Microwave ceramic element detection clamp and device, and detection method thereof

A technology of components and test fixtures, applied in the direction of measuring devices, parts of electrical measuring instruments, instruments, etc., to achieve the effects of accurate data, good repeatability, and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

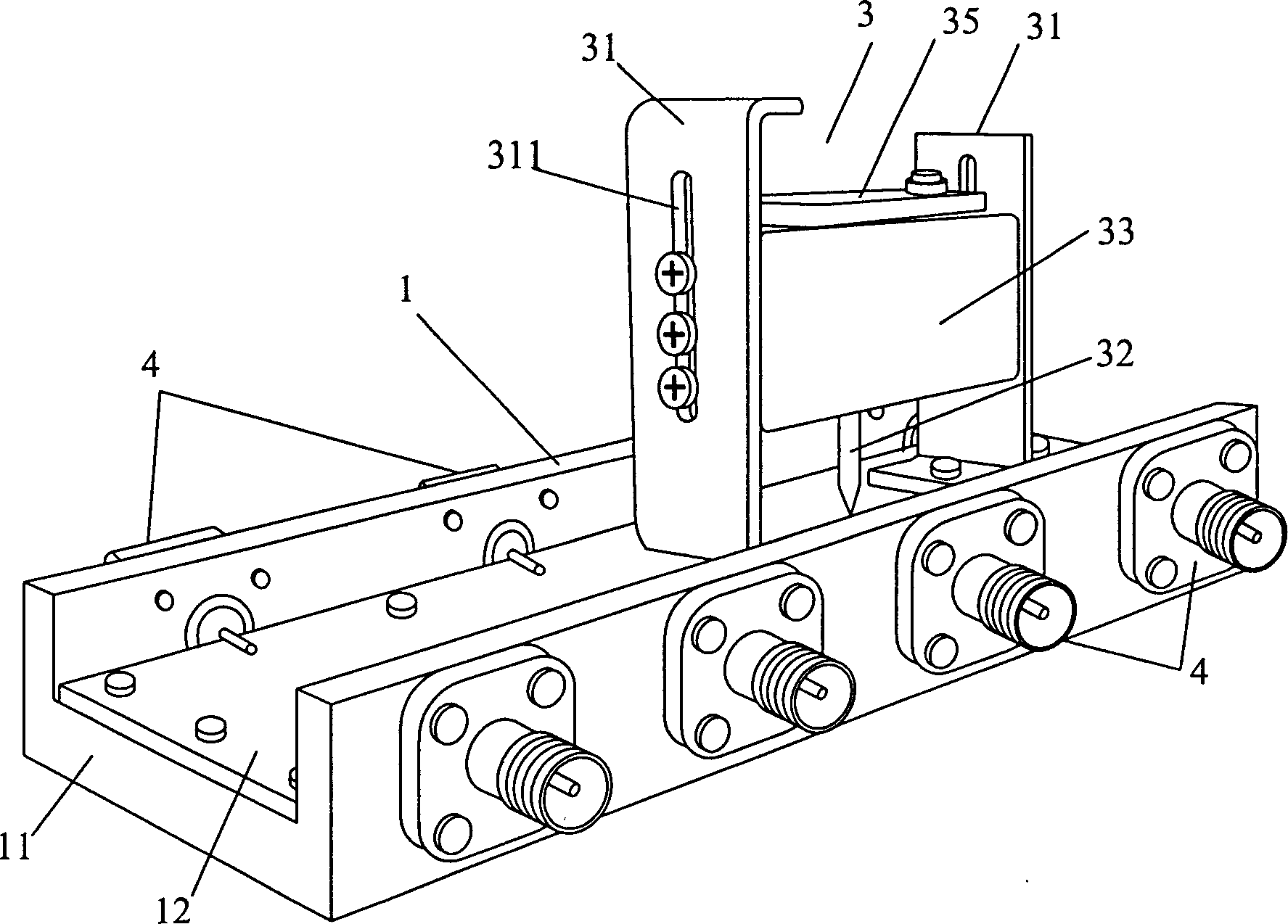

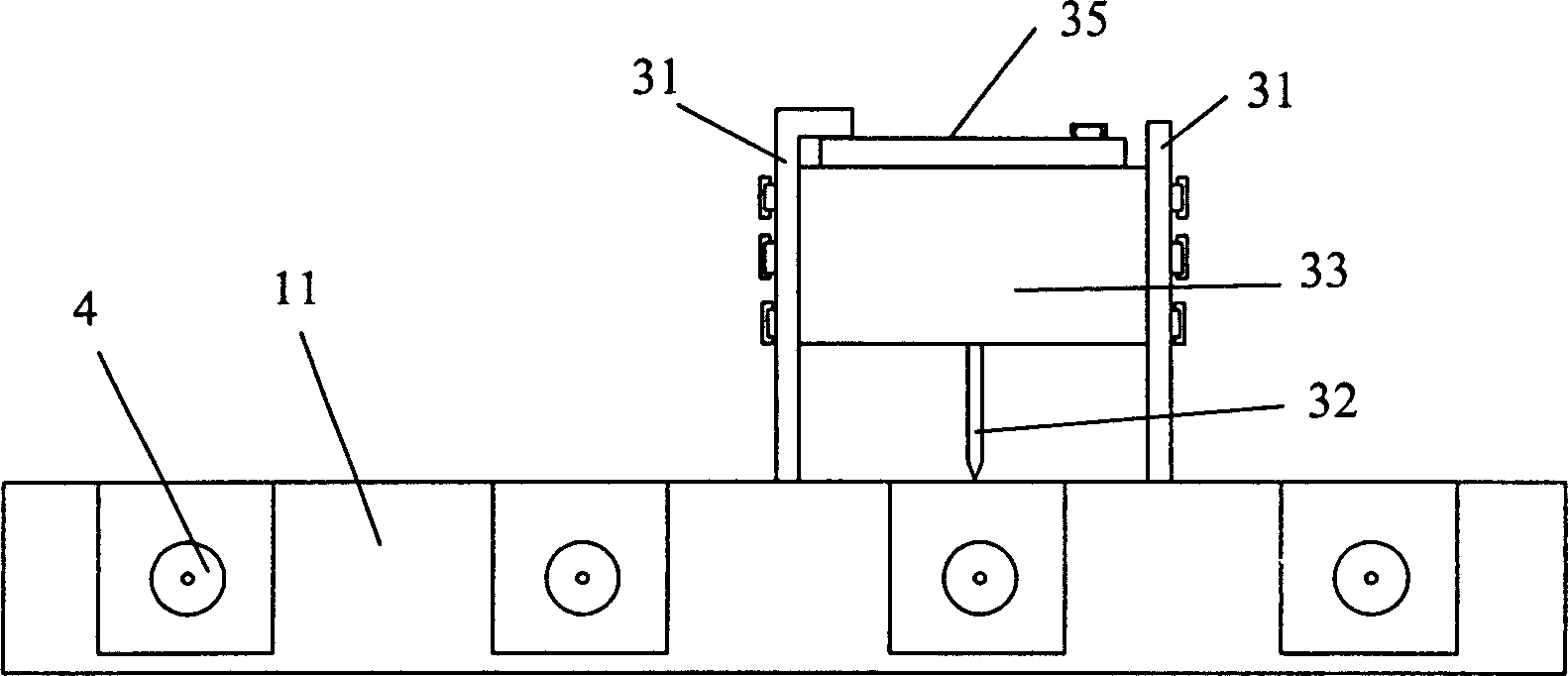

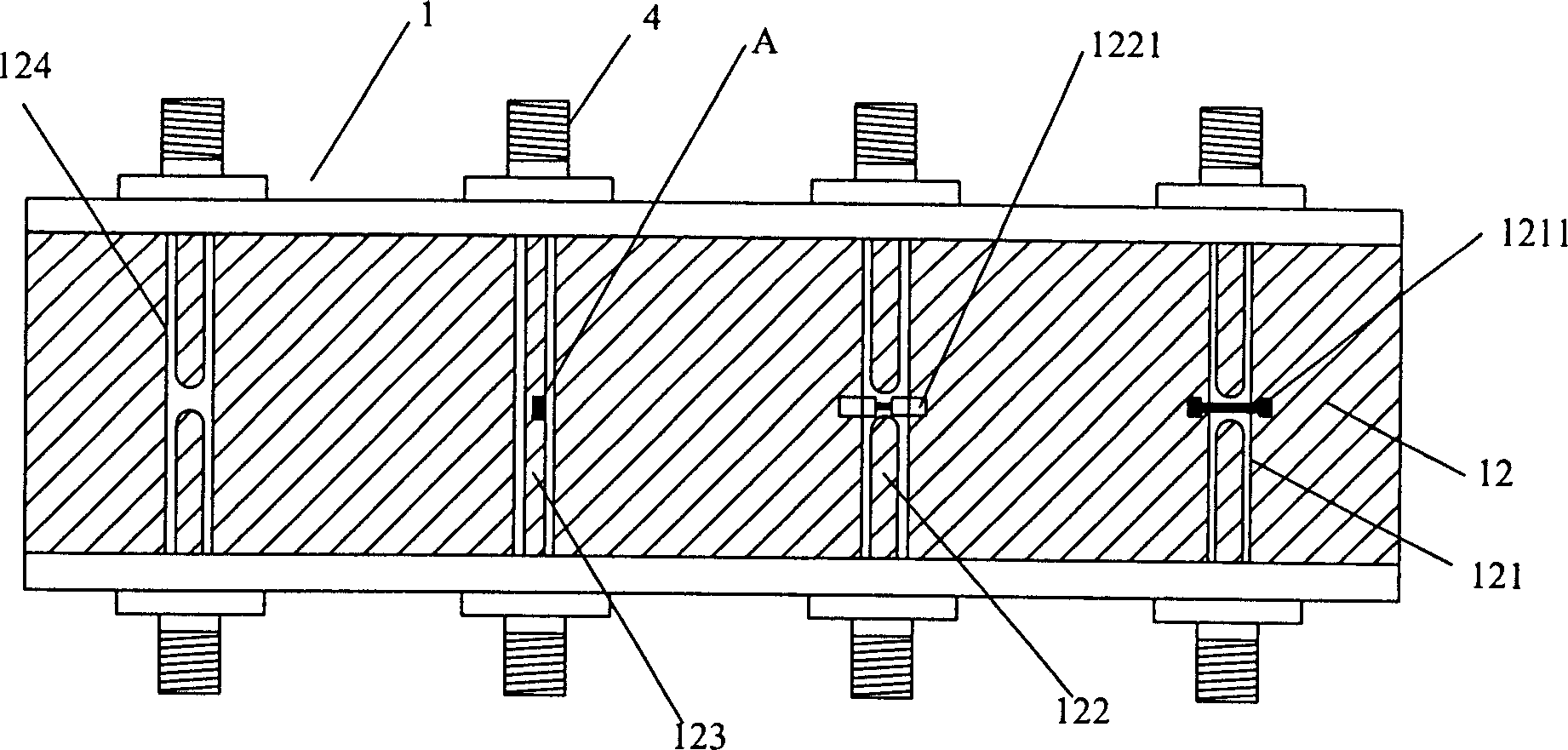

[0029] see Figure 1-5 , The microwave coplanar waveguide test fixture is provided with a microwave coplanar waveguide 1, a sample positioning piece 2, a detection probe holder 3 and an SMA connector 4. The microwave coplanar waveguide 1 is provided with a waveguide base 11, a high-frequency printed circuit board 12 and fasteners, the high-frequency printed circuit board 12 is fixed on the waveguide base 11 by the fasteners, and a short circuit Open calibration channel 121, matching calibration channel 122, parallel detection channel 123 and series detection channel 124, one end of the short-circuit open calibration channel 121 is a short-circuit calibration load, and the other end is an open-circuit calibration load, and a short-circuit line 1211 is provided on the short-circuit open calibration channel The matching calibration channel 122 is a matc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com