Control method for measuring colour difference

A control method and color measurement technology, applied in the direction of color measurement using electric radiation detectors, color measurement devices, etc., can solve the problems of large errors, the inability to quantitatively determine the specific number of color differences, and the inability to judge test products, etc., to achieve The effect of small error, easy operation and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

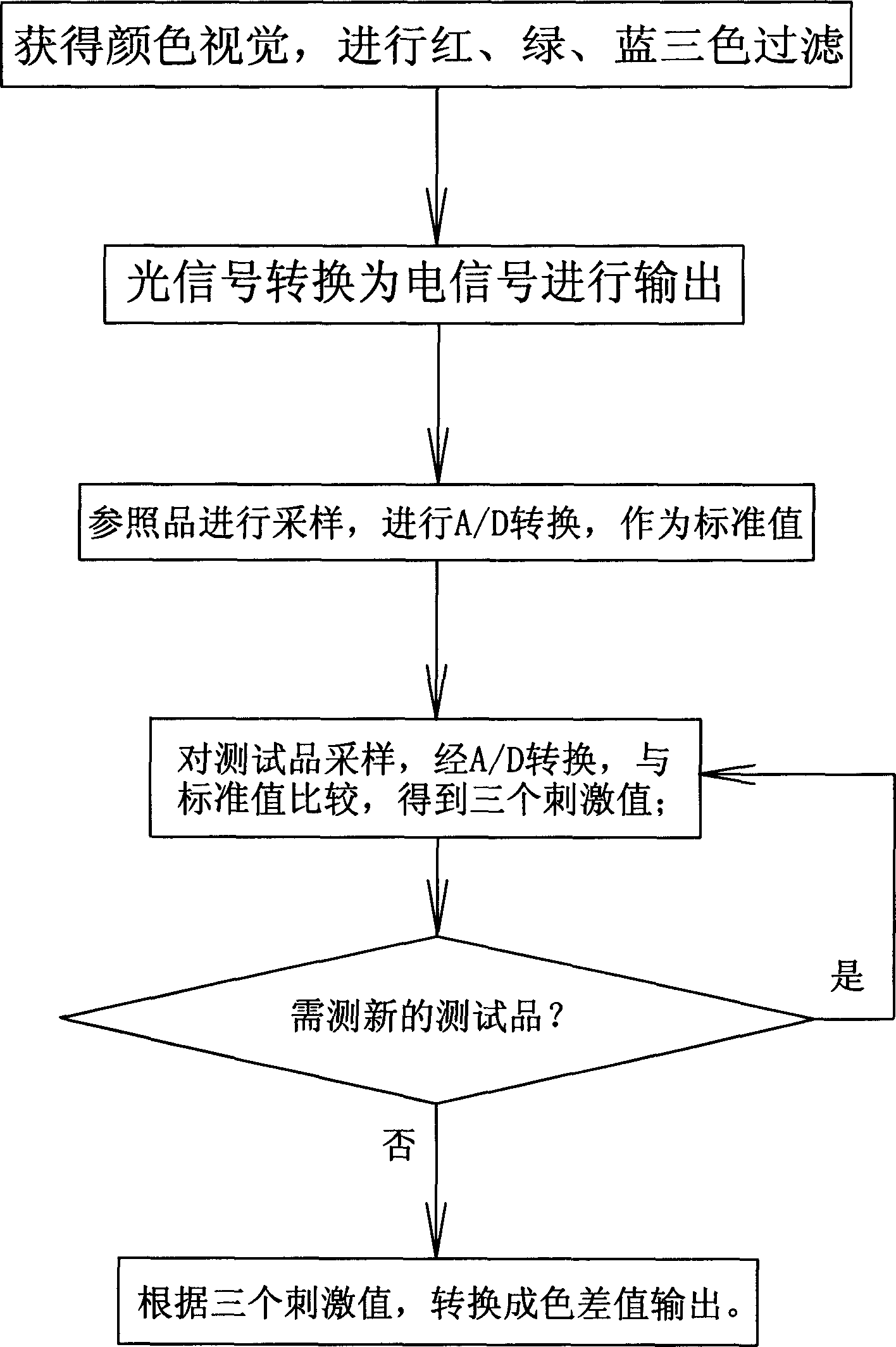

Method used

Image

Examples

Embodiment 1

[0024] Embodiment one: measure the chromatic aberration of dilute red ink

[0025] Add two drops of red ink in the water, and under the background of the standard lighting body D65, first test the color vision of the water with the sampling sensor (probe), pass the red, green and blue filters for the color vision, and then put the The optical signal obtained by filtering is converted into an electrical signal by a photodetector, and then the electrical signal is converted by A / D, and the value is set to zero; then the probe is used to test the thin red ink, and the color vision is filtered by three colors The optical signal obtained after the film is converted into an electrical signal by a photodetector, and then the value obtained by A / D conversion is the tristimulus value (X, Y, Z) of the dilute red ink.

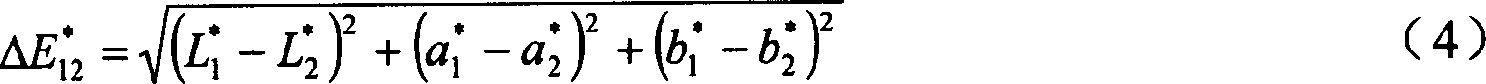

[0026] Convert tristimulus values (X, Y, Z) into lightness (L * ) and chroma (a * , b * ), calculated by the following formula:

[0027] L * =116(Y / Y n ) 1 / 3 -16...

Embodiment 2

[0033] Example 2: Two different patterns on the same white paper

[0034] Under the background of the standard illuminant D65, first test the color vision of the white paper with the sampling sensor (probe), pass the red, green and blue color filters for the color vision, and then pass the light signal obtained by the filter through the photoelectric The detector is converted into an electrical signal, and then the electrical signal is converted through A / D, and the value is set to zero; then the probe is used to test one of the patterns, and the optical signal obtained by the color vision through the three-color filter, It is converted into an electrical signal by a photodetector, and then the value obtained through A / D conversion is the tristimulus value (X 1 , Y 1 ,Z 1 ); and then test another pattern with the probe, the optical signal obtained by the color vision through the three-color filter, and then converted into an electrical signal by the photodetector, and then t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com