Four-cycle engine

A four-stroke engine, engine technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve problems such as cost increase, and achieve the effects of suppressing deviation, promoting activation, and improving exhaust gas purification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be described below in conjunction with the drawings.

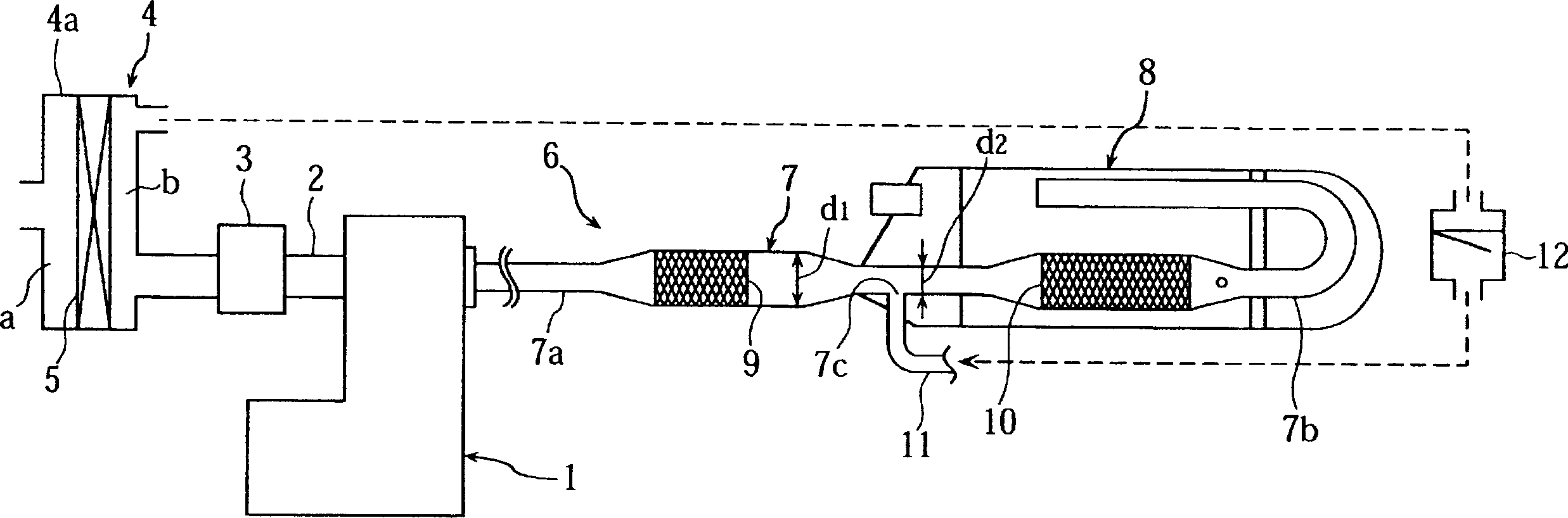

[0025] figure 1 It is a schematic diagram for explaining a four-stroke engine according to an embodiment of the present invention according to claims 1, 3, and 4.

[0026] In the figure, reference numeral 1 denotes a four-stroke engine used in a motorcycle such as a motorcycle or a scooter. The intake passage 2 is connected to an intake port (not shown) of the engine 1, a carburetor used as a fuel supply system is provided in the middle of the intake passage 2, and an air cleaner 4 is connected to the upstream end of the intake passage 2 . The structure of the air cleaner 4 is such that the inside of the filter case 4a is partitioned into the air suction side "a" and the discharge side "b" by the member 5.

[0027] The carburetor 3 includes an idling system working in the idle and low-speed driving zones and a main system working in the medium-speed and high-speed driving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com