Heat radiating structure and temperature control method

A technology of heating wire and heating temperature, applied in the direction of electric heating device, heating element, heating element shape, etc., can solve problems such as increasing cost, increasing failure rate, and causing fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

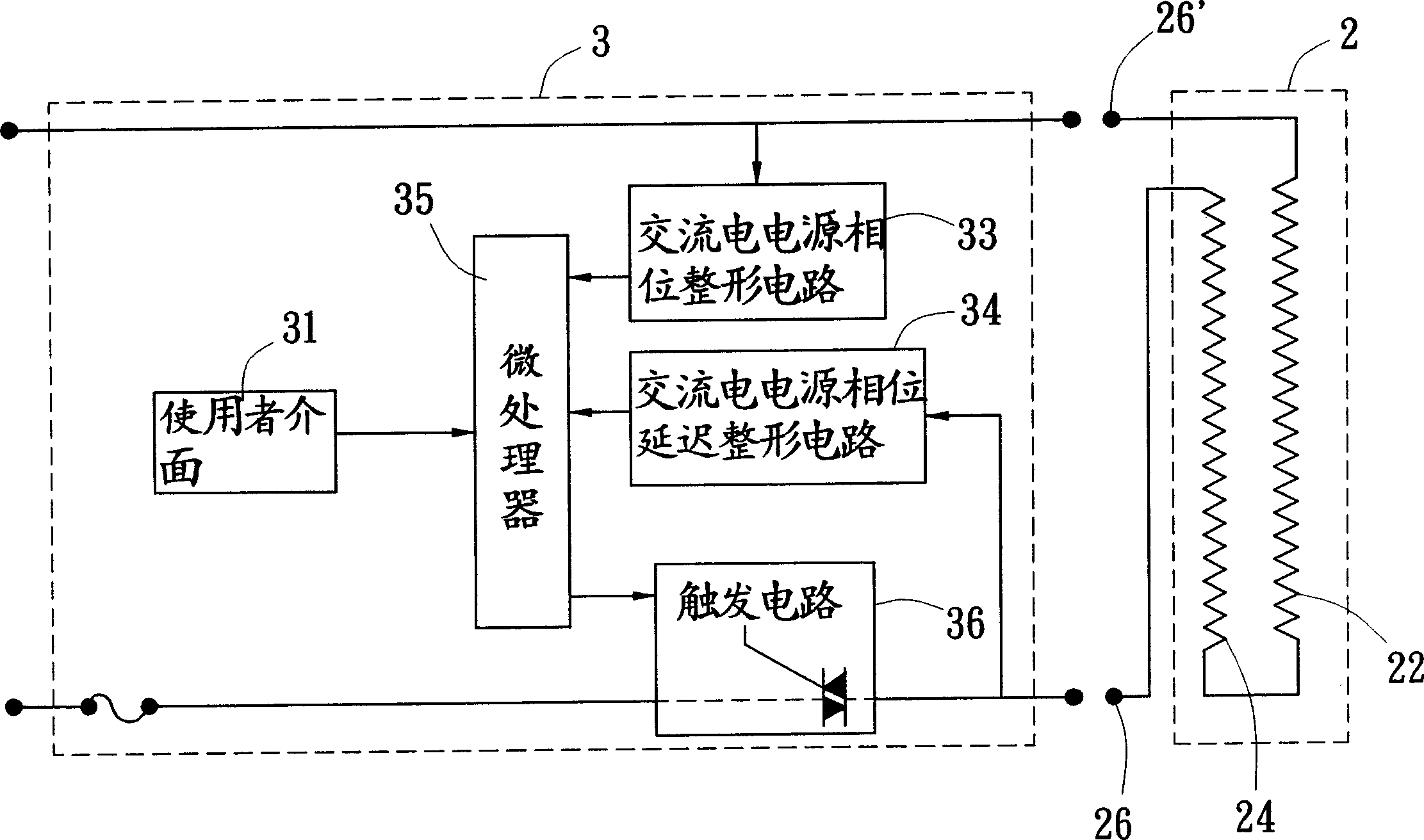

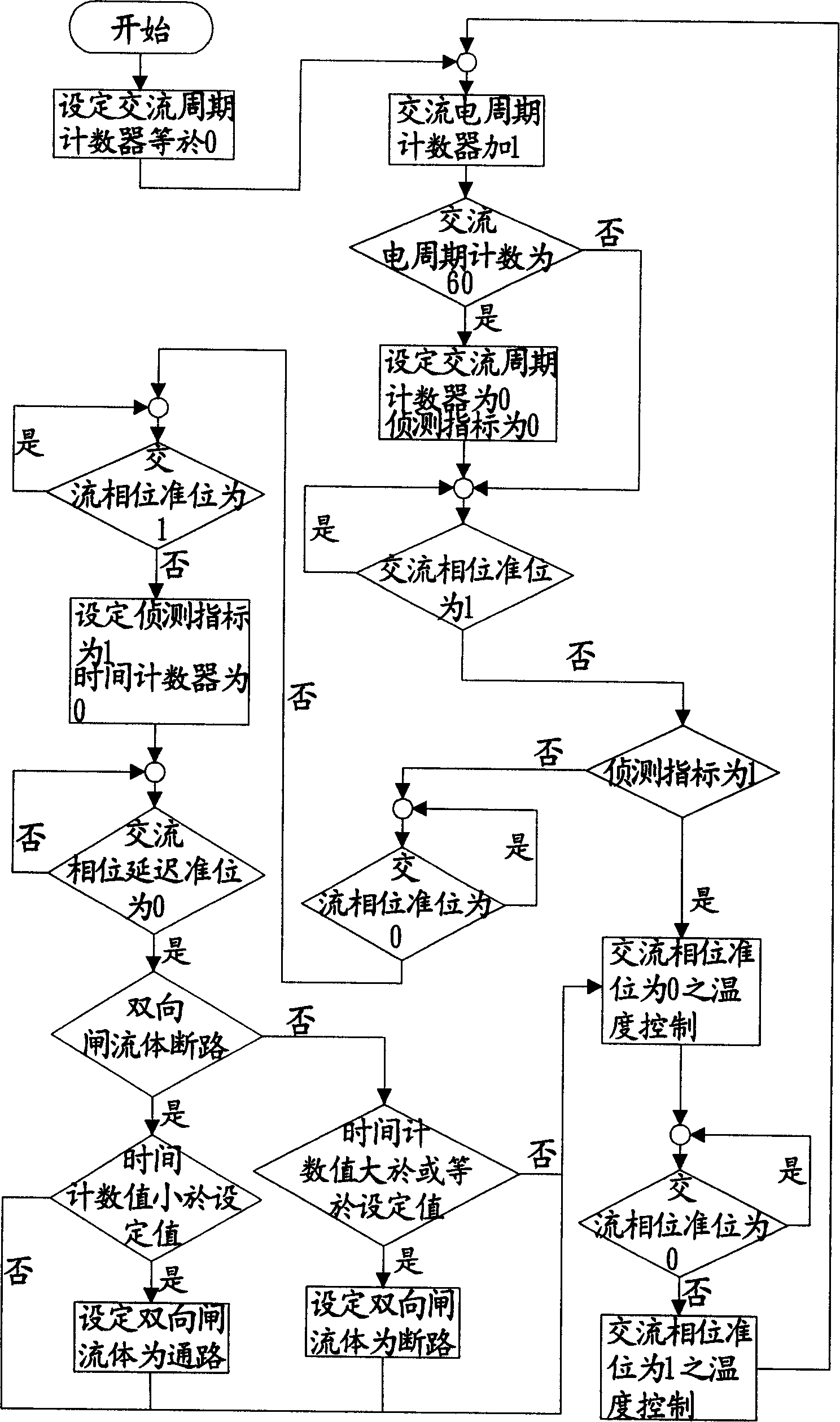

[0026] see figure 1 , the temperature control method of the heating structure of the present invention shown in Fig. 2, comprises the following steps:

[0027] a. The user sets the heating time and temperature through the user interface 31 and turns on the power.

