Technology for predicting and controlling surface roughness of finished plate for planishing mill

A control technology and roughness technology, applied in the direction of adaptive control, material size control, general control system, etc., can solve problems such as not found

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

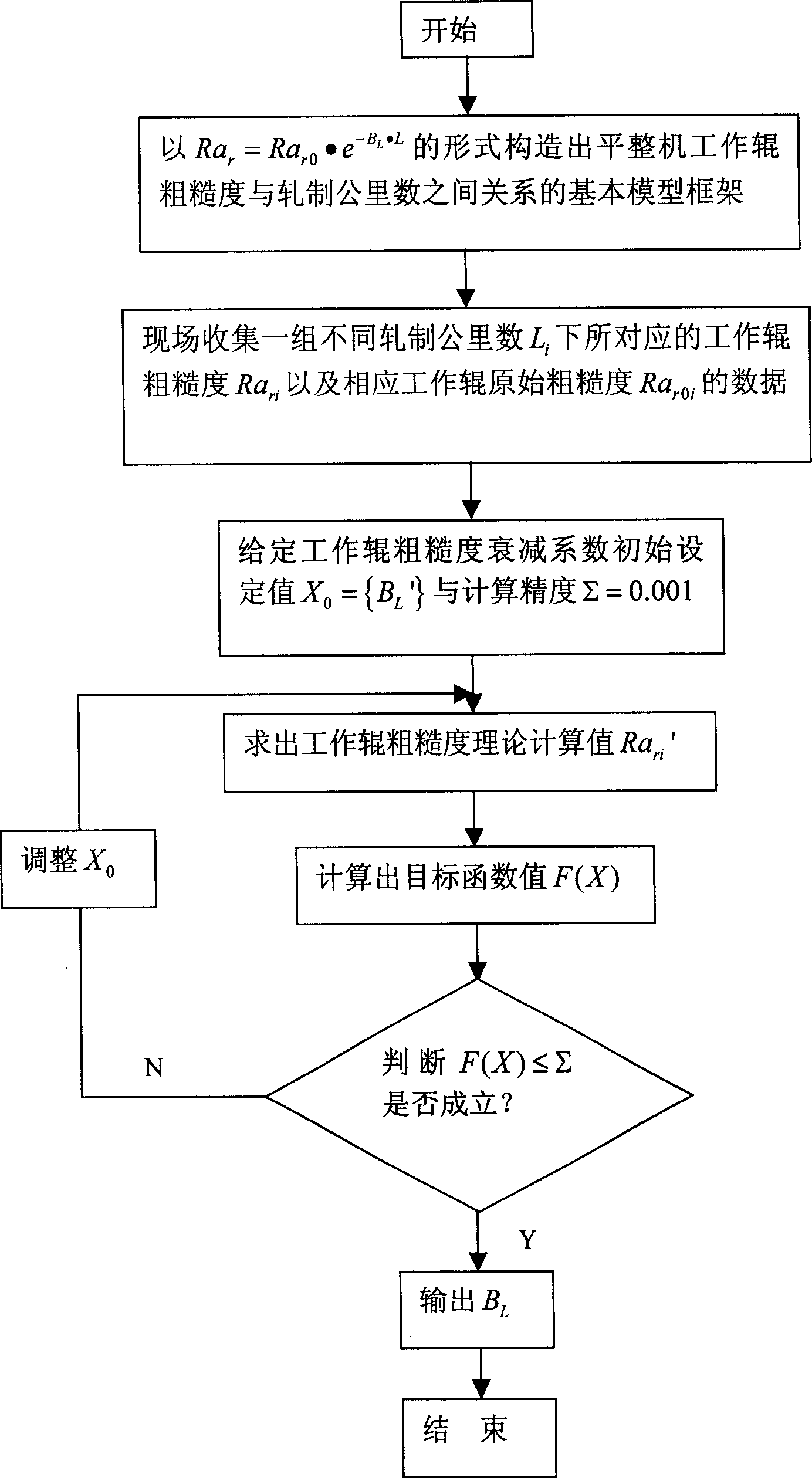

Method used

Image

Examples

Embodiment 1

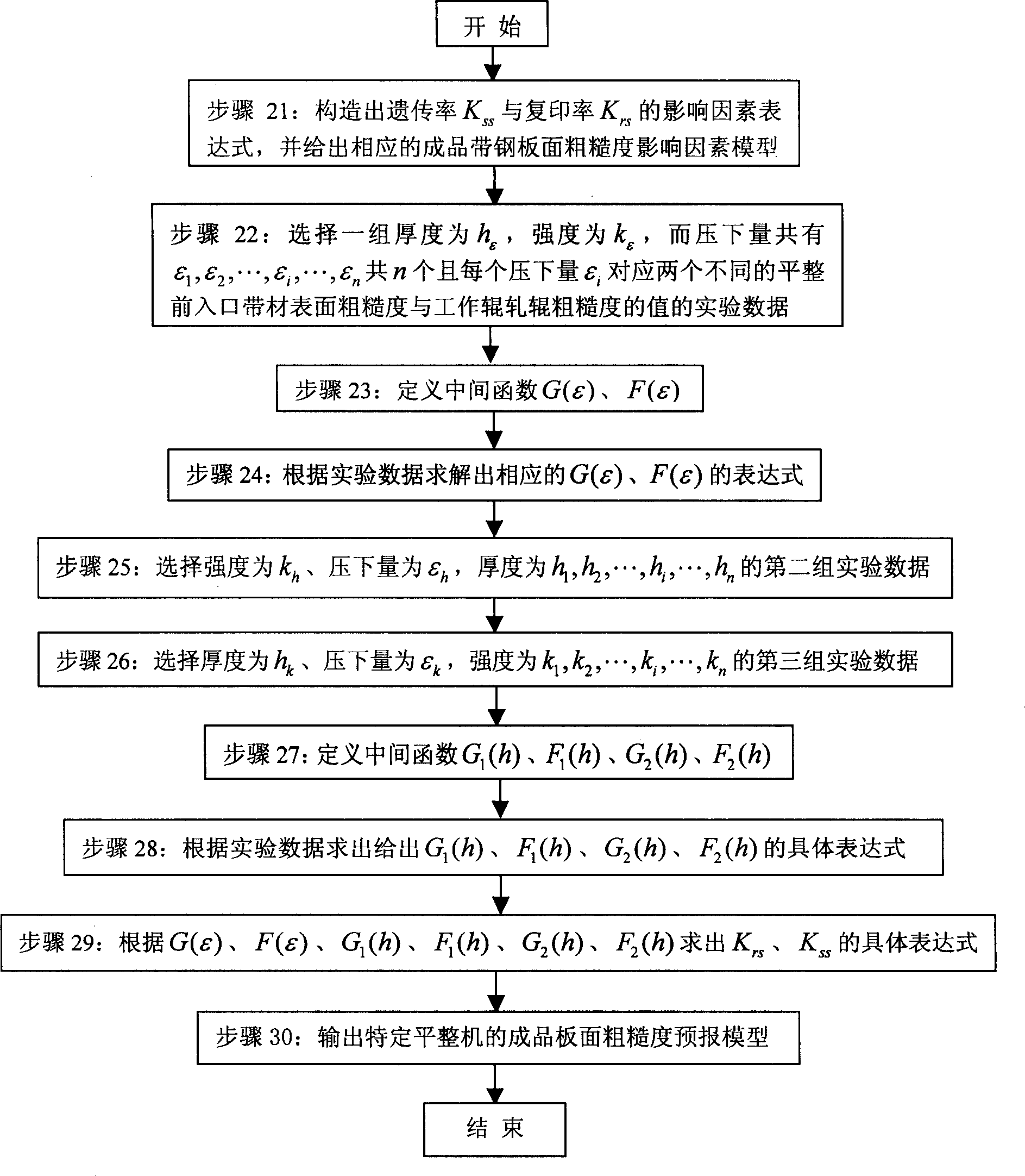

[0081] According to rolling theory and field experience, it can be known that for the temper rolling process, the surface roughness of the finished strip is mainly superimposed by the roughness copied from the work roll to the strip and the genetic part of the strip roughness before tempering made. Among them, the roughness of the work roll copied to the strip surface is related to the roughness of the work roll itself and the impression rate (that is, the ability of the roll roughness to be transferred to the strip); the roughness of the inherited part of the strip before leveling is taken from The original roughness of the strip before leveling and the corresponding heritability. It can be seen that to realize the on-line prediction of roughness, it is very critical to obtain the expression of imprinting rate and heredity rate, and the present invention adopts the following formula to express the surface roughness of finished strip steel after smoothing:

[0082] Ra strip ...

