Artistic ornament strip production process

A production process and decorative strip technology, which is applied in the fields of crafts, decorative arts, and architecture for producing decorative surface effects, and can solve problems such as inconvenient installation and positioning, environmental protection, and adverse health effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

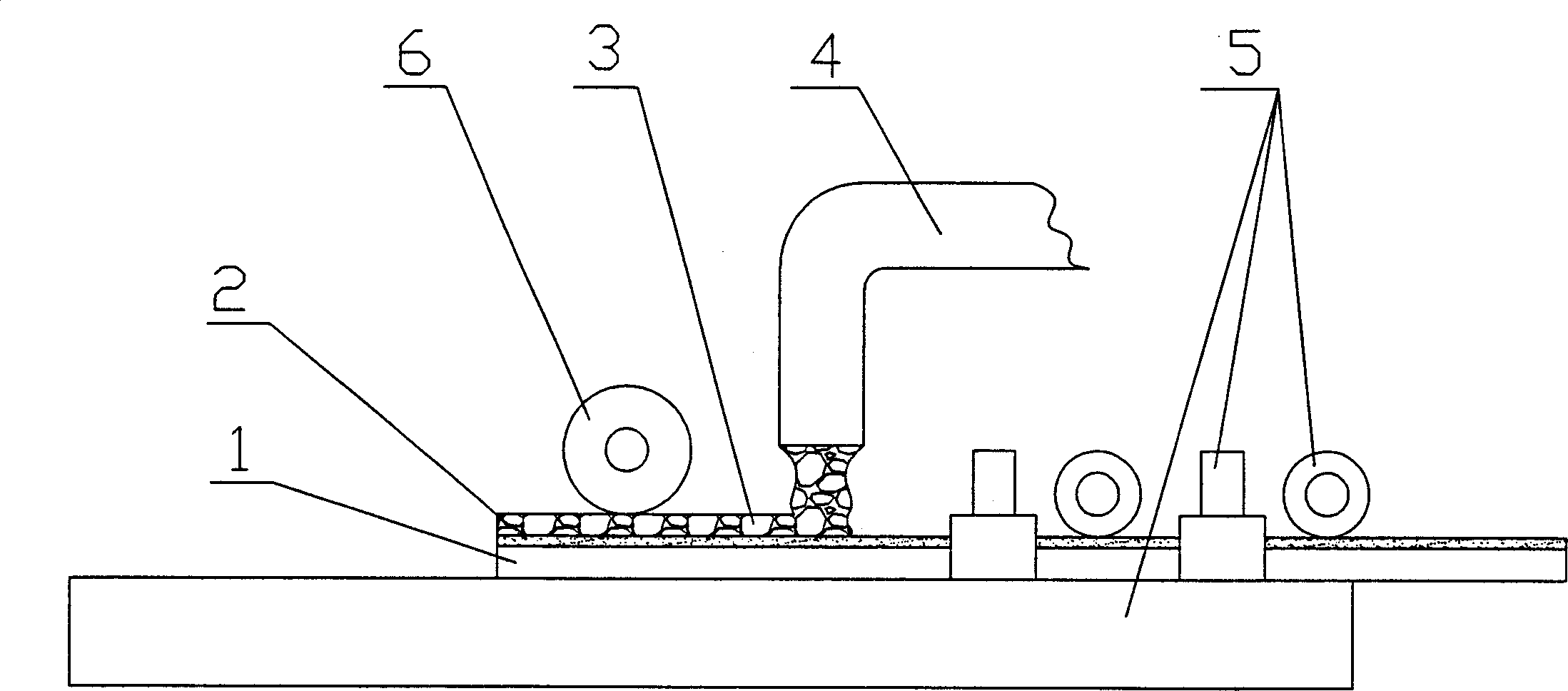

[0011] A kind of artistic decorative strip production process of the present invention comprises prefabricated decorative strip wooden embryo process, is characterized in that: subsequent steps are:

[0012] (1) coat the primer layer 2 on the decorative surface of the prefabricated decorative strip wood embryo body 1;

[0013] (2) Use sand and glue as the main raw materials to make decorative covering fabric 3;

[0014] (3) Firstly, the decorative covering fabric 3 is arranged on the decorative surface of the decorative strip wood embryo body 1 advancing along the printing machine frame 5 through the injection pipe 4 of the printing machine, and then the printing runner 6 of the printing machine rolls the decoration Cover the fabric so that the surface of the decorative covering fabric 3 forms a three-dimensional decorative surface;

[0015] (4) Air-dry or air-dry the surface layer of the three-dimensional decoration.

[0016] After the three-dimensional decoration surface l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com