Fixing fusion device for vertebral bodies of lumbar

A technology for intervertebral bodies and fusion devices, which is applied in the direction of fixators, internal fixators, prostheses, etc., can solve problems such as unsatisfactory, and achieve the effects of convenient material collection, high compressive strength, and high image compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

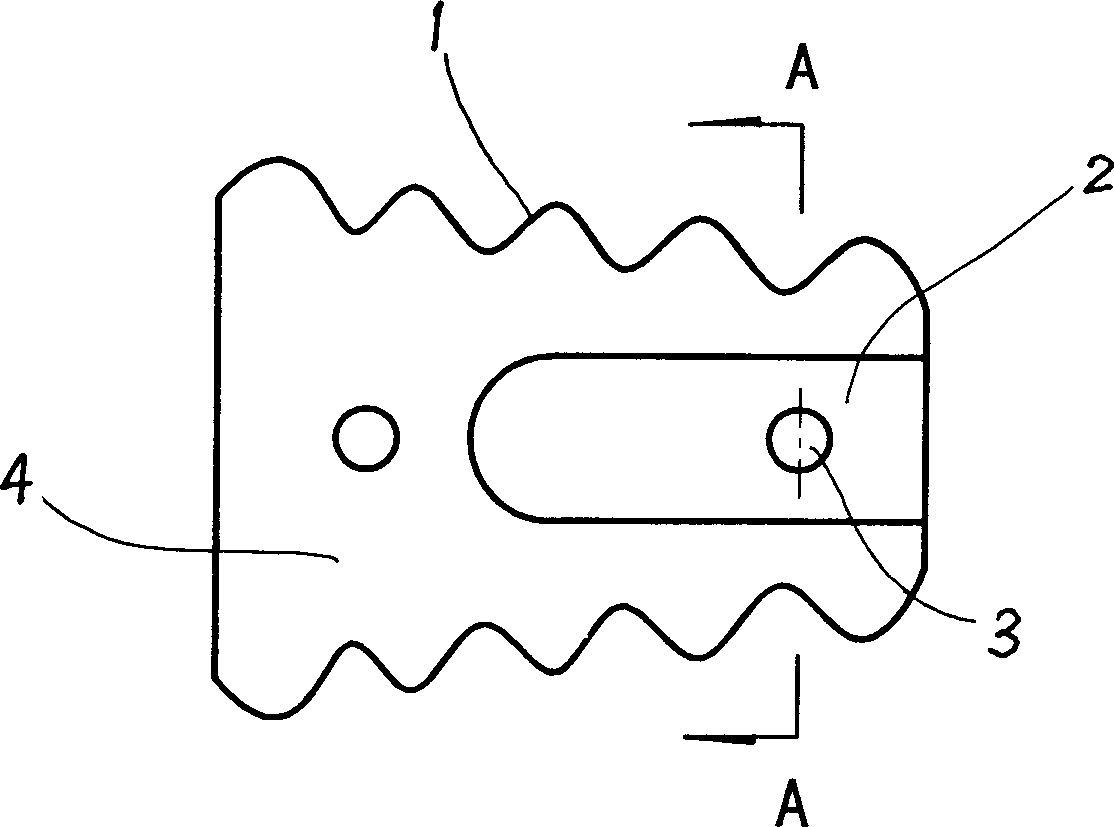

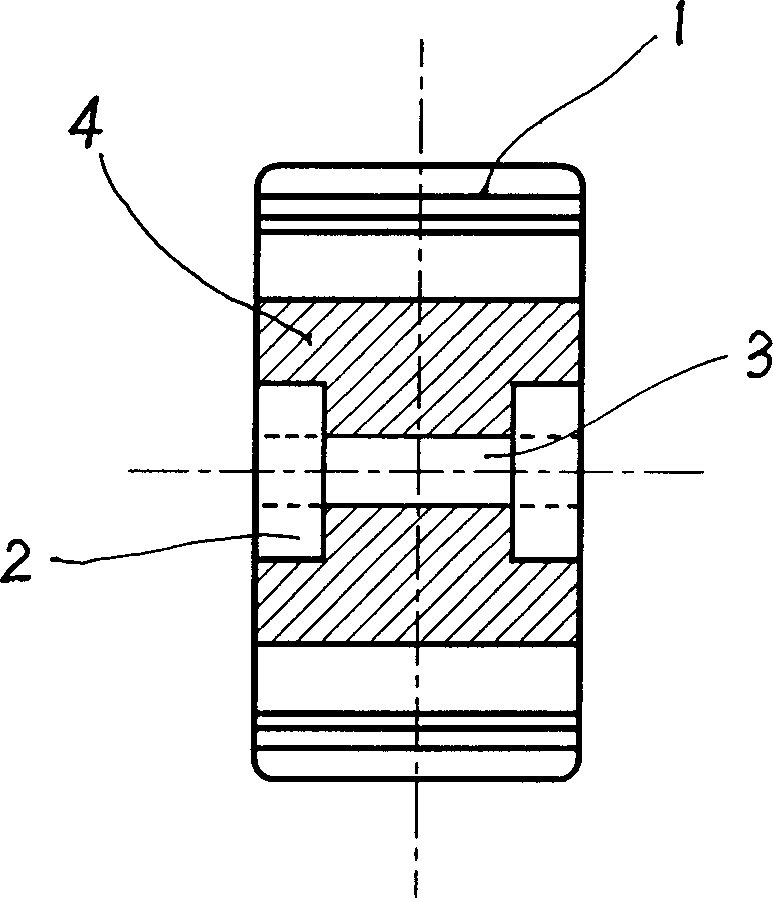

[0016] Example 1: In this example, bovine bone bone tissue is used as the material, and it is planed and milled into a cone-shaped body 4 with a height of 25mm, a lower bottom surface of 14mm, an upper bottom surface of 10mm, and a thickness of 10mm. The groove diameter is Φ6mm. The cross section of the groove is I-shaped. The vertebral surfaces on both sides are respectively milled and processed into a vertebral surface with convex teeth 1. The convex teeth 1 are arranged evenly, and then two through holes 3 are opened on the plane of the body 4, the diameter of which is Φ5mm.

Embodiment 2

[0017] Example 2: In this example, pig bone bone tissue is used as the material, and it is planed and milled into a cone-shaped body 4 with a height of 20 mm, a lower bottom surface of 9 mm, an upper bottom surface of 7 mm, and a thickness of 7 mm. The groove diameter is Φ4 mm. The cross section of the groove is I-shaped. The vertebral surfaces on both sides are respectively milled and processed into vertebral surfaces with convex teeth 1. The convex teeth 1 are arranged uniformly, and then two through holes 3 are opened on the plane of the body 4, the diameter of which is Φ3mm.

[0018] The resulting lumbar intervertebral fixed fusion device of the present invention has been trial-produced and tested and proved to have good overall effects, reliable quality, safety and practicality, and remarkable curative effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com