Sticking-element section sample, its making method and viewing method

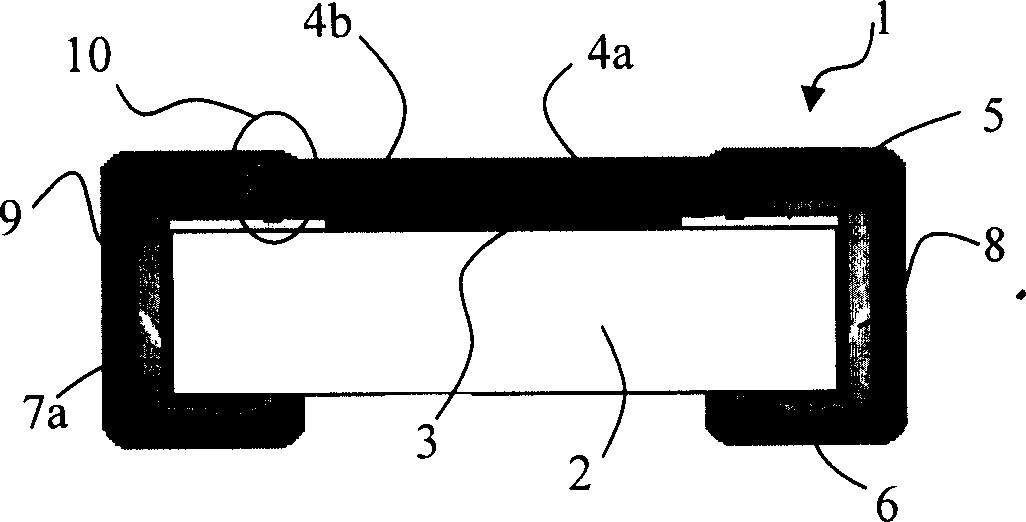

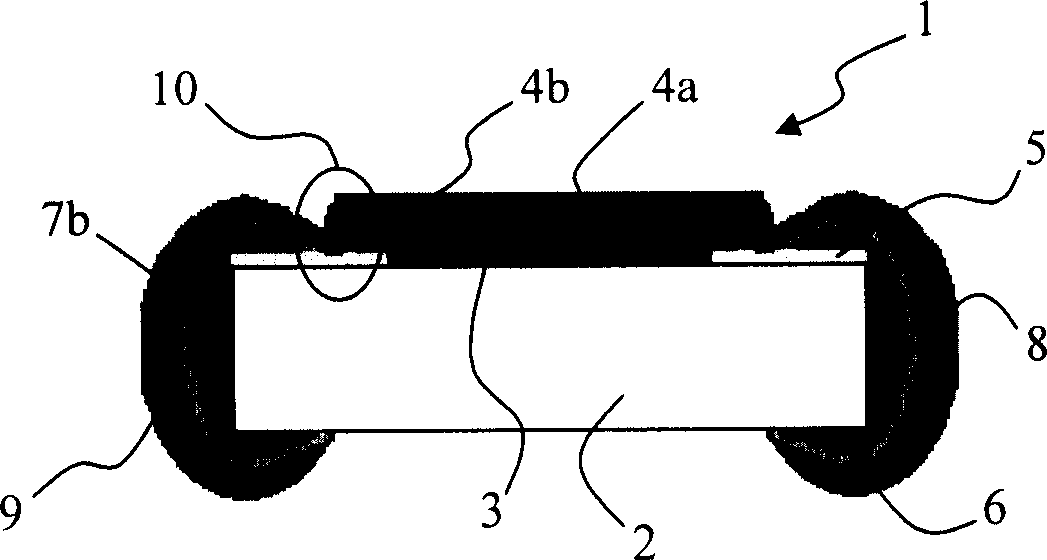

A manufacturing method and surface-mounting technology, which are applied in surface-mounting component section preparation, surface-mounting component section-section sampling preparation method and observation field. The electrode morphology is clear and beautiful, and the clarity is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Referring to FIG. 5 , the cross-sectional sample preparation A of surface-mount resistors according to the prior art includes a colorless and transparent epoxy resin matrix 20 and surface-mount resistors 1 embedded in the matrix 20. flush. Surface mount resistor cross-section samples B, C and D according to the present invention include colored and transparent epoxy resin substrates 21 , 22 and 23 and surface mount resistors 1 embedded in the substrates 21 , 22 and 23 .