Embodiment 2

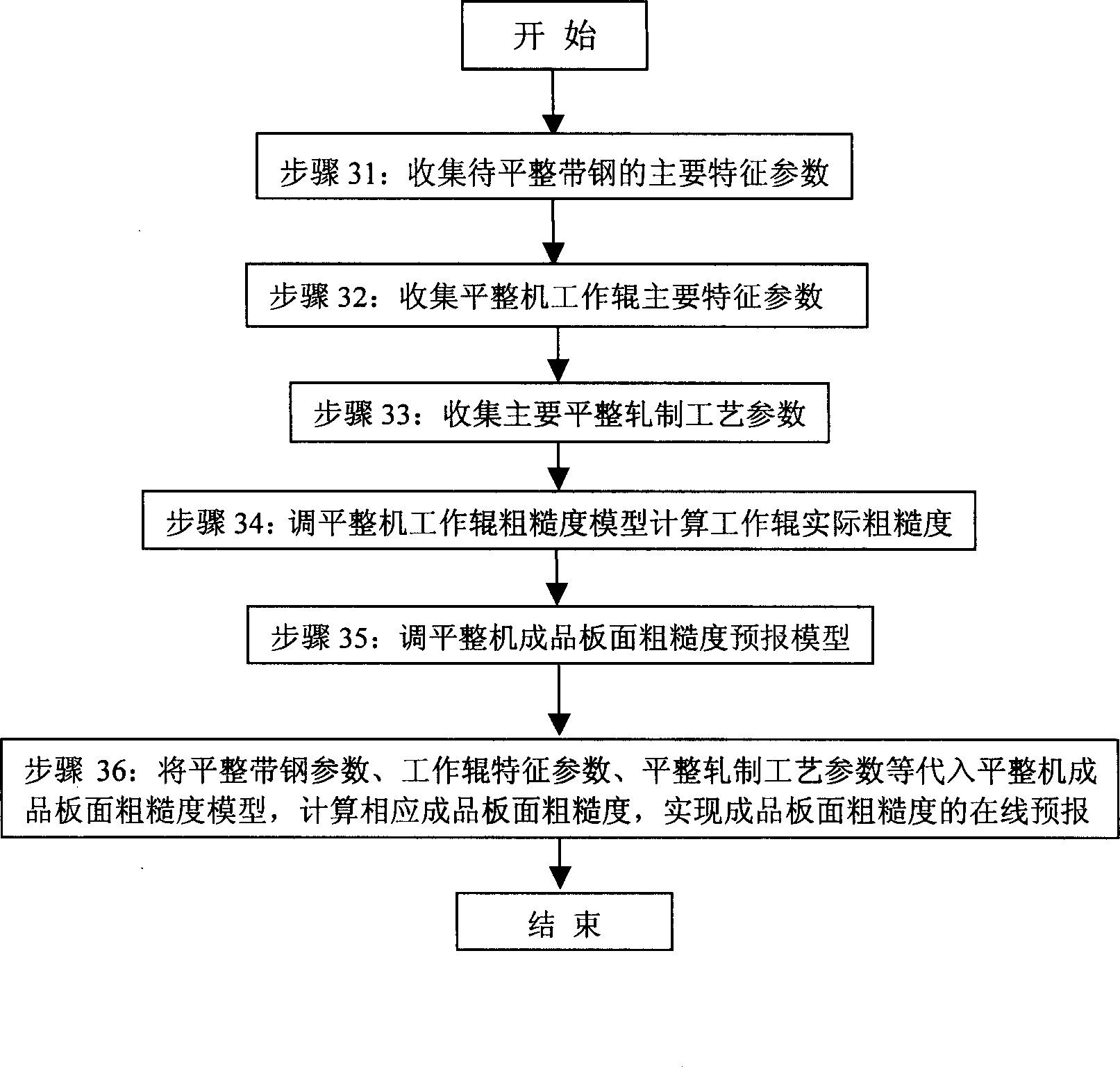

[0125] 一般而言,对于特定平整机而言,建立成品板面粗糙度模型的目的之一是为了实现根据已知轧制工艺参数对成品的板面粗糙度进行在线预报。

[0126] image 3 是按照本发明一个较佳实施例的平整机成品板面粗糙度在线预报计算流程图。 该实施例被用于特定平整机成品板面粗糙度的在线预报,并且关于该平整机在平整前入口带材表面粗糙度与工作辊原始粗糙度及换辊后的轧制公里数已 Know.

[0127] 首先,在步骤31中,收集待平整带钢的主要特征参数,包括带钢的厚度h、强度k、原始表面粗糙度Ra ge Wait.

[0128] 随后,在步骤32中,收集平整机工作辊主要特征参数包括原始粗糙度Ra r0 与轧制公里数L。

[0129] 接着,在步骤33中,收集主要平整轧制工艺参数,主要是指平整的延伸率。

[0130] 随后,在步骤34中,调用相应的工作辊粗糙度模型,利用下式求出相应的工作辊表面粗糙度:

[0131] Ra r = Ra r 0 · e - B L · L - - - ( 58 )

[0132] 式(58)中,Ra r 为平整机工作辊表面粗糙度,Ra r0 为平整机工作辊原始粗糙度,L为工作辊换辊后的轧制公里数,B L 为工作辊粗糙度衰减系数。

[0133] 接着,在步骤35中,调平整机成品板面粗糙度预报模型。

[0134] 最后,在步骤36中,将平整带钢参数、工作辊特征参数、平整轧制工艺参数等代入平整机成品板面粗糙度模型,计...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com