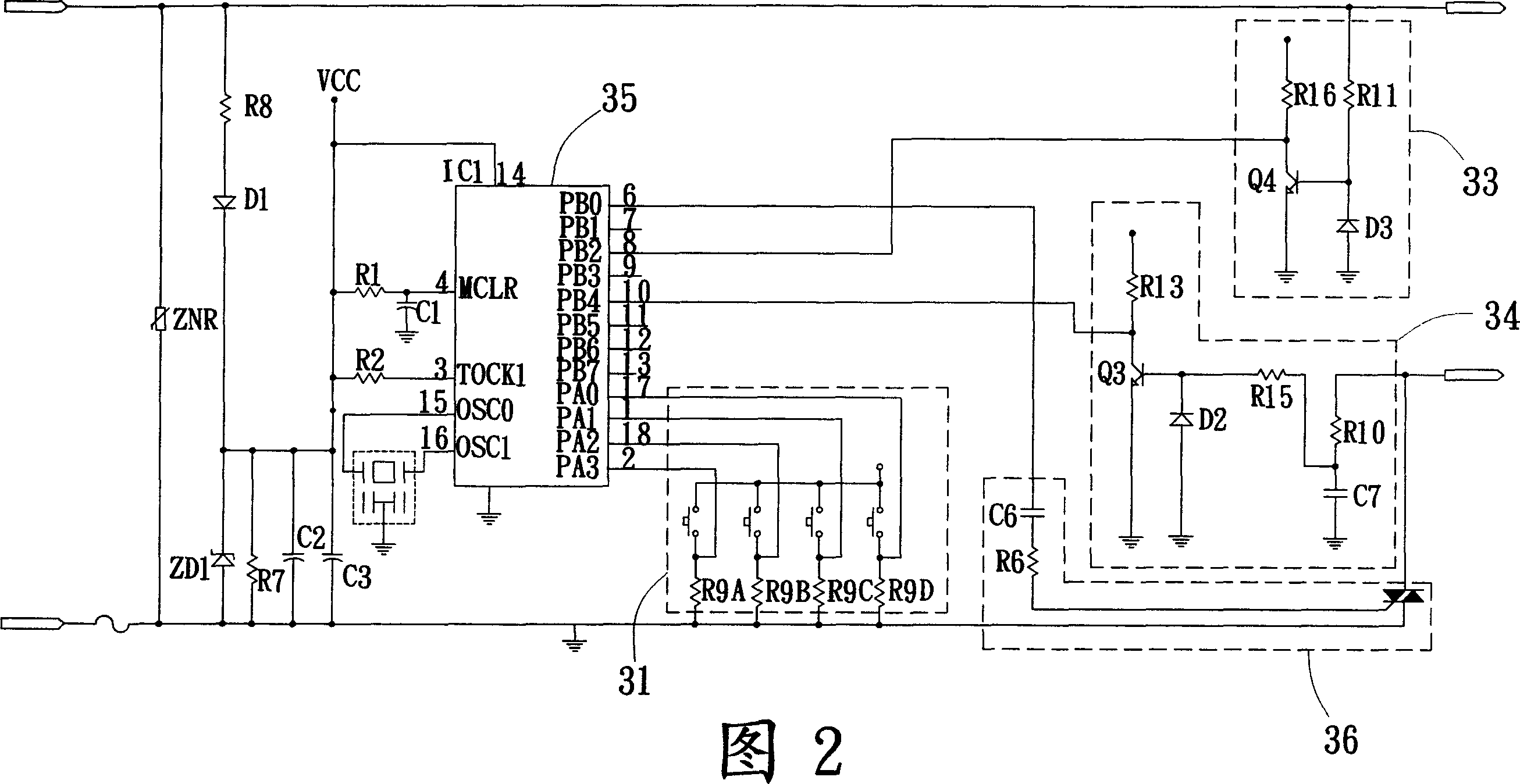

[0028] b. Heating the positive temperature coefficient component 22, and inputting part of the current into the AC power phase shaping circuit 33 to shape it into a DC square wave.

[0029] c. A part of the conduction current is shunted into the phase delay shaping circuit 34 of the AC power supply, so that the sine wave signal is delayed, and then converted into a DC square wave signal.

[0030] d. During the heating process of the PTC component 22, the microprocessor 35 performs timing detection and compares the phase shift between the DC square wave signals converted by the AC power phase shaping circuit 33 and the AC power phase delay shaping circuit 34 respectively.

[0031] e. Control the switch (TRIAC) of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com