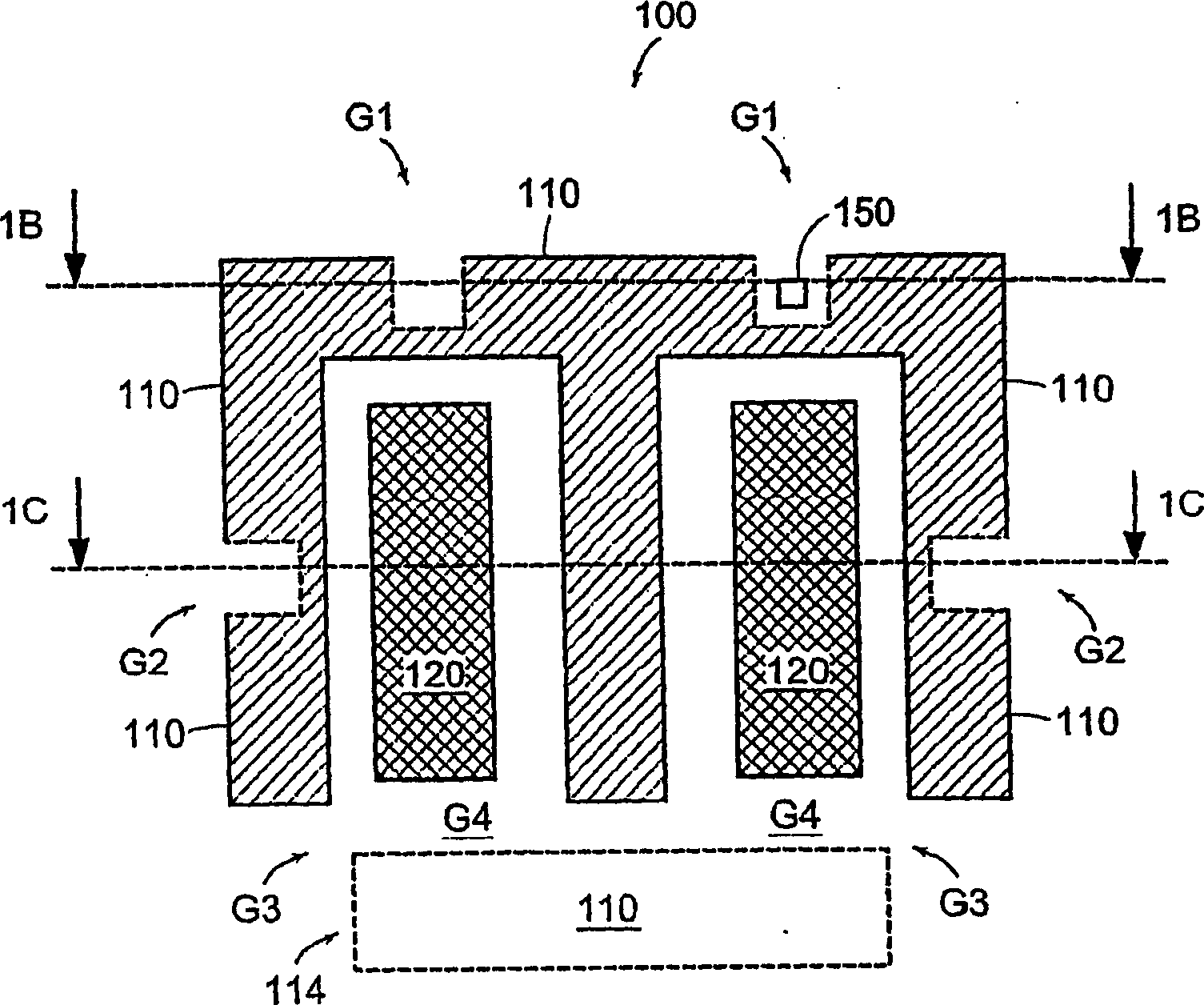

Flow control valve with magnetic field sensor

A technology of magnetic flux sensor and magnetic field generator, applied in flow control, non-electric variable control, magnetic variable adjustment, etc., can solve the problem of increasing the cost of flow control equipment, and achieve the effect of alleviating hysteresis and other factors and alleviating the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

