Dry type vibratory high-gradient magnetic separator

A high-gradient magnetic separator and vibration motor technology, applied in the fields of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of increasing energy consumption, investment and management costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

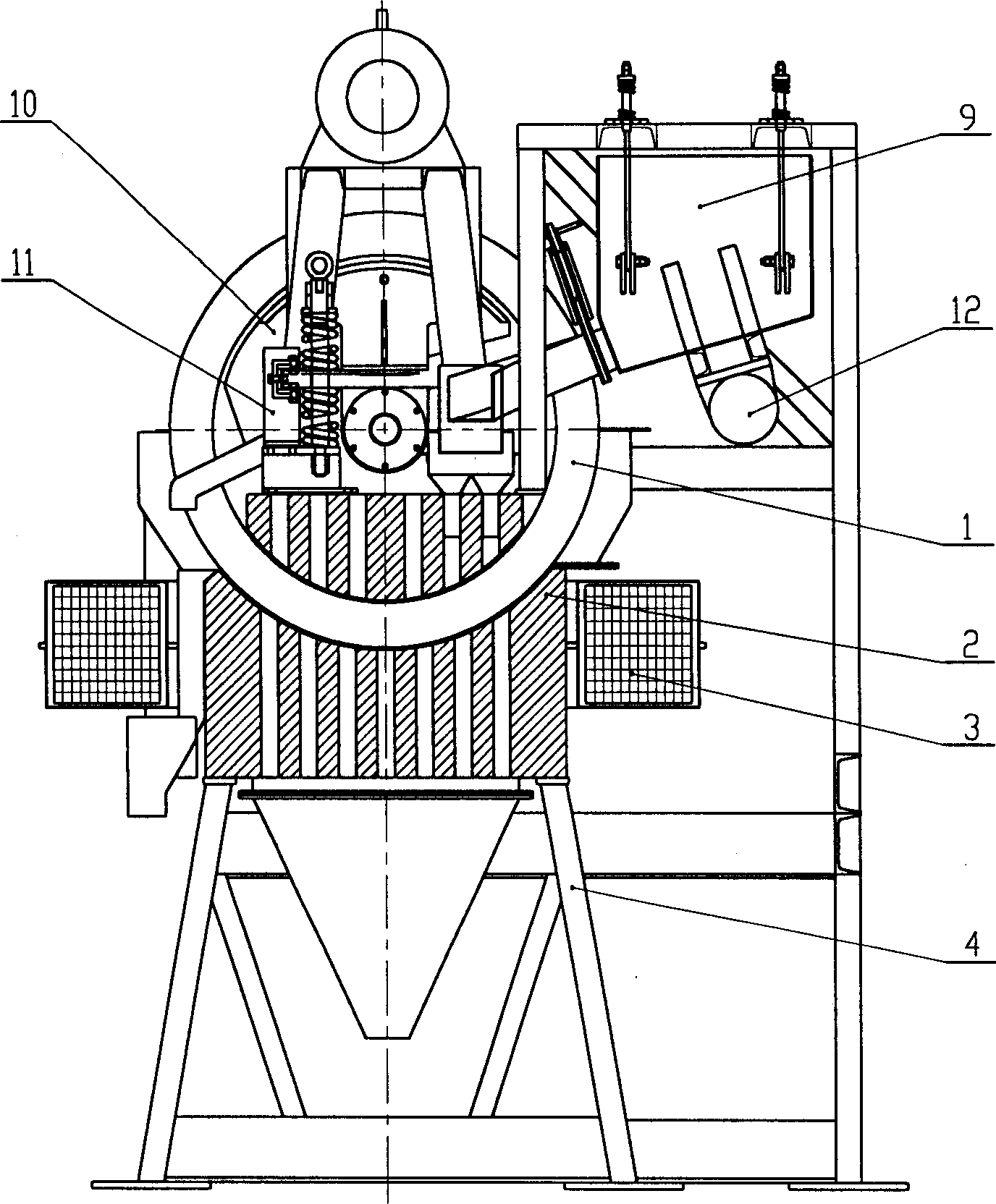

