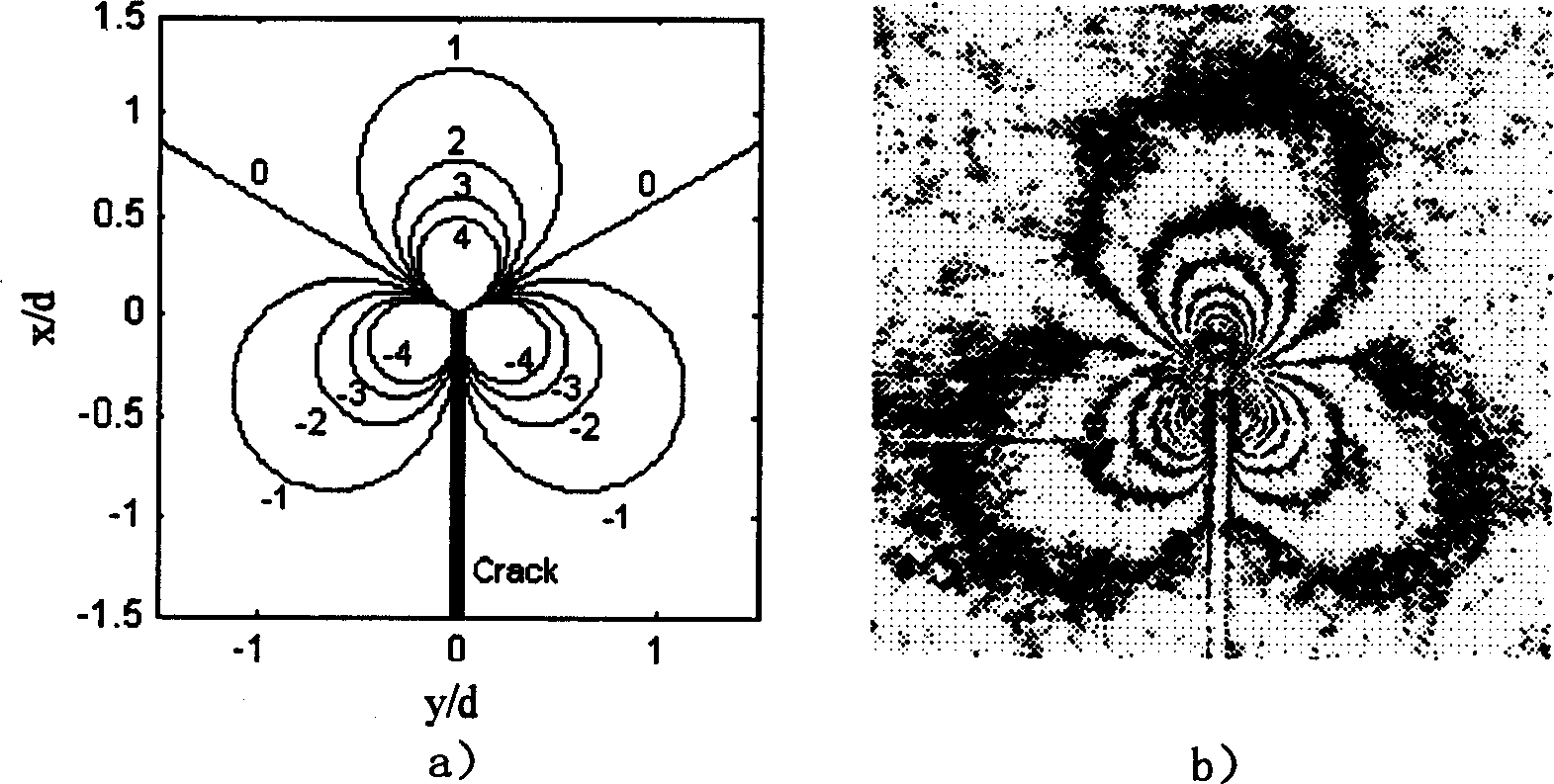

Method and apparatus for extracting order value of coherent gradient sensing interference fringe

A coherent gradient sensitive and interference fringe technology, which is applied in the field of fracture mechanics parameter measurement, can solve problems such as errors, thick interference fringes, and irregular shapes, and achieve the effects of improving accuracy, improving calculation accuracy, and reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