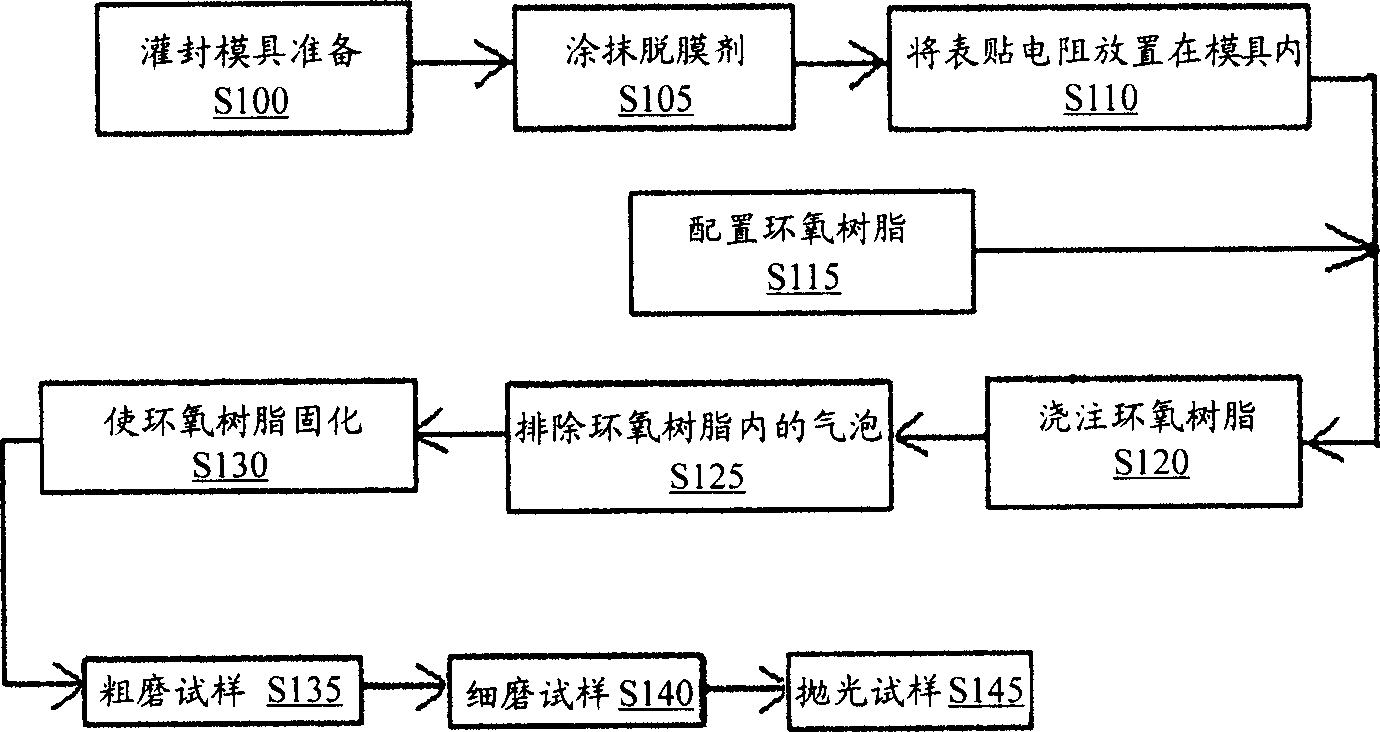

[0048] see Figure 6 , taking surface mount resistor section sample preparation as an example, describe the preparation method of surface mount component section sample preparation according to the present invention. The method comprises the steps of:

[0049] Step S200, providing a mold for potting;

[0050] Step S205, apply a release agent in the inner cavity of the mold, so that the sample preparation can be released from the mold in the subsequent procedure;

[0051] Step S210, placing the surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com