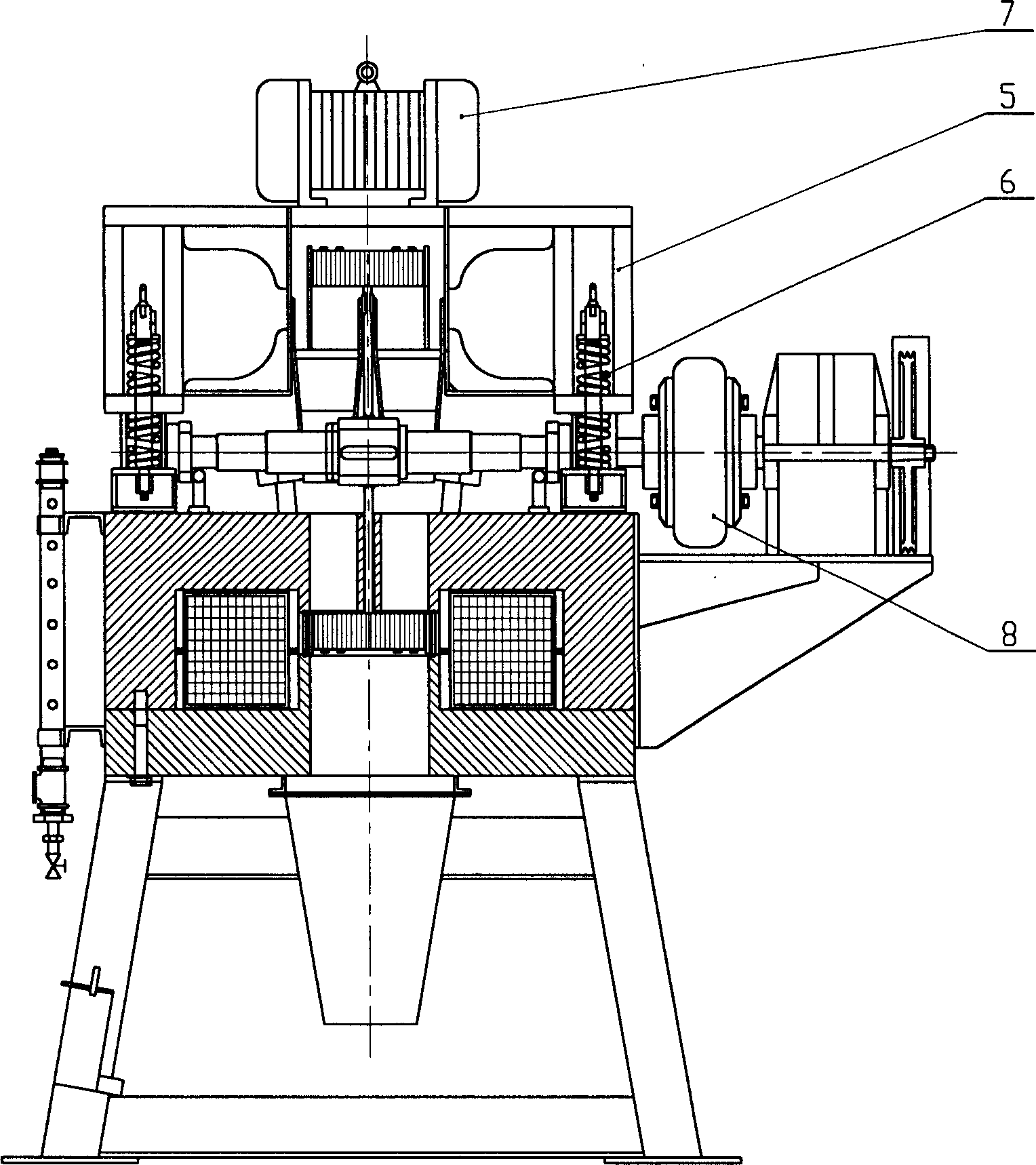

[0021] refer to figure 1 , 2 , the present invention mainly consists of a swivel 1, a yoke 2, an excitation coil 3, a frame 4, a vibrating motor frame 5, a vibrating mechanism 6, a swivel vibrating motor 7, a tire coupling 8, a feeding system 9, and a magnetic bucket 10. It is composed of a limit mechanism 11 and a vibrating motor 12 for the ore hopper.

