Mechanism for steel cylinder overturning stand

A technology of steel cylinders and reversing cylinders, which is applied to conveyor objects, transportation and packaging, roller tracks, etc., to achieve the effects of convenient transportation, high degree of automation, and low manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

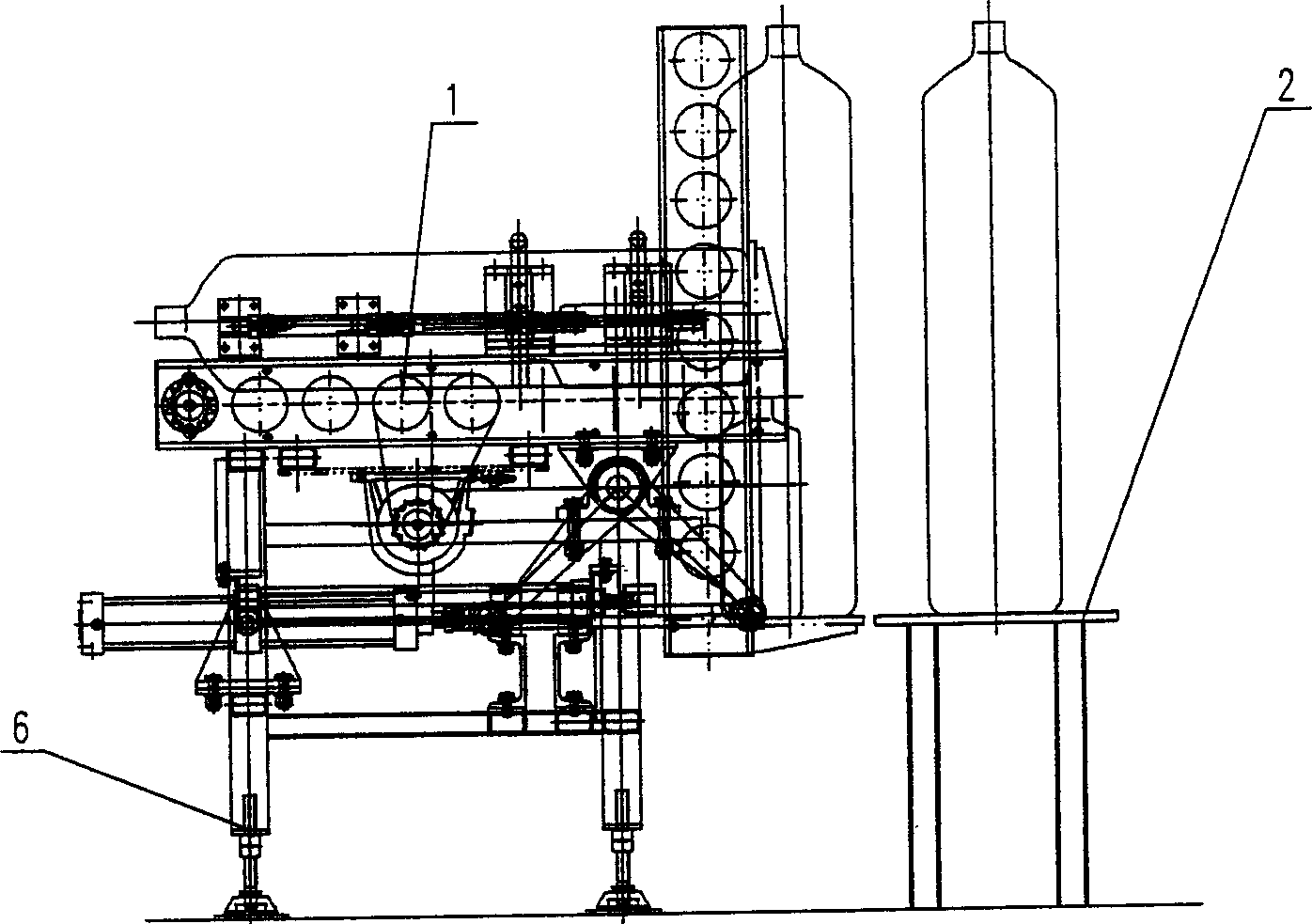

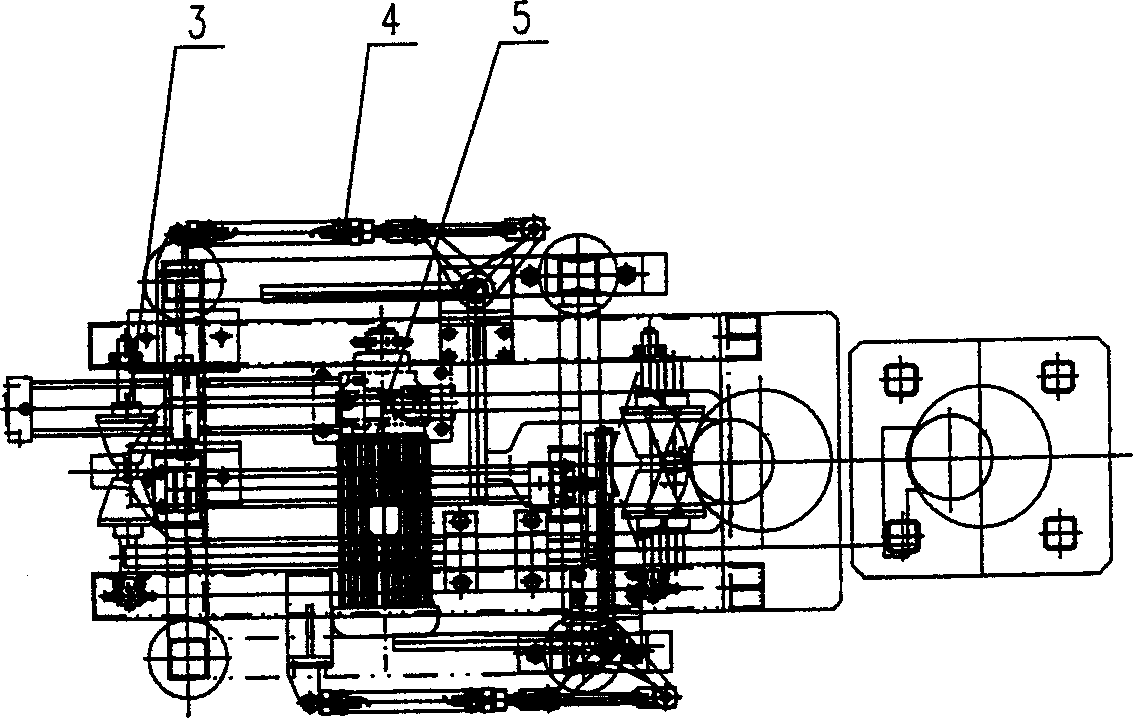

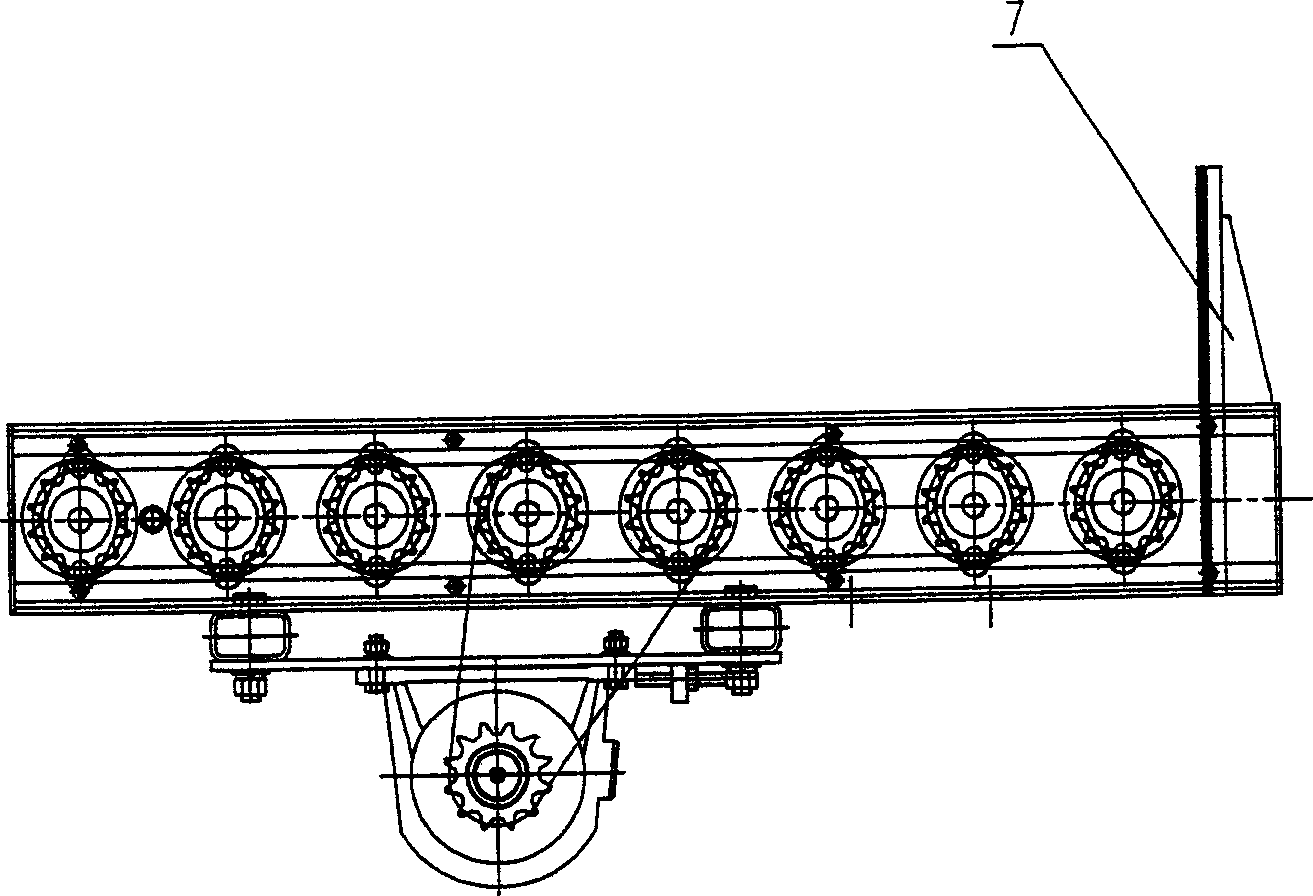

[0018] The present invention mainly consists of a turning power roller table 1, a storage table 2, a turning standing mechanism 3, a clamping mechanism 4, a propulsion mechanism 5, a sheet rack 6, an end baffle 7, a clamping cylinder 8, a cylinder connector 9, and a connecting rod. Assembly 10, fixed frame 11, cylinder tailstock 12, rotating rod assembly 13, fixed frame 14, overturning cylinder 15, cylinder fixed seat 16, cylinder connector 17, connecting rod assembly 18, hinged seat 19, cylinder fixed seat 20, Propel cylinder 21, cylinder fixed seat 22, cylinder fixed seat 23, steel cylinder push head 24, rotating shaft 25, bearing block 26 and other parts and form.

[0019] The present invention mainly uses the sheet frame 6 to be fixed to the ground through expansion bolts; the storage table 2 is fixed on the ground through expansion bolts; the turn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com