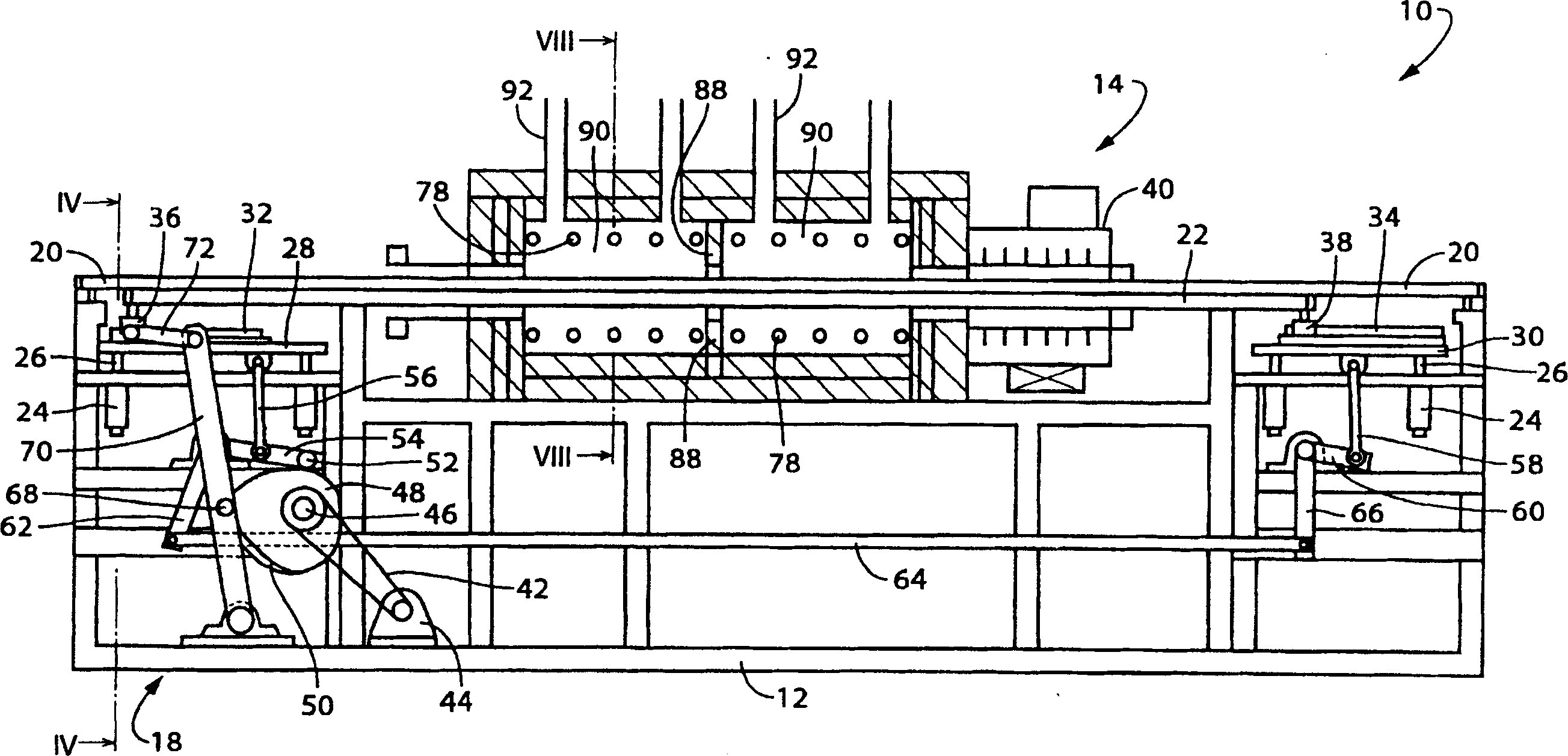

Step forward heat treatment device

A heat treatment device, step-by-step technology, used in lighting and heating equipment, furnace types, furnaces, etc., can solve the problems of solar cell characteristics changes, uneven characteristics, substrate changes, etc., to shorten the rise time or heat treatment time. , The beam drive mechanism is simple, lightweight and rigid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