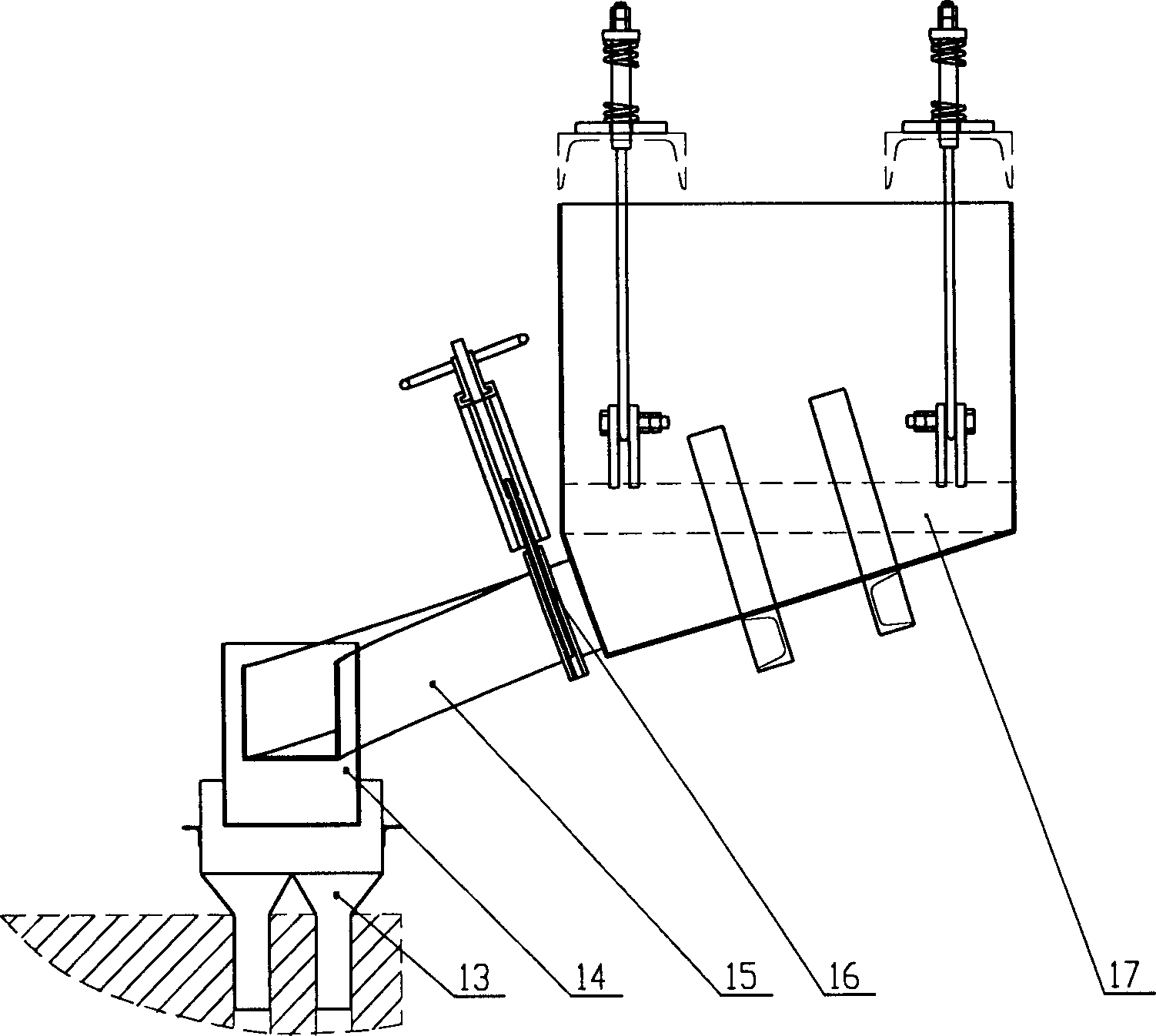

[0022] refer to image 3 , The feeding system 9 is composed of a feeding hopper 13, a feeding box 14, a feeding chute 15, a gate valve 16, and a vibration feeding box 17. Vibration feeds mine box 17 and is suspended on 4 damping springs through 4 bars, and vibration feeds mine box 17 bottoms and is equipped with feed bucket vibrating motor 12. The usual wet magnetic separator uses water as the medium, and the minerals are dissolved in the water to form a slurry that enters the separation area. In the present invention, under the action of the vibrating motor 12 of the ore hopper, after the dry ore enters the feeding syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com