Electromagnetic oven with turbo fan

A technology of turbo fan and induction cooker, which is applied in the field of induction cooker, can solve the problems of low efficiency and waste, and achieve the effect of good heat dissipation system, less turbulent flow and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

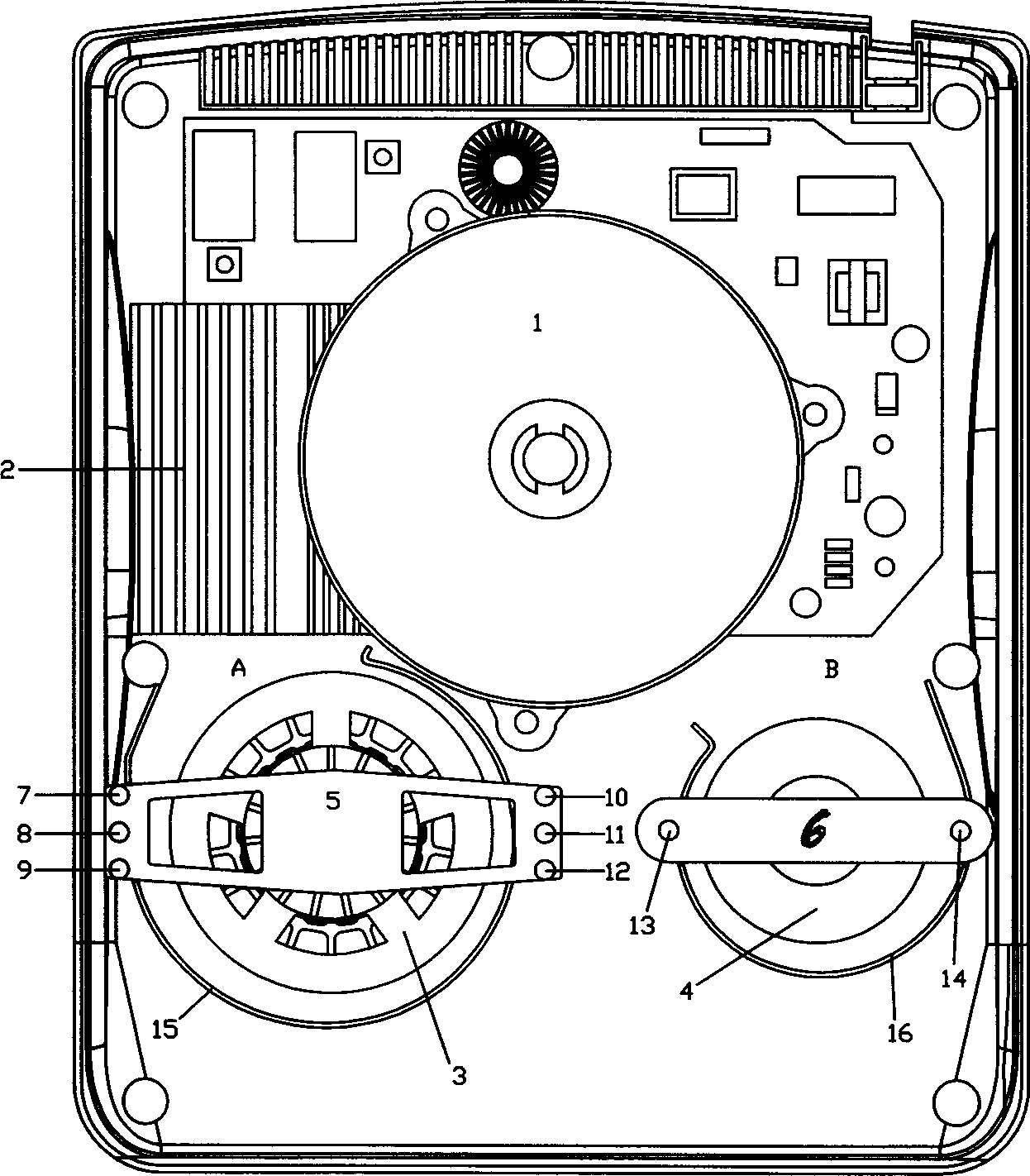

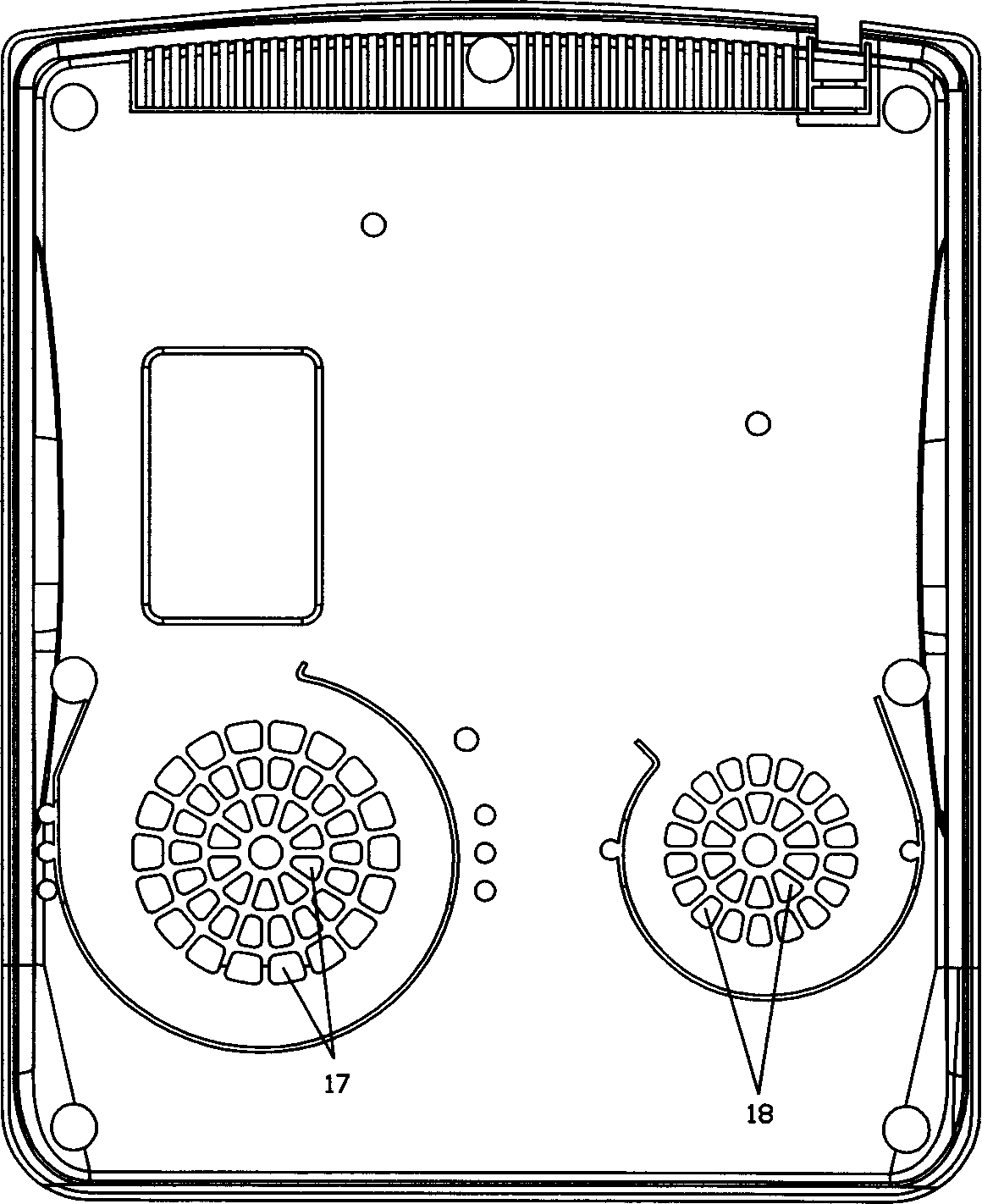

[0023] When implementing, refer to figure 1 As shown, according to the needs of the induction cooker model, it is equipped with a suitable turbo fan. When the bottom shell of the induction cooker is opened, the fixed position, air inlet and wind shielding position of the turbo fan are designed and injection molded together. Press the snail shell frame of the built-in turbo fan with the fan bracket and fix it on the pillar with screws. The air outlet of the large turbo fan is aligned with the heat sink, and the air outlet of the small turbo fan is aligned with resistors, capacitors, transistors, transformers and coil disks. After each electronic component is properly installed, the microcrystalline plate is covered, and the present invention is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com