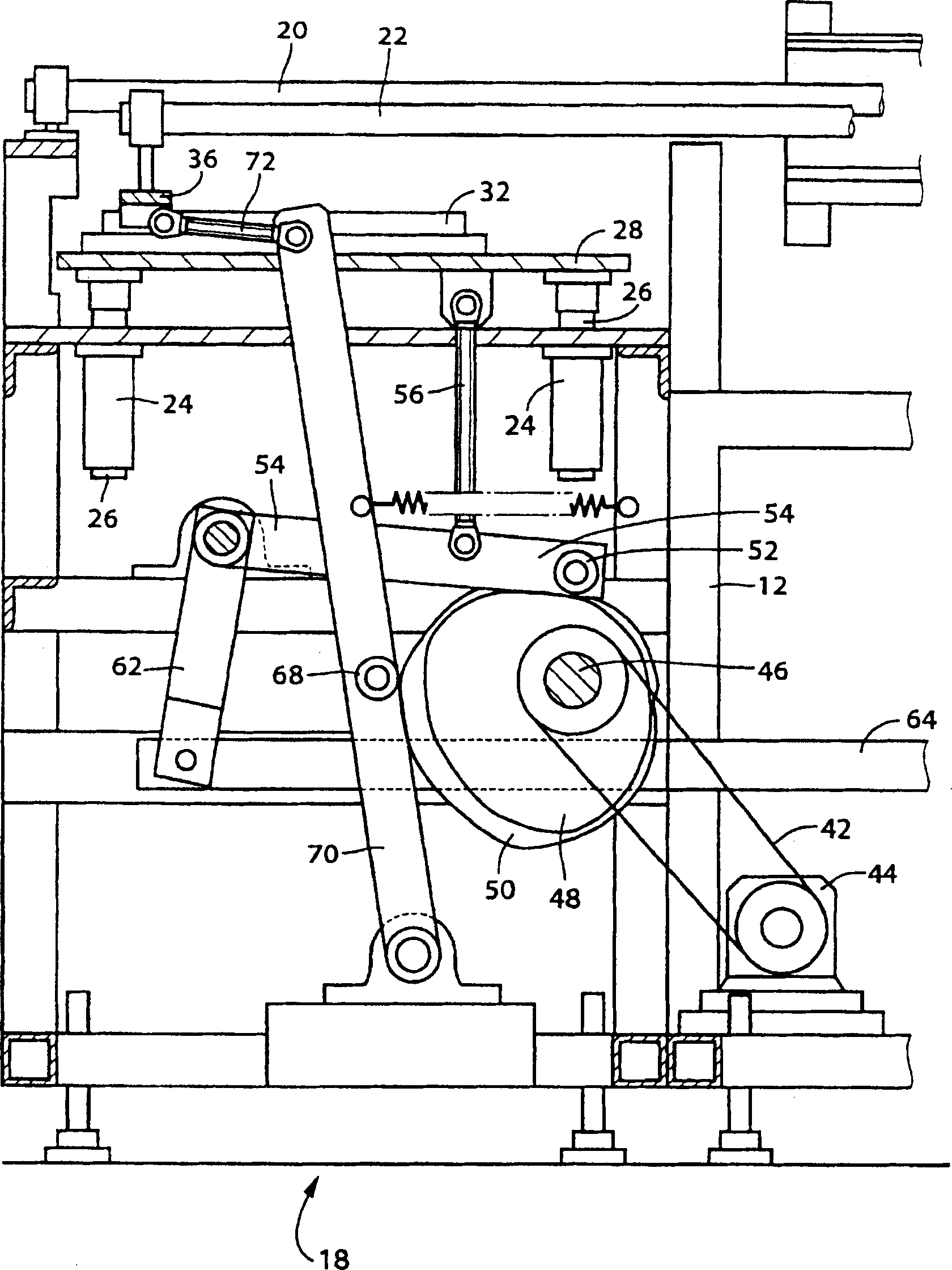

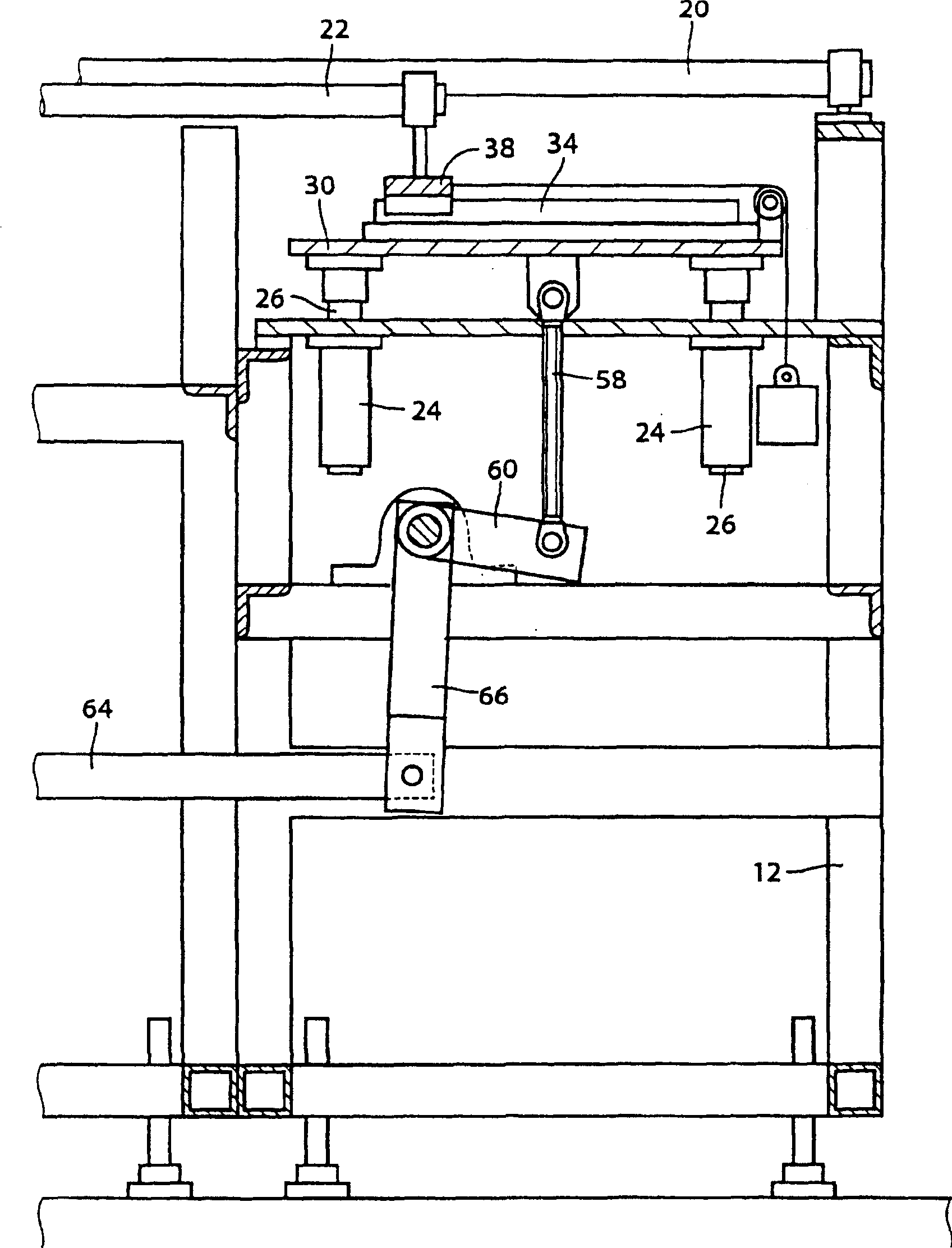

Method used

Image

Examples

Embodiment Construction

[0055] Here, preferably, among the transparent ceramics constituting at least a part of the first beam and / or the second beam, the term "transparent" means that it can help the radiant energy from the heating body to pass through the transparent ceramics. Reaching the lower surface of the substrate, the transmittance of the degree of uniform heating and rapid heating of the substrate is realized. For example, when using a heater that emits near-infrared rays, it means transparency that can be transmitted to the extent that the near-infrared rays can help the near-infrared rays reach the bottom of the substrate to achieve uniform heating or rapid heating of the substrate. In visible light of other wavelengths heated, there is no problem even if it becomes cloudy (opaque). Determined based on the wavelength of radiation from a heating body for radiative heating of the substrate.

[0056] In addition, it is preferable that the heater used for radiatively heating the substrate is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com