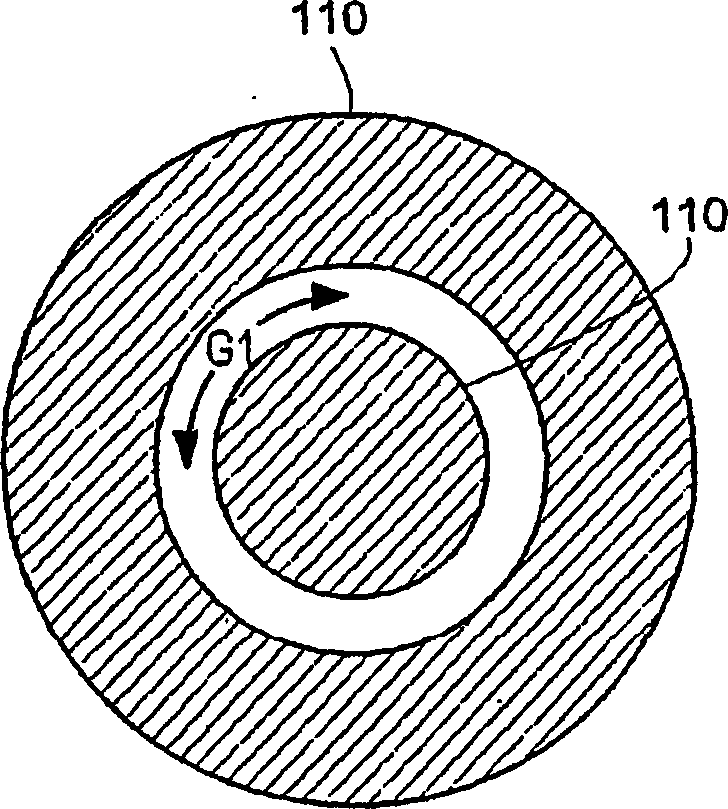

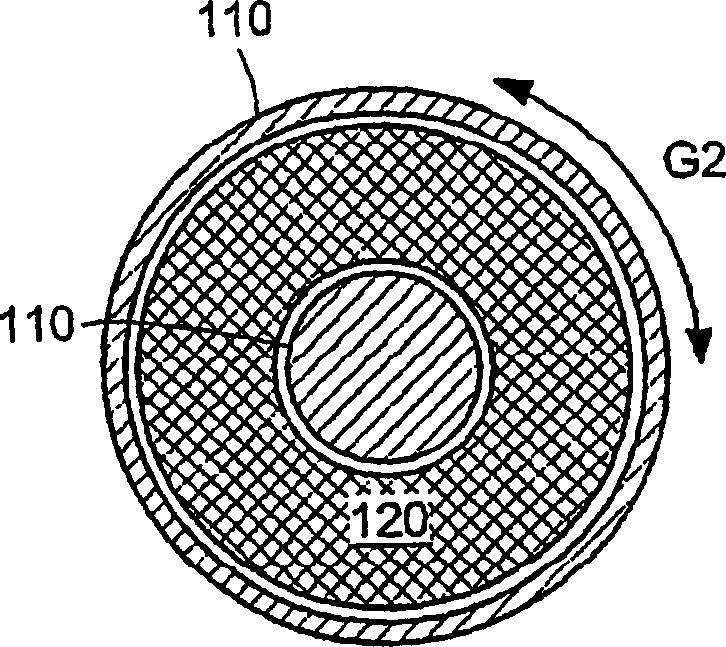

[0029] The word "hysteresis" here means the hysteresis of the magnetization value in a magnetic material due to changing the magnetizing force.

[0030] The word "residue" here means the magnetic induction remaining in a magnetized substance that is no longer under the influence of an external magnetic field. For example, the ferromagnetic plunger of a solenoid may exhibit residual magnetization when no current is applied to the solenoid.

[0031] The word "reluctance" here means the resistance to magnetic flux in a reluctance magnetic circuit and can be defined as the ratio of the magnetic potential difference to the corresponding magnetic flux. The reluctance part of a flux circuit is similar to the resistive part of a current circuit.

[0032] As used herein, "ferromagnetic material" means a material that concentrates magnetic flux by a factor greater than about 10. The relative permeability of ferromagnetic materials can be as high as about 1,000,000 as a ratio to the va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com