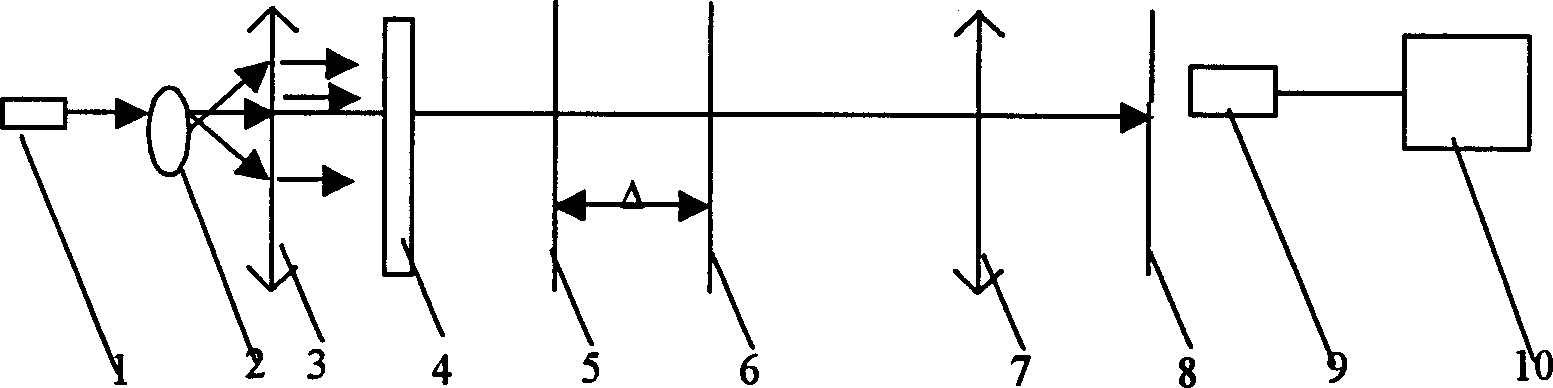

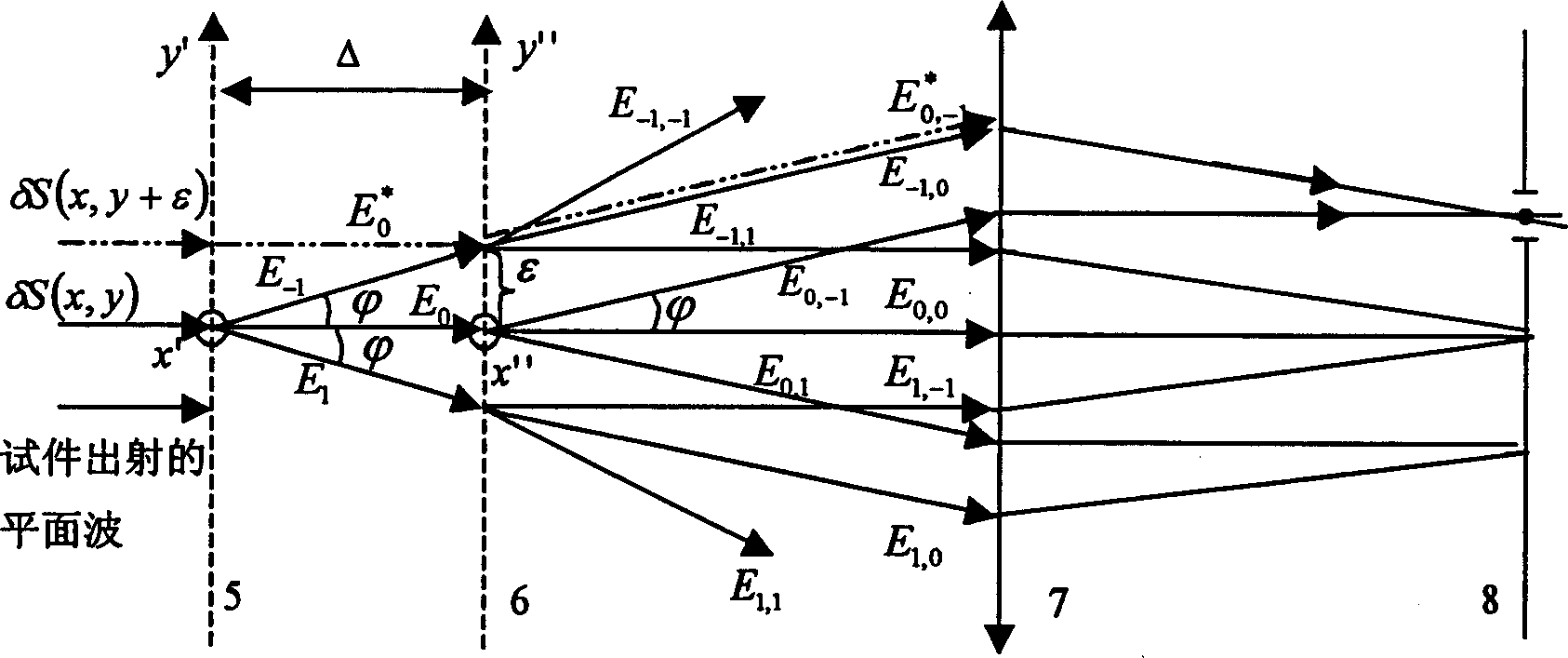

Embodiment Construction

[0027] The method for extracting the series of coherent gradient-sensitive interference fringes proposed by the present invention first expands a beam of laser light to obtain divergent light, then becomes parallel light through a convex lens, and is incident on the surface of the test piece; the parallel light beam emitted from the test piece is divided into Two rays, the distance between the first ray and ray is Δ 1 The first grating and the second grating produce coherent gradient-sensitive interference fringes, and the second light passes through with a distance of Δ 2 The third grating and the fourth grating generate coherent gradient-sensitive interference fringes; image the two interference fringe fields and take pictures of the interference fringe fields; The background light intensity of the interference fringe pattern is a 1 、a 2 Apply load to this test piece, take the coherent gradient sensitive interference fringe figure of loading test piece from two optical pat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com