Method for detecting moisture regain of novel textile fabric

A technology for textile materials and moisture regain, which is applied in the direction of analysis and sampling devices using nuclear magnetic resonance, which can solve the problems of test interruption, scorching, improper heating, etc., to improve measurement accuracy, reduce production costs, and consume less samples. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

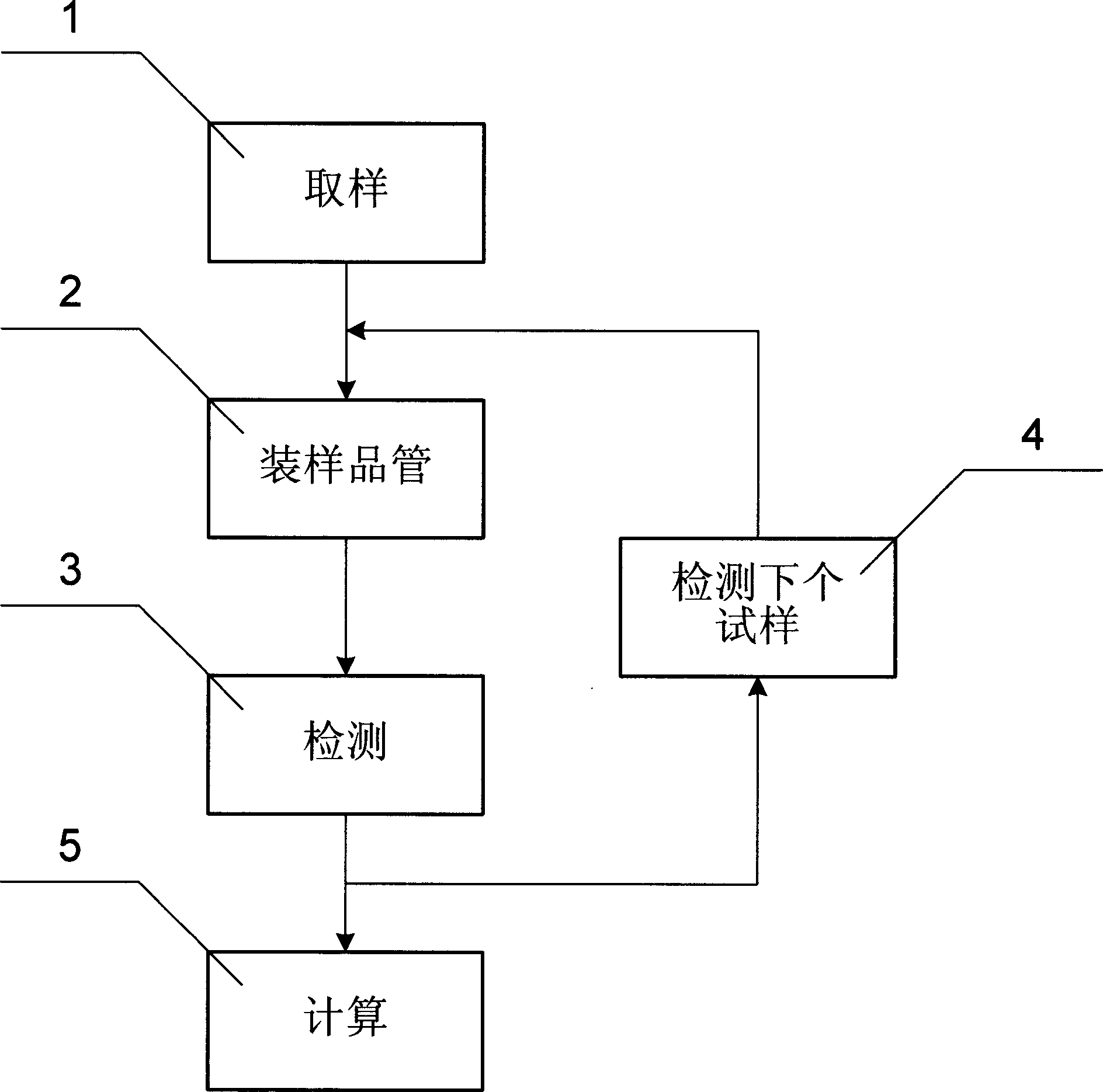

[0017] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0018] see figure 1 , Sampling 1: According to the test requirements of nuclear magnetic resonance technology, sample the textile materials that need to be tested in each process. If necessary, use a high-precision electronic balance to weigh the weight of each sample to be tested, the number of samples to be tested and the sampling method Determined according to the requirements of statistics. Loading sample tube 2: place the tested sample in the sample tube; the diameter of the sample tube for placing the tested sample is 5-40 mm, so that the tested samples of various textile materials can be placed in the sample tube. Detection 3: Measure the area of the absorption peak corresponding to the transverse relaxation time T2 of the free water in the tested sample by using a nuclear magnetic resonance spectrometer, and calculate the weight of the free wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com