Rectification method in acetic acid synthesis process by low-pressure methanol carbonylation

An oxo, low-pressure technology, applied in the field of rectification, can solve problems such as unreasonable utilization of rectification energy, consumption of water cycle energy, and insufficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

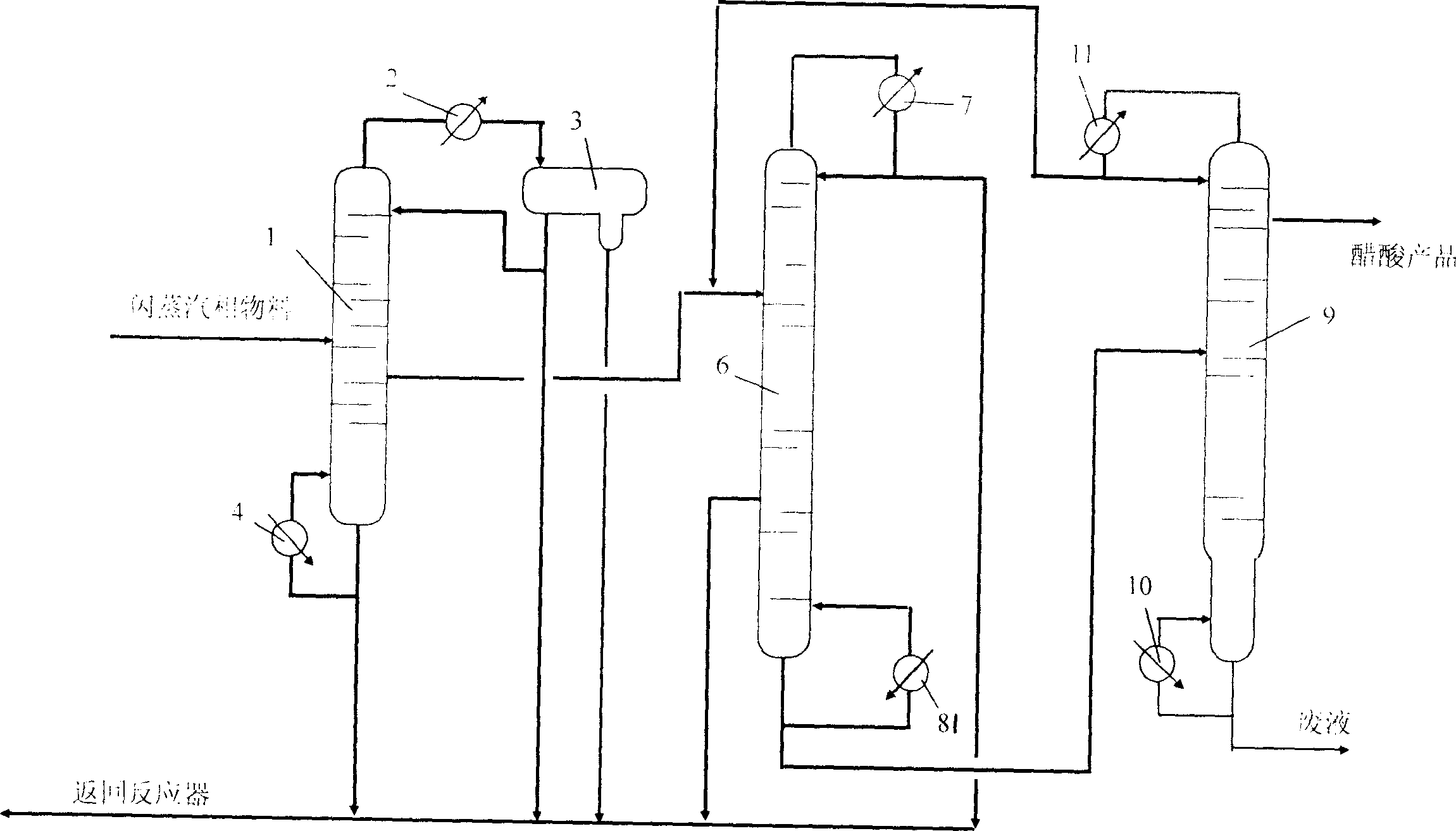

[0015] Example 1 Light removal tower, dehydration tower and finished product tower are all plate rectification towers

[0016] The vapor phase material flow rate that flasher produces is 68.81t / h, and composition (weight percent, the same below) is: non-condensable steam 1.02%, hydrogen iodide 0.06%, iodomethane 37.98%, methyl acetate 1.55%, water 11.64% , 47.62% acetic acid, 0.13% propionic acid. Light removal tower 1 top pressure 190kPa (absolute pressure, hereinafter the same), reflux ratio promptly enters the liquid flow rate (mol / h) of rectifying section and the ratio of tower top distillate flow rate (mol / h) is 2.0, light removal Column reboiler 4 adds heat 1.633Mw. The top pressure of the dehydration tower 6 is 110kPa, and the reflux ratio is 1.2. The pressure at the top of the product column 9 is 250kPa, the reflux ratio is 3.0, and the heat added to the reboiler 10 of the product column is 12.903Mw. The liquid in the dehydration tower 6 and the top steam in the pro...

Embodiment 2

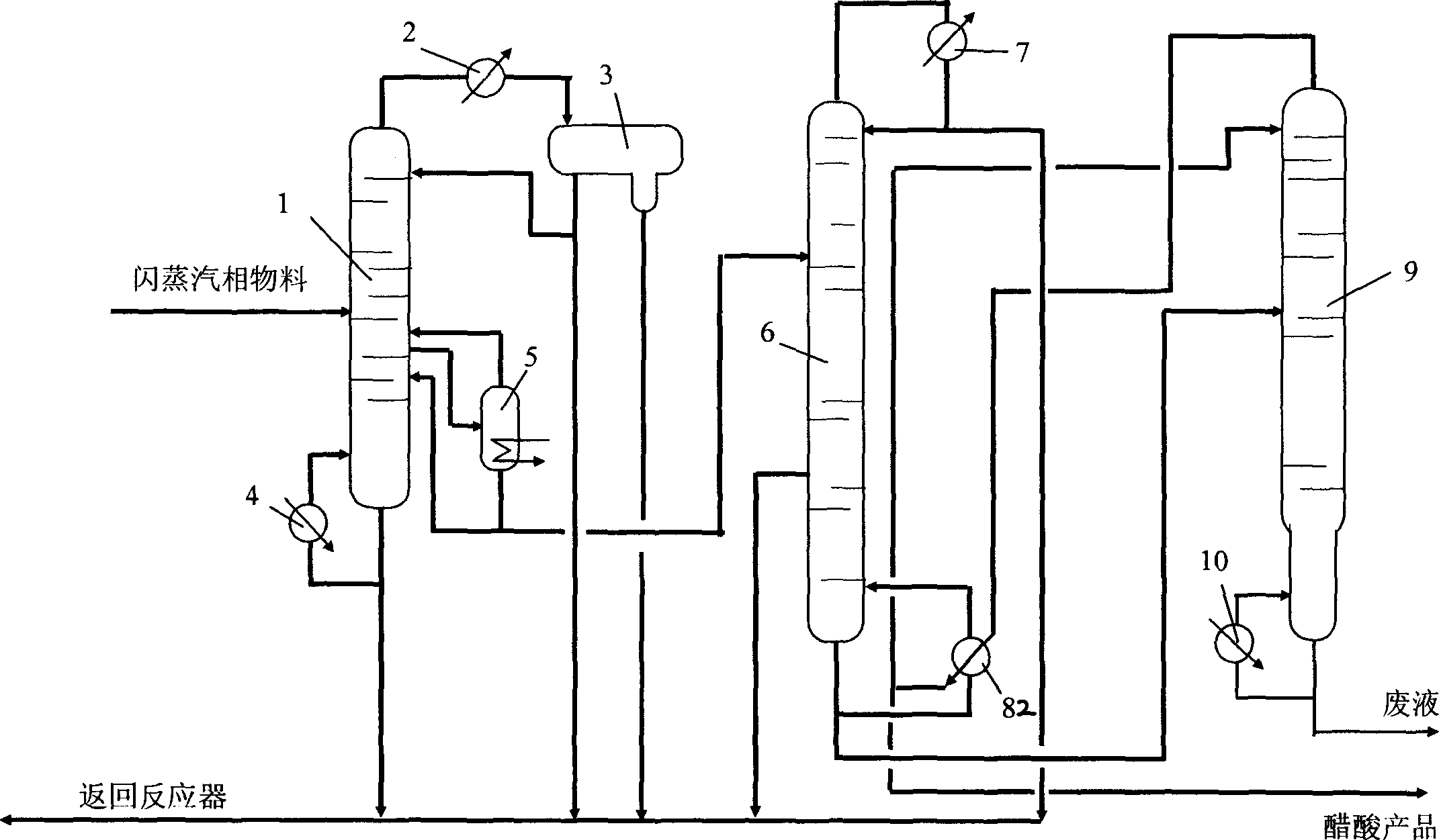

[0020] Example 2 Light removal tower, dehydration tower and finished product tower are all porcelain corrugated packing towers

[0021] The flow rate of the vapor phase material produced by the flasher is 6.525t / h, and the composition is: 0.98% of non-condensable steam, 0.04% of hydrogen iodide, 37.38% of methyl iodide, 1.61% of methyl acetate, 11.97% of water, 47.9% of acetic acid, propionic acid 0.12%. The top pressure of light removal tower 1 is 190kPa, the reflux ratio is 2.0, and the heat added to reboiler 4 of light removal tower is 0.06Mw. The top pressure of the dehydration tower 6 is 110kPa, and the reflux ratio is 1.4. The pressure at the top of the product column 9 is 200kPa, the reflux ratio is 2.8, and the heat added to the reboiler 10 of the product column is 1.30Mw. The bottom liquid of dehydration tower 6 and the top steam of finished product tower 9 are heat-exchanged in the reboiler-condenser 82, and the liquid of dehydration tower 6 is boiled in the reboil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com