Electric toothbrush

An electric toothbrush, vibration frequency technology, applied in brushes, dentistry, brush bodies, etc., can solve the problems of increased manufacturing cost, deterioration, and reduced plaque removal performance, and achieve the effect of reducing manufacturing cost and improving performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

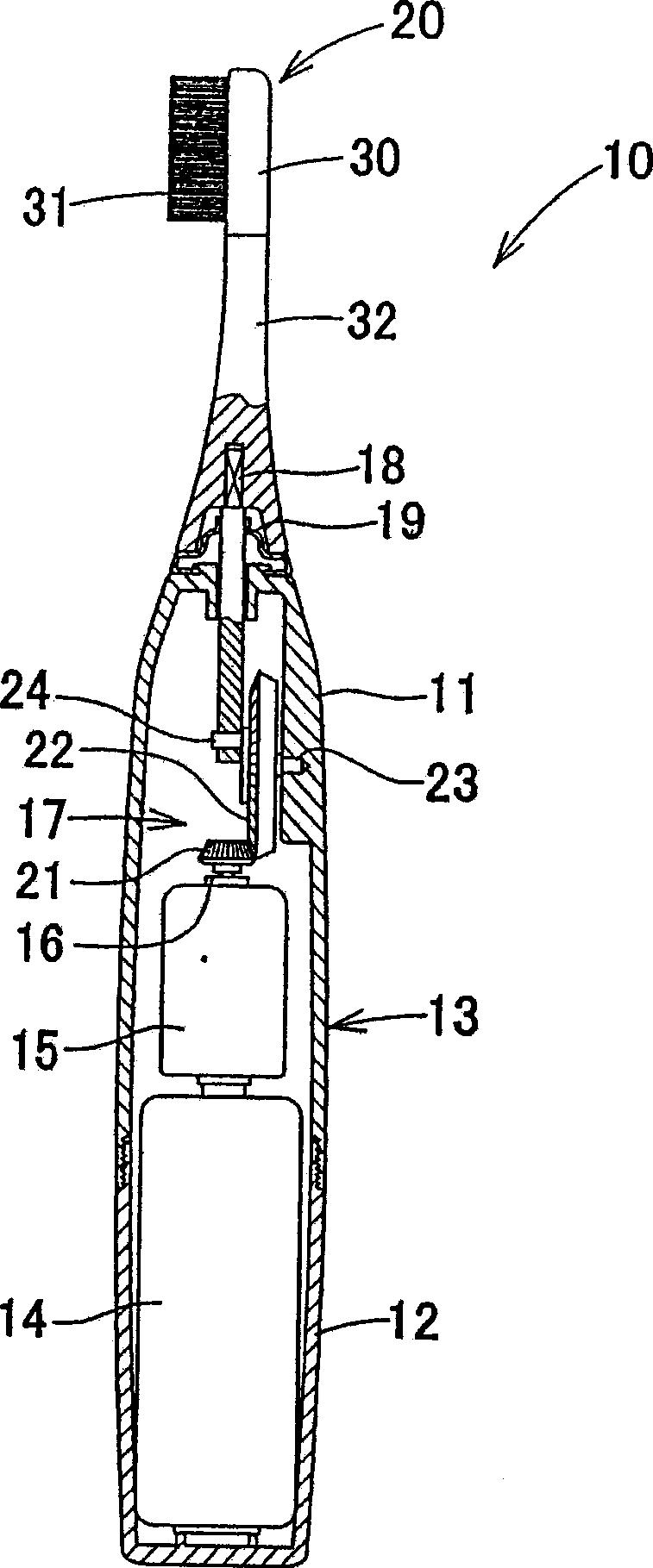

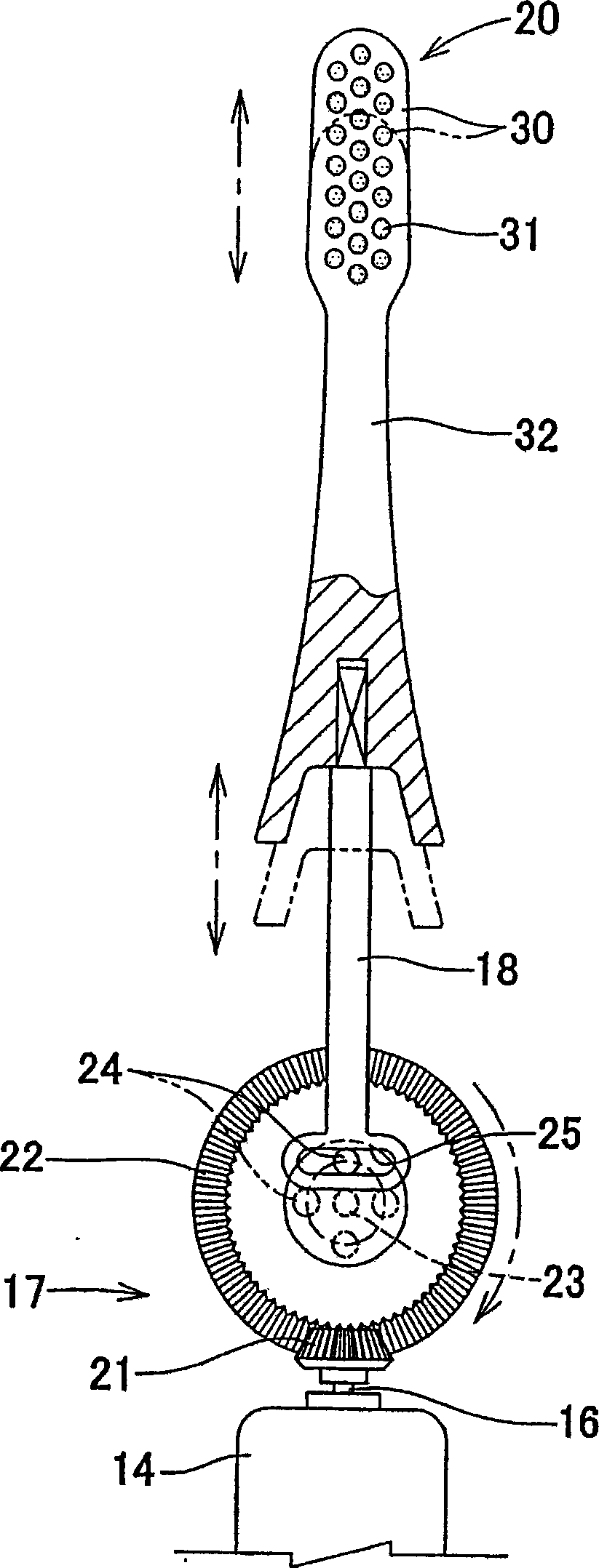

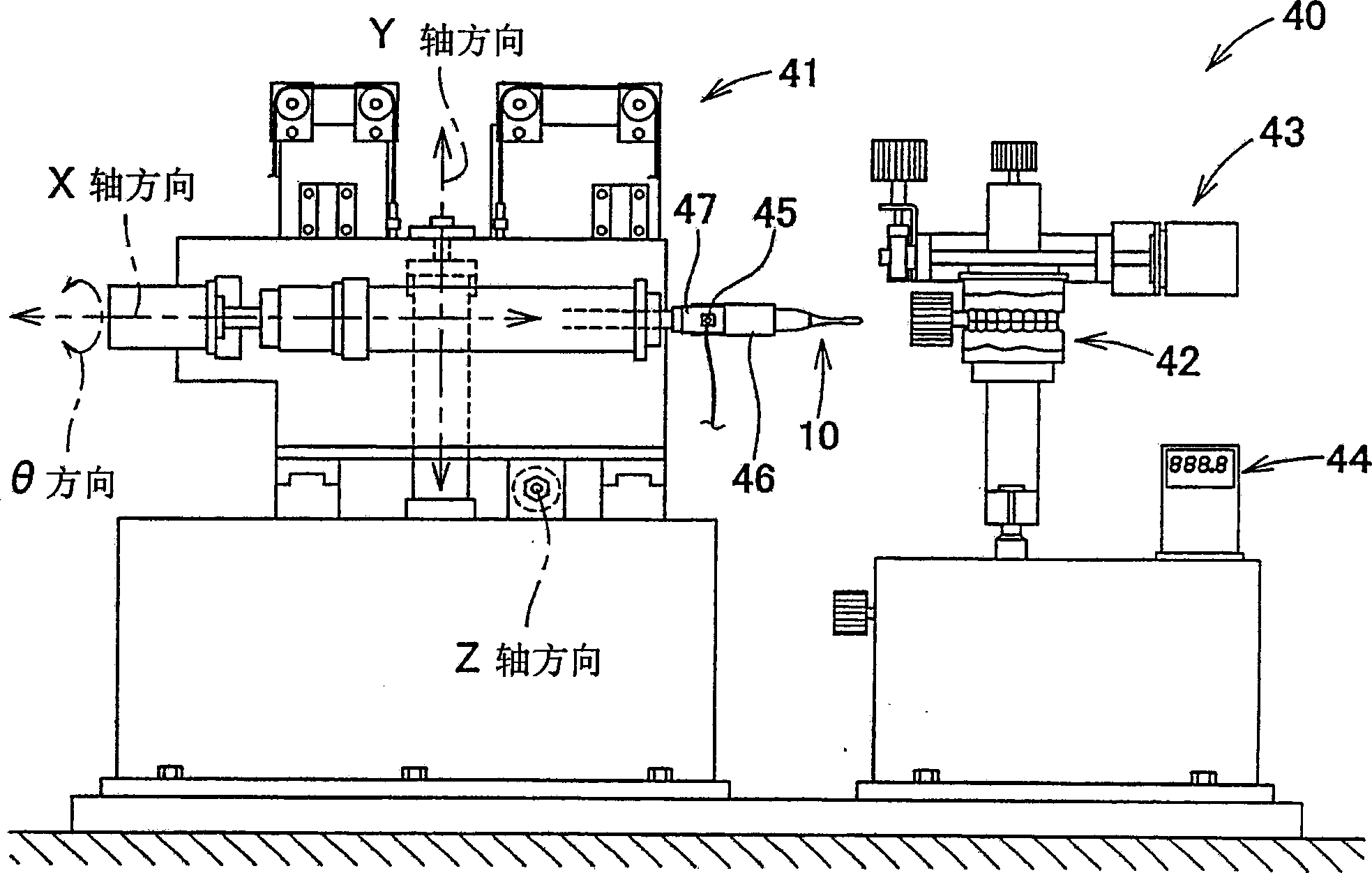

[0037] Hereinafter, embodiments of the present invention will be described with reference to the accompanying drawings.

[0038] In the present invention, in the electric toothbrush for brushing by the reciprocating linear motion of the hair-implantation part, the product of the moving distance (mm) of the bristles of the hair-implantation part and the number of reciprocating vibrations (times) in 1 minute is set at 3000-9000 Within the range of , preferably set within the range of 4500 to 7500, it can be applied to electric toothbrushes of any structure. In addition, in the electric toothbrush that is brushed by the reciprocating linear motion of the hair-implanting part, the moving distance x (mm) of the bristles of the hair-implanting part and the number of reciprocating vibrations y (times) of the hair-implanting part in 1 minute are set to satisfy Within the range of the following formula, it can be applied to electric toothbrushes of any structure:

[0039] y=ax+b

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com