Oil-containing sludge fluidization and reduction process

A process technology and reduction technology, which is applied in the field of oily sludge treatment and recycling in oil fields, can solve the problems of large investment and land occupation, low economic benefits, and restrictions on popularization and application, and achieve less equipment, good economic and social Benefits, simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

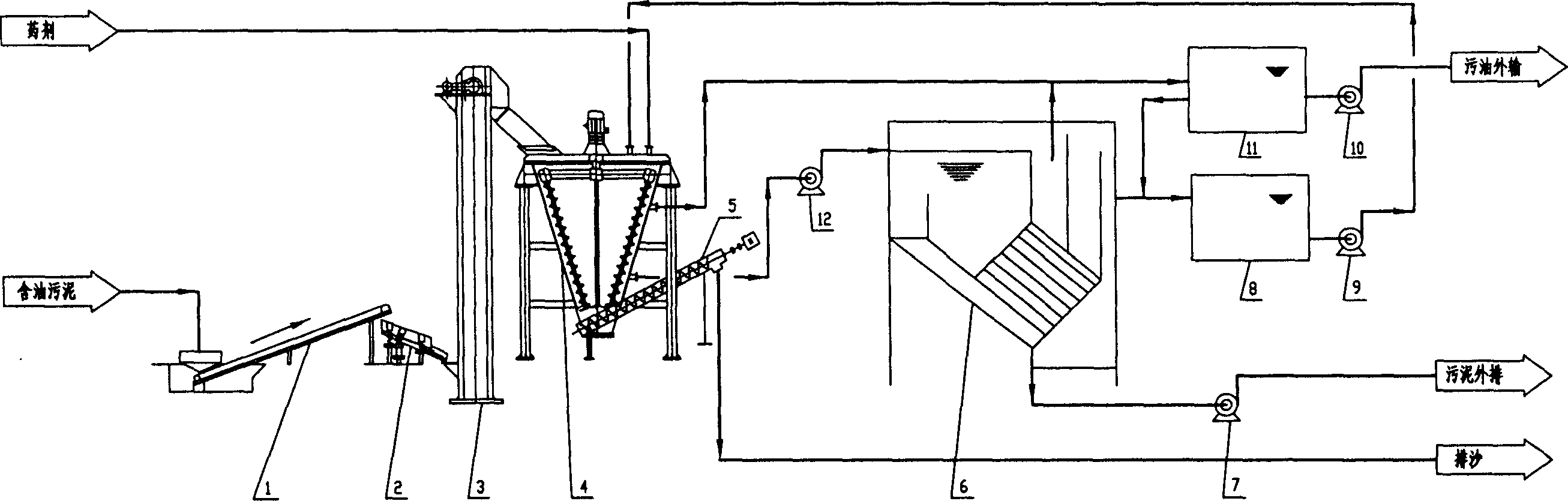

[0013] The present invention is provided by the following embodiments, which will be described below in conjunction with the accompanying drawings.

[0014] As shown in the figure, the equipment and process flow adopted by the present invention are as follows: the belt conveyor 1 transports the sludge to the vibrating screen 2, and after the larger sludge particles are screened out, they enter the sludge with the help of a bucket elevator 3. Fluidized sand washer 4, in which sewage pump 12 is used to add sewage, feed steam to heat, add medicament to stir and mix; set aside to settle; waste oil discharged from fluidized sand washer 6 is lifted to sewage by sewage pump 10 The oil tank 11 is recycled; the screw propeller 5 is used to push the mud-water mixture into the inclined plate settler 6 for sedimentation and separation again; the sewage discharged from the inclined plate settler 6 passes through the circulating water tank 8 and is lifted by the sewage pump 9 to fluidized sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com