Non-fermented broth freezed dough and production thereof

A technology for frozen dough and a production method, which is applied in the field of food processing, can solve the problems of difficulty in realization, large differences in product quality, and complicated processing of Miaofu, and achieves moderate taste, improves the effects of preventing constipation and preventing cardiovascular diseases.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

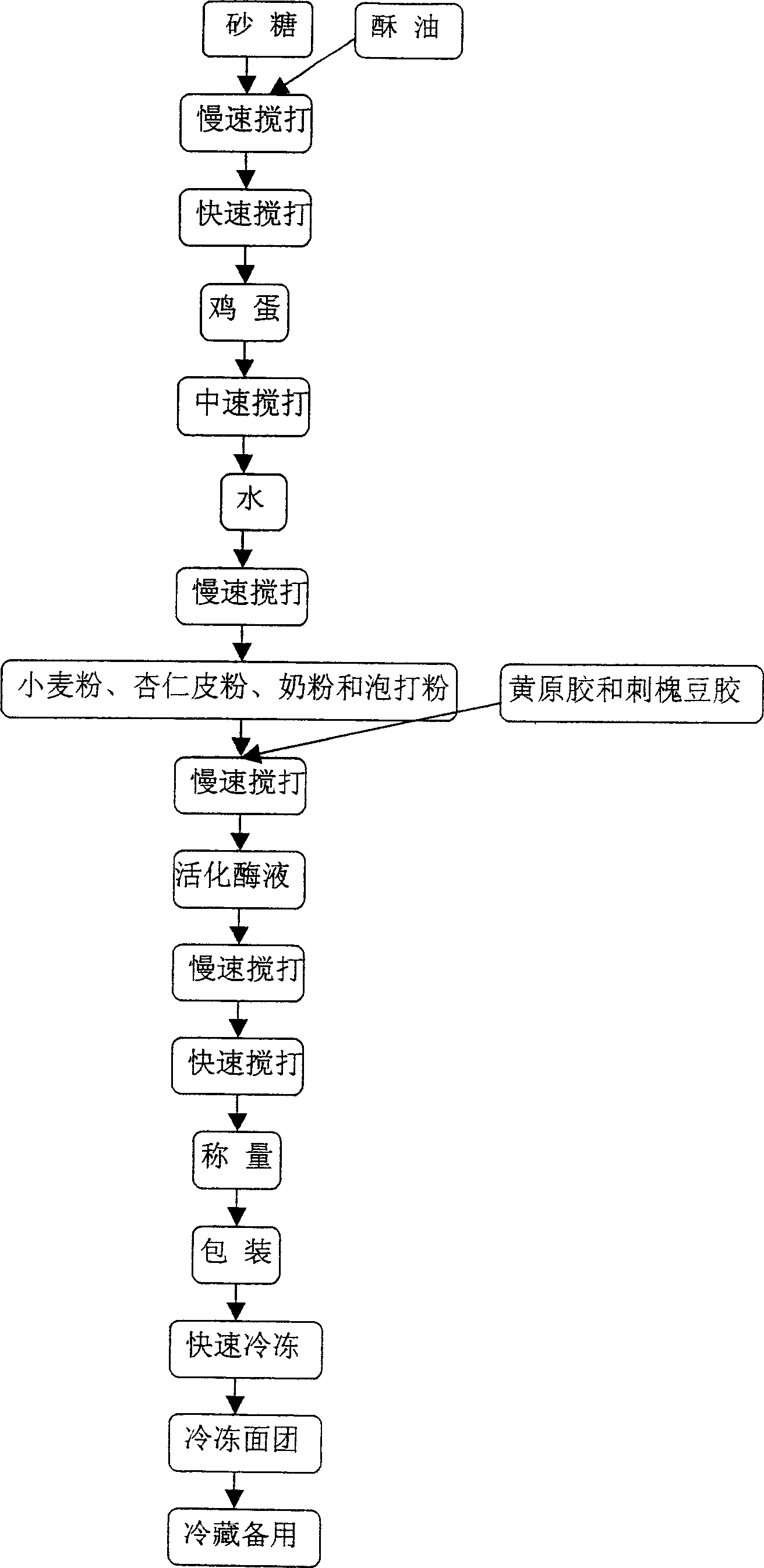

Image

Examples

Embodiment 1

[0019] In the embodiment of the present invention, wheat flour: 29% by weight, almond skin powder: 3% by weight, granulated sugar: 15% by weight, ghee: 19% by weight, baking powder: 1% by weight, eggs: 20% by weight, Salt: 0.13% by weight, milk powder: 3% by weight, water: 9.8075% by weight, xanthan gum: 0.029% by weight, locust bean gum: 0.030% by weight, β-glucanase: 0.002% by weight , Pentosanase: 0.0015% by weight.

[0020] First, dissolve β-glucanase and pentosanase in an appropriate amount of water to prepare an enzyme solution respectively, the solution concentration is: 3% by weight, and place it in a 28°C constant temperature incubator for activation; put the ghee and granulated sugar into the stirring solution first Whip in the cylinder at a slow speed (level 1) for 1 to 2 minutes, and then change to a fast whipping (level 3) after stirring well, and after sending (that is, the material in the cylinder changes from yellow to white, it takes about 15 minutes) Add egg...

Embodiment 2

[0022] In the embodiment of the present invention, 5% by weight of wheat flour, 27% by weight of almond skin powder, 17% by weight of granulated sugar, 18% by weight of ghee, 1% by weight of baking powder, 19% by weight of eggs, and 10% by weight of salt, : 0.13% by weight, milk powder: 3% by weight, water: 9.8065% by weight, xanthan gum: 0.029% by weight, locust bean gum: 0.030% by weight, β-glucanase: 0.003% by weight, Glycanase: 0.0015% by weight. First, dissolve β-glucanase and pentosanase in an appropriate amount of water to prepare solutions respectively. The concentration of the solution is 4% by weight, and place them in a constant temperature incubator at 30°C for activation; put ghee and granulated sugar into the mixture and stir Whip for 2 minutes at slow speed (level 1) in the tank, and then change to fast whipping (level 3) after stirring well, and after beating (that is, the material in the tank turns from yellow to white, it takes about 20 minutes), add eggs , ...

Embodiment 3

[0024] In the embodiment of the present invention, wheat flour: 6% by weight, almond skin powder: 26% by weight, granulated sugar: 18% by weight, ghee: 18% by weight, baking powder: 1% by weight, and eggs: 18% by weight , salt: 0.13% by weight, milk powder: 3% by weight, water: 9.8055% by weight, xanthan gum: 0.028% by weight, locust bean gum: 0.031% by weight, β-glucanase: 0.003% by weight %, pentosanase: 0.0025% by weight. First, dissolve β-glucanase and pentosanase in an appropriate amount of water to prepare solutions respectively. The concentration of the solution is 5% by weight, and place them in a constant temperature incubator at 32°C for activation; put ghee and granulated sugar into the mixture and stir Whip in the tank at slow speed (level 1) for 1.5 minutes, then change to fast whipping (level 3) after stirring well, and add eggs after beating (that is, the material in the tank changes from yellow to white, about 25 minutes) , continue to beat at medium speed (sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com