Apparatus for measuring quality of laser beam

A laser beam quality and measurement device technology, applied in the laser field, can solve problems such as the difficulty in measuring the quality of high-energy laser beams and the inability to measure pulsed laser beams instantaneously

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] specific implementation

[0065] Below by embodiment the present invention will be further described, but should not limit protection scope of the present invention with this.

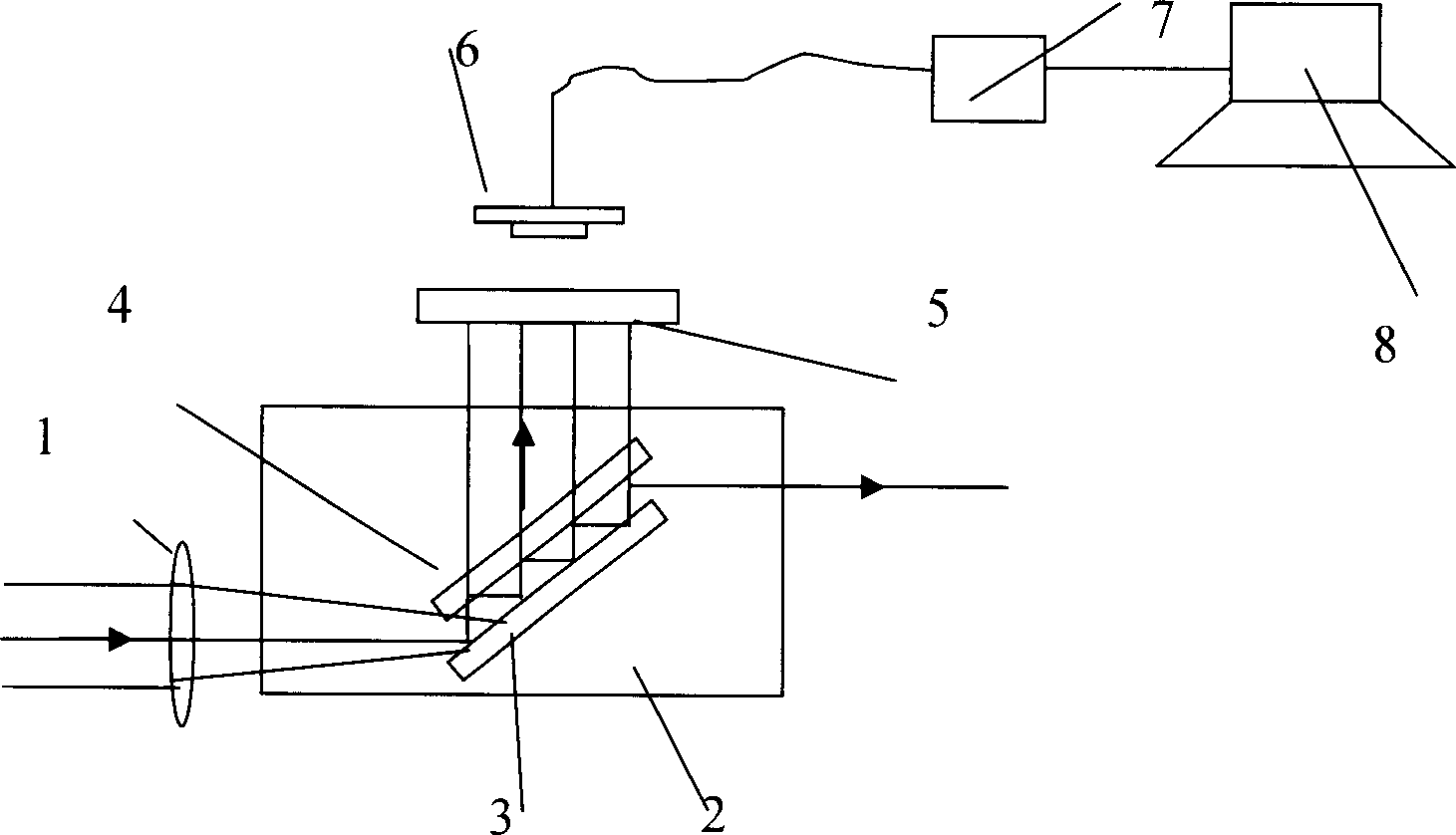

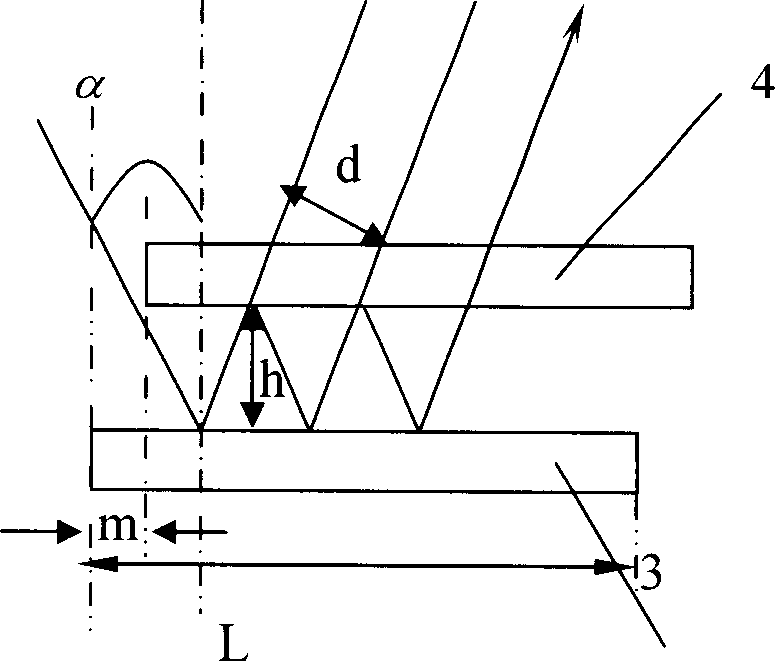

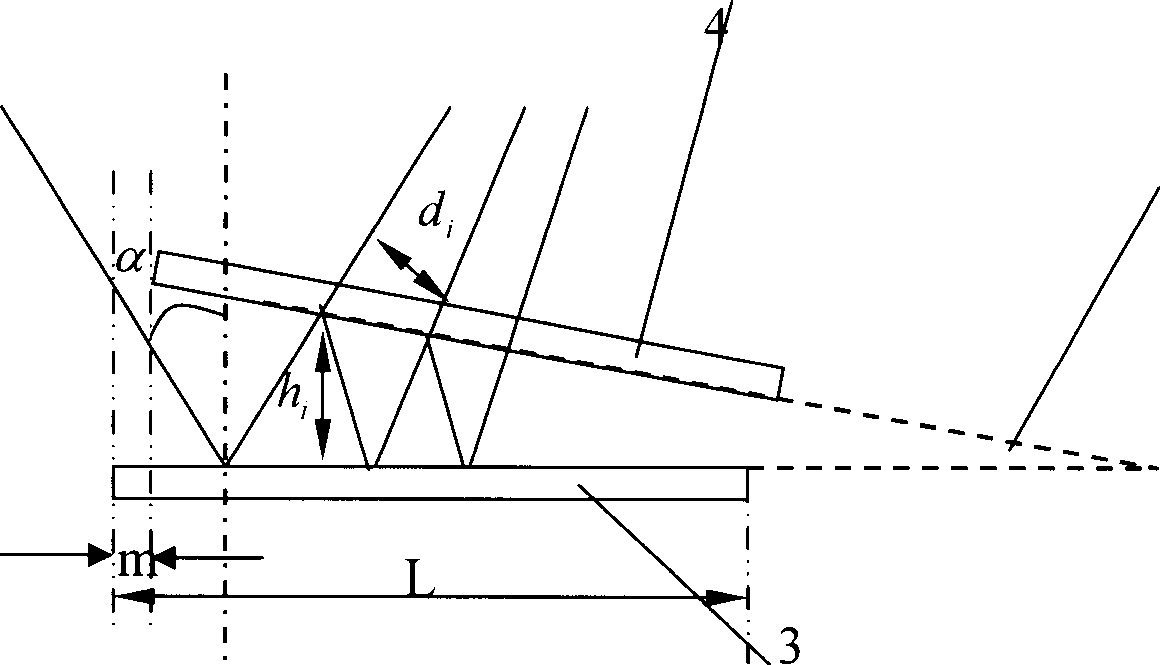

[0066] see first figure 1 As can be seen from the figure, the laser beam quality measuring device of the present invention comprises a focusing lens 1, an attenuation sheet 5, a CCD6 for collecting light spots and a computer 8 with a high-speed acquisition card 7, and its feature is that the attenuation sheet 5 is a diffuse scattering There is a light splitting device 2 between the focusing lens 1 and the diffuse scattering plate 5, the light splitting device 2 is composed of a first flat plate 3 and a second flat plate 4 placed in the optical path at 45° to the optical path, the first flat plate 3 There is a dislocation m with the second flat plate 4, wherein the reflectivity of the inner surface of the first flat plate 3 is 100%, the value range of the reflectivity of the inner surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com