Oil elastic modulus detector based on volume elastic modulus definition

A bulk elastic modulus, elastic modulus technology, applied in measuring devices, using stable tension/pressure to test material strength, using mechanical devices, etc., can solve the problem of difficult pressure wave velocity accurate measurement, high cost and complex system. and other problems, to achieve accurate and reliable measurement results, high degree of automation, and good detection results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with drawings and embodiments.

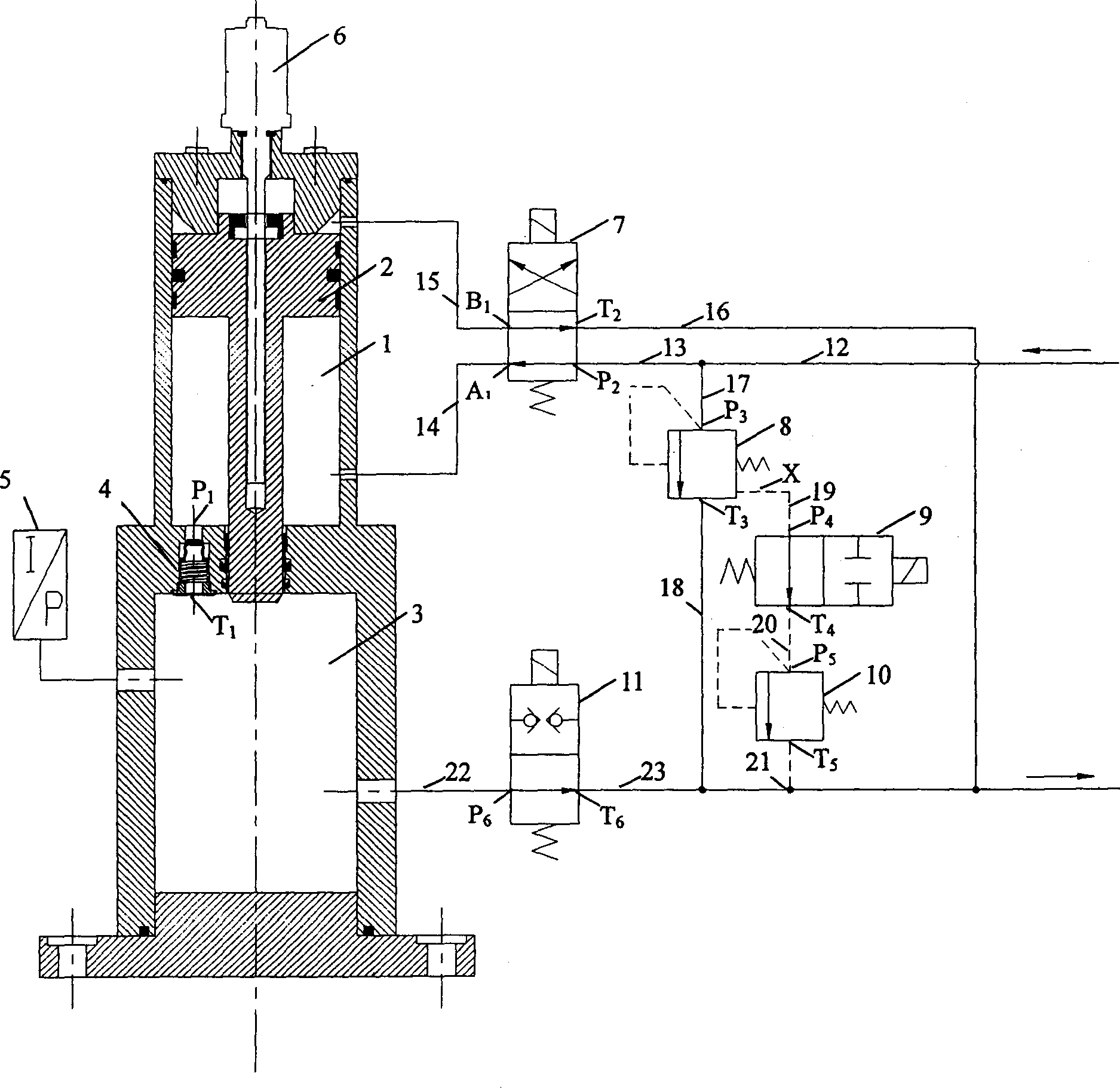

[0020] As shown in the drawings, the present invention includes: loading cylinder 1, piston and piston rod 2, test chamber 3, check valve 4, pressure sensor 5, built-in displacement sensor 6; The piston rod extends into the test chamber 3 and can move axially in the test chamber 3. The oil inlet P of the check valve 4 1 It communicates with the rod cavity of loading cylinder 1, and the oil outlet T of check valve 4 1 It communicates with the test chamber 3, the pressure sensor 5 communicates with the test chamber 3, the built-in displacement sensor 6 is placed in the piston and the piston rod 2 of the loading cylinder 1, the rodless chamber and the rod chamber of the loading cylinder 1 and the test chamber 3 pass through the tube The roads are respectively connected with the hydraulic system.

[0021] The hydraulic system includes: two-position four-way electromagneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com