Production and reactor for polypropylene

A technology of preparation process and reaction device, which is applied in the field of polypropylene preparation process and its reaction device, can solve the problems of low grade and poor quality of products, achieve quick results, improve low-temperature brittleness, and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

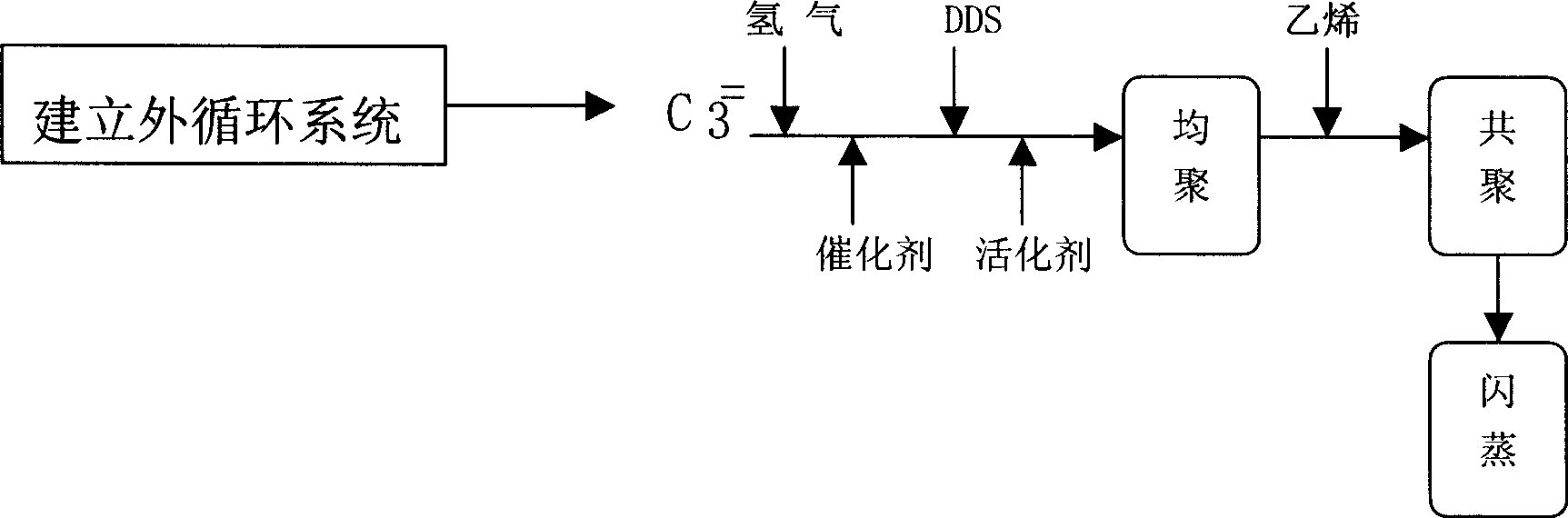

