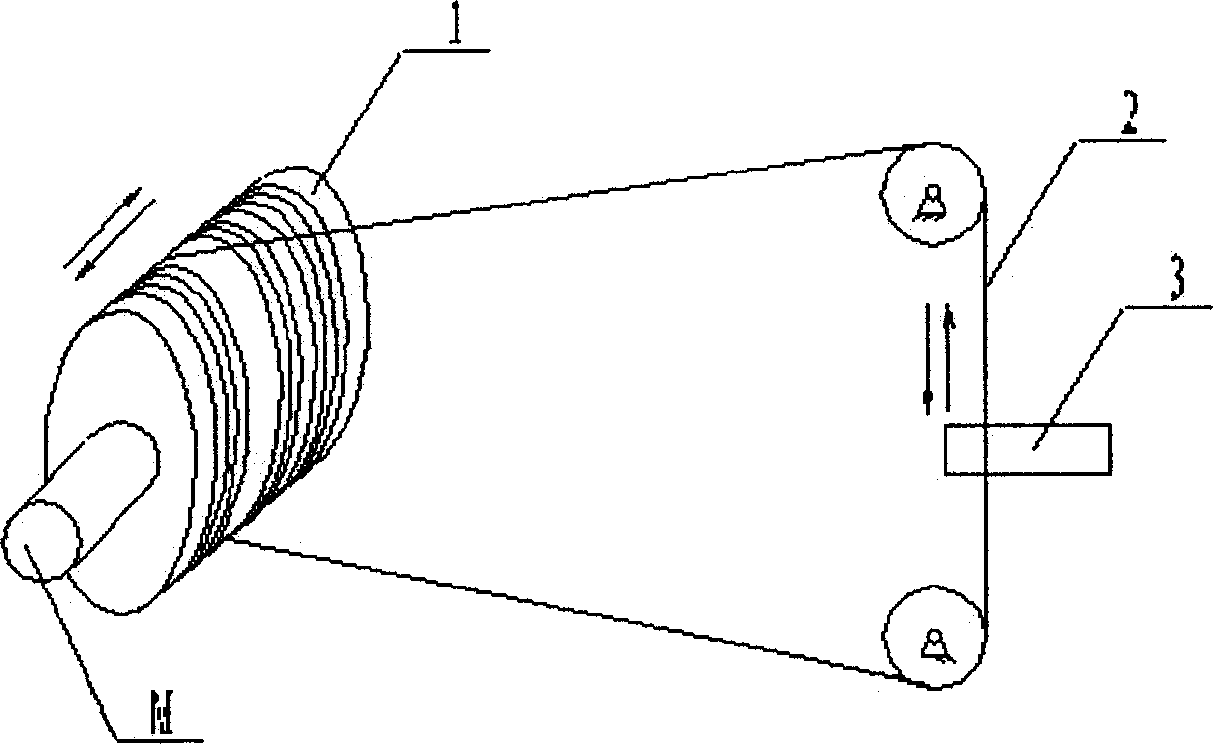

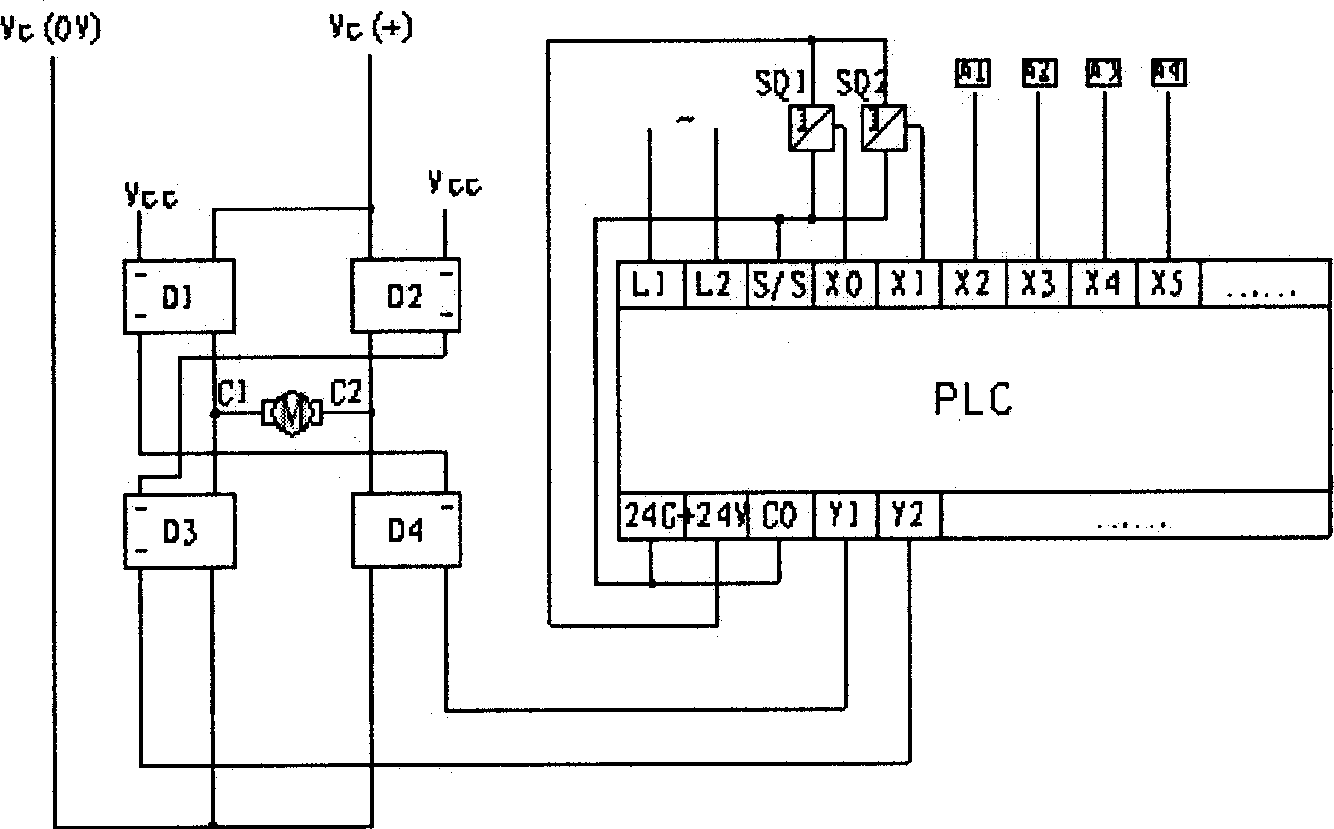

Short range cutting method of wire quick-moving type electrospark wire-electrode cutting machine tool and device

A cutting machine tool and wire electric discharge technology, applied in the field of wire electric discharge machine tools, can solve problems such as easy wire breakage, unsatisfactory processing effect, and easy wear and tear of electrode wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016]Embodiments of the present invention: the short-range cutting method of the fast wire electric discharge machine tool of the present invention can be directly implemented on the existing fast wire cutting machine tool. Make the wire drum motor of the fast-feeding wire cutting machine energized to drive the wire drum to rotate forward t 1 Time, so that the wire drum drives the electrode wire to cut the processed part along the positive direction t 1 time, and then de-energize the wire drum motor t 2 After a certain time, the wire drum motor is energized to drive the wire drum to rotate in reverse t 3 Time, so that the wire drum drives the electrode wire to cut the processed parts in the opposite direction t 3 After a certain time, turn off the wire drum motor 2 After a certain time, the wire drum motor is energized again to drive the wire drum to rotate forward t 1 Time, so that the wire drum drives the electrode wire and cuts the processed parts along the positive di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com