Method and plant for the treatment of materials, in particular waste materials and refuse

A technology of equipment and reactors, applied in the field of waste and garbage, can solve the problems of not eliminating the cold zone and inclusions at the supply end of the reactor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

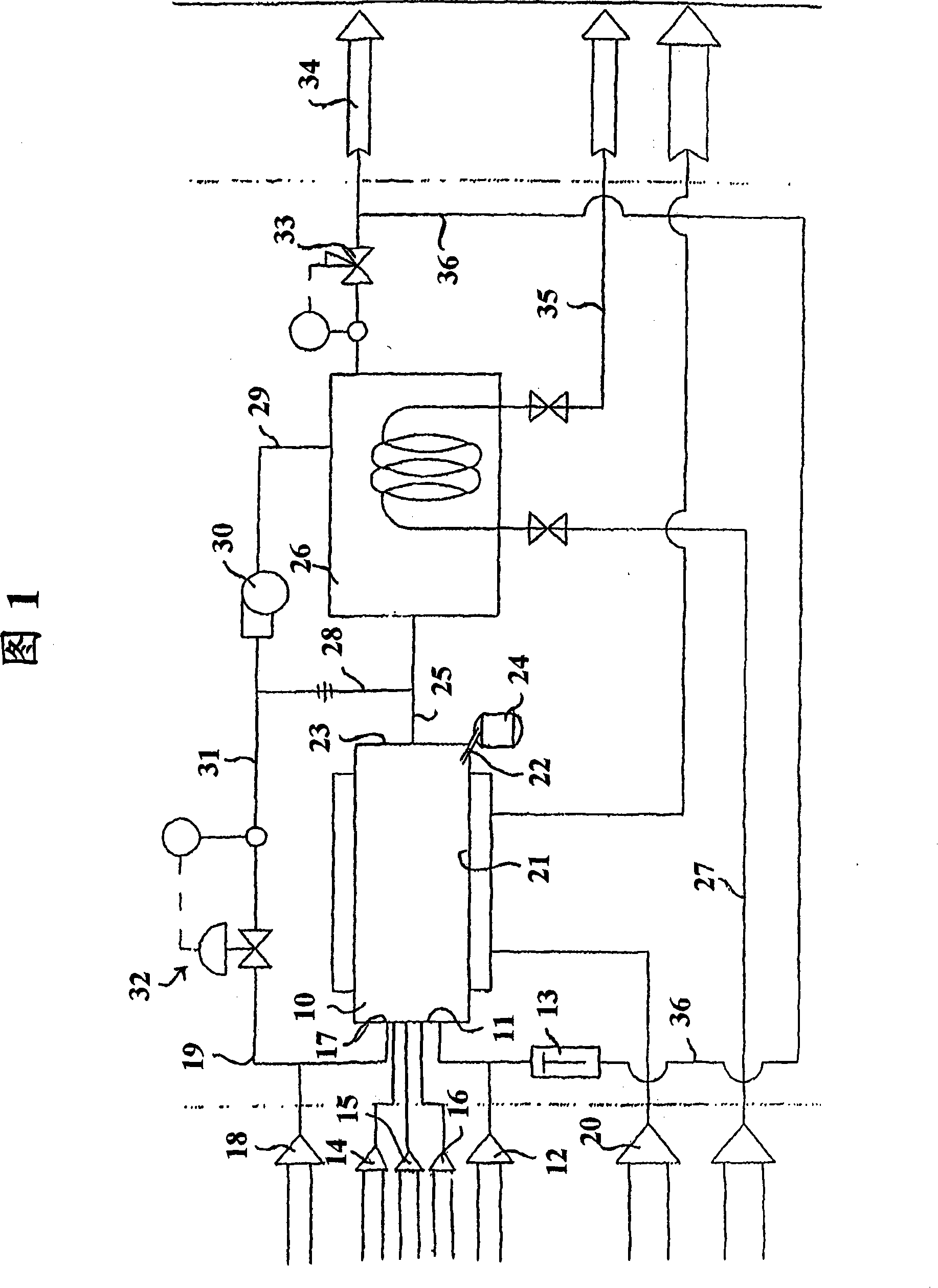

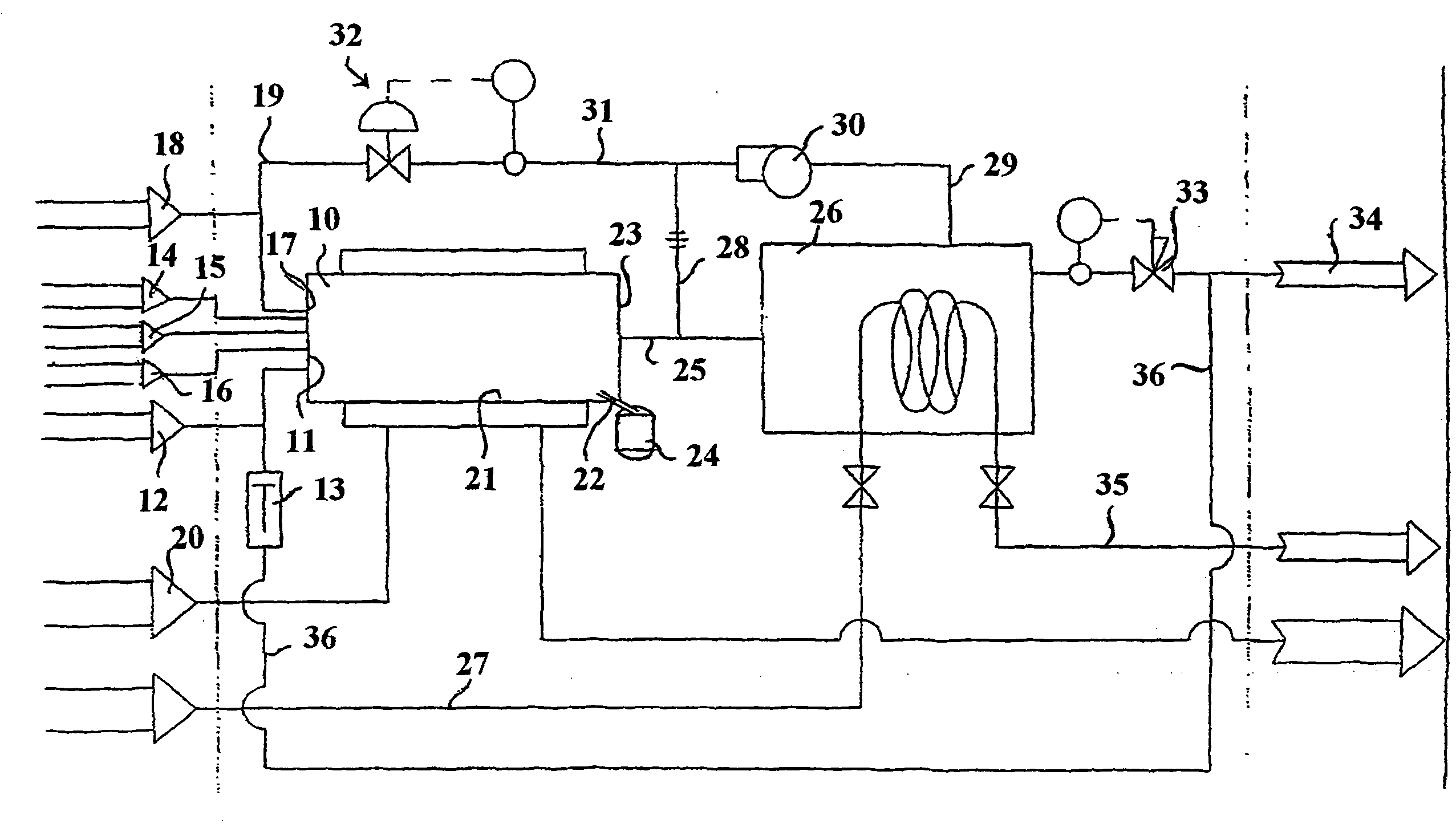

[0030] look now figure 1 , the material treatment plant comprises an oxidation reactor or oxidation chamber 10 having at least one input port 11 through which material to be treated is supplied. In particular, the apparatus of the present invention can handle coarse-grained sheet-like solid material fed through feeder 12 and push chamber 13, granular material fed through feeder 14, and supplied to the reactor via feeder 15. A liquid in a liquid consisting roughly of a mixture of water with suspended and settled solids, viscous bitumen, or slurries of various densities and compositions. Gaseous material can likewise be conveyed into the reactor via feeder 16 .

[0031] Reactor 10 also comprises an inlet 17 to which oxygen is supplied from line 18 mixed in a certain proportion with recirculated fumes from line 19 according to a program which will become clear from later in this description. Depending on the material being processed, a predetermined flow of steam may be introdu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com