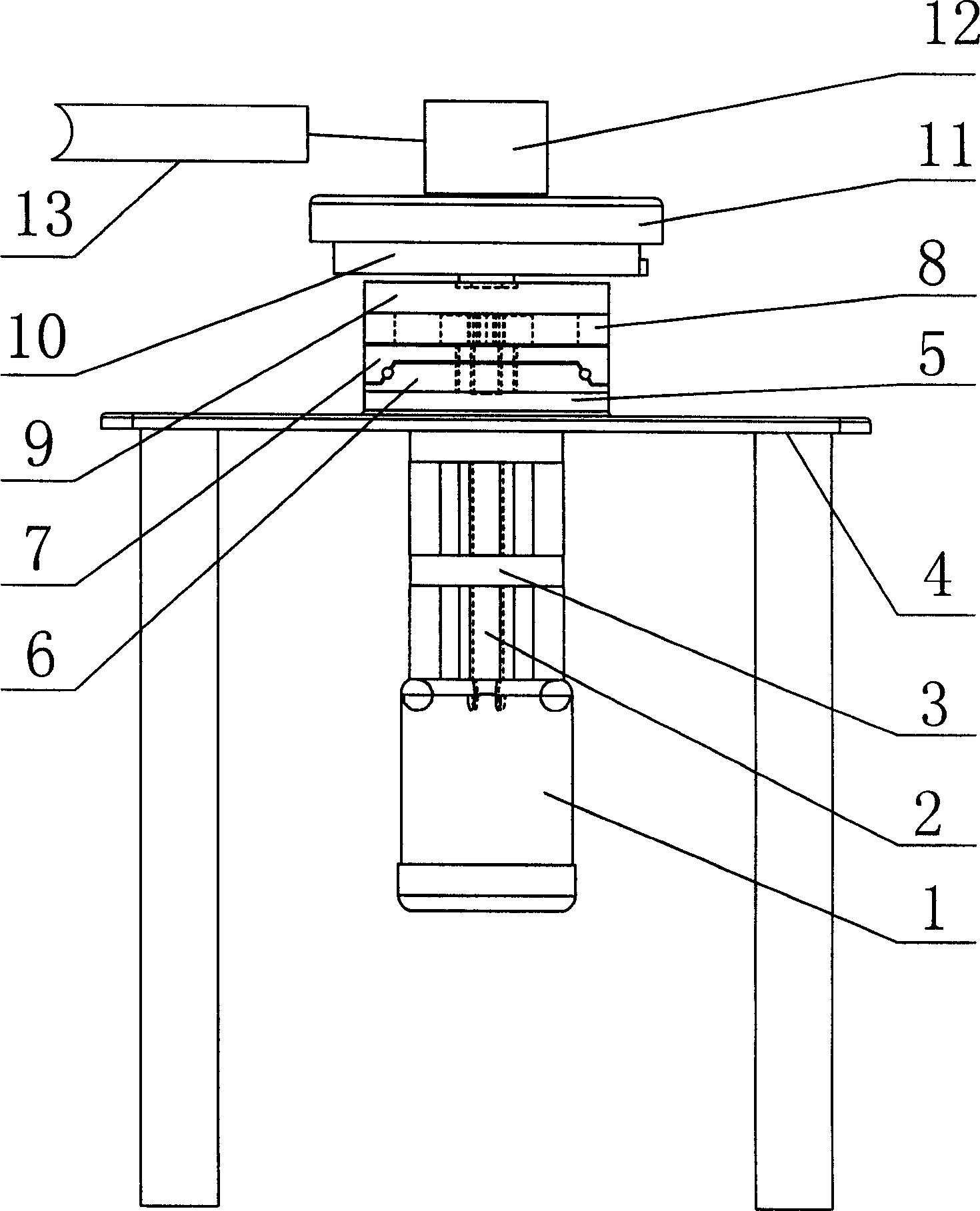

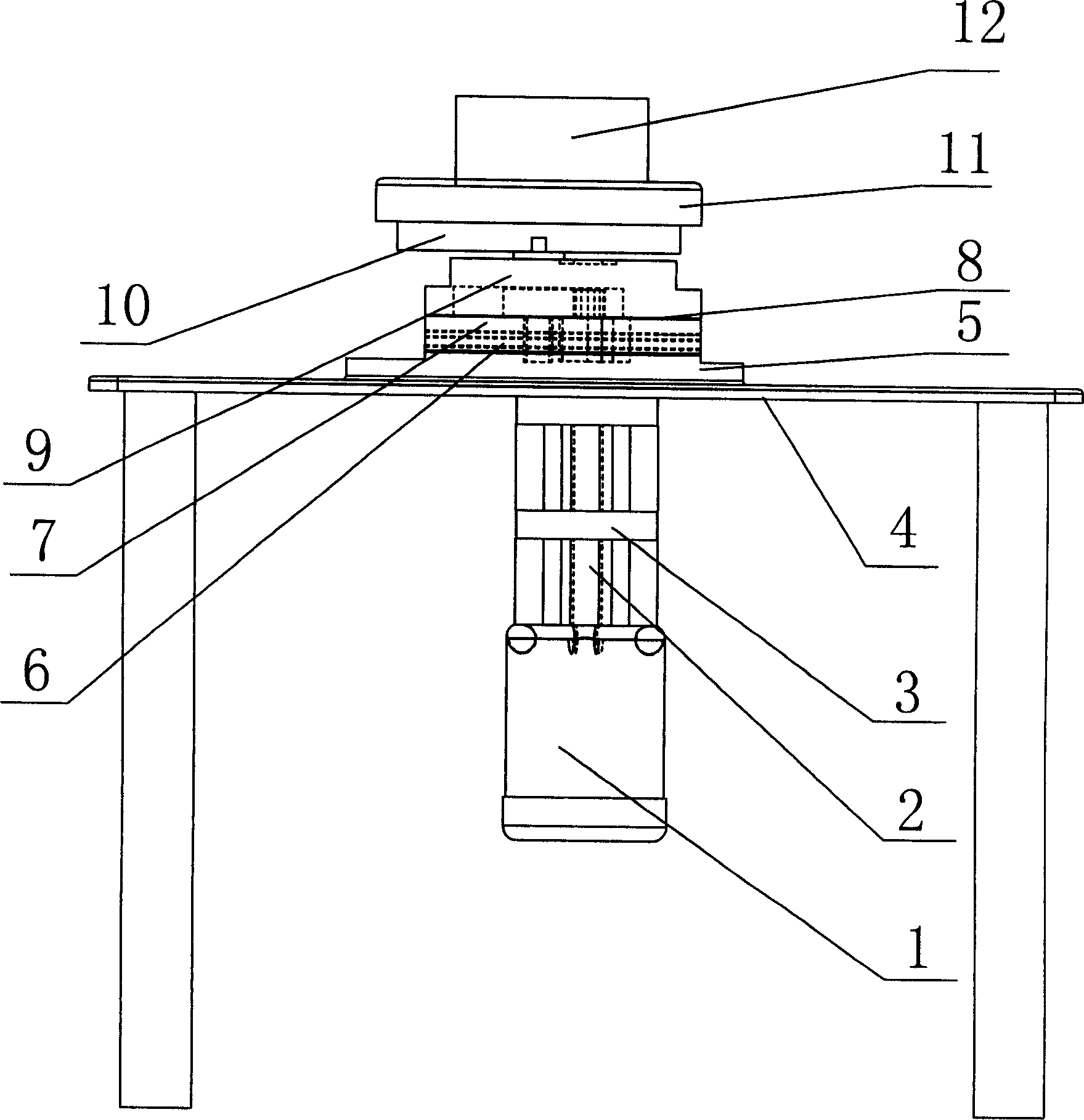

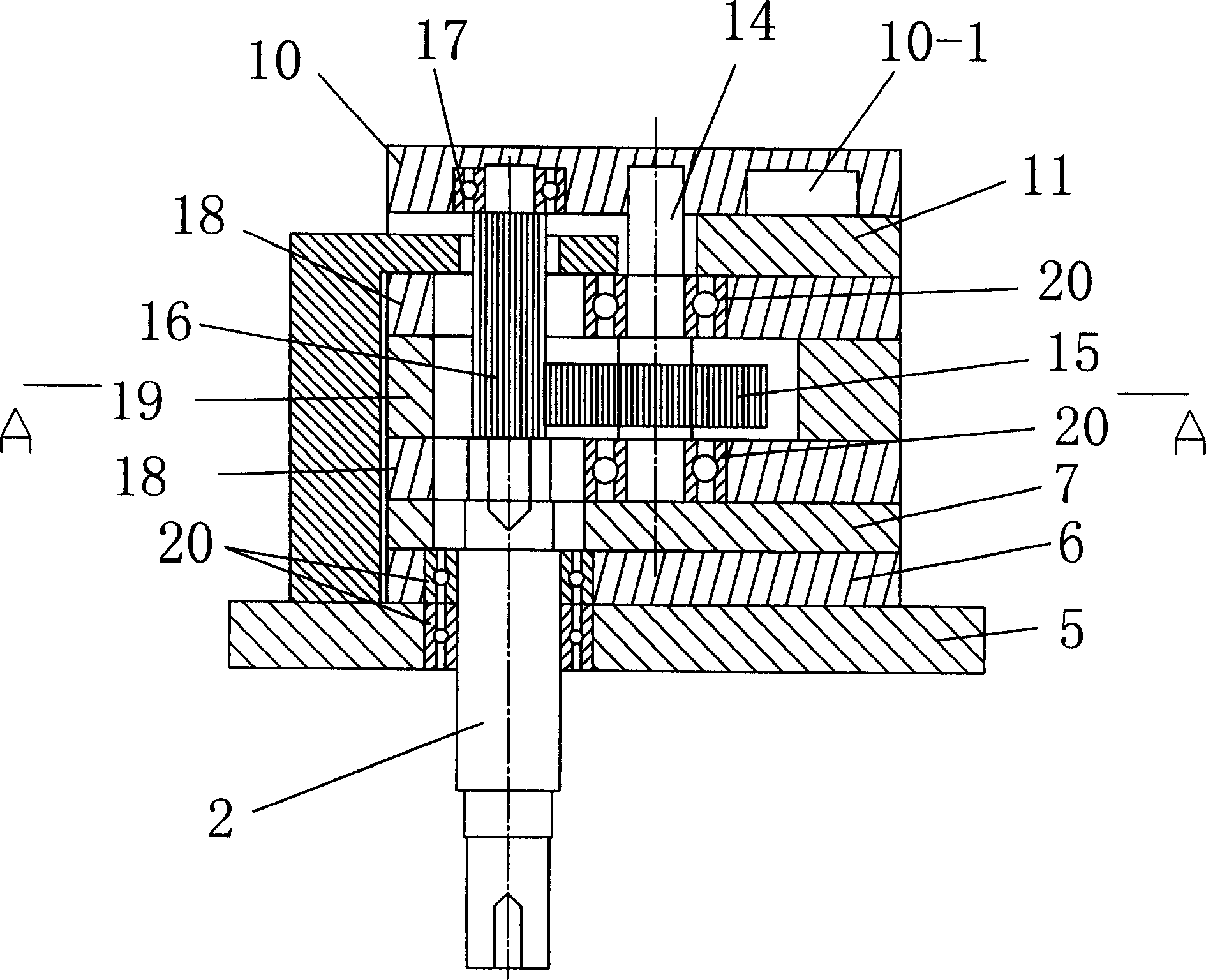

[0028] As shown in the figure, this CNC trajectory welding machine mainly includes a welding torch 13, a mechanical main frame 4 and fixtures, and a special-shaped welding workpiece 12 is fixedly connected to the worktable 11 through the fixtures. The bottom plate 5 is fixedly connected to the mechanical main frame 4, the bottom plate 5 is fixedly connected with the lower guide rail plate 6, and the lower guide rail plate 6 is provided with an upper guide rail plate 7 which is slidingly matched with it, between the lower guide rail plate 6 and the upper guide rail plate 7 A ball guide groove 21 is provided, in which a group of balls are placed so that the two form rolling friction. The upper guide rail plate 7 is sequentially connected with a gear case plate 8, a bearing fixing plate 9, a trajectory guide plate 10 and a worktable plate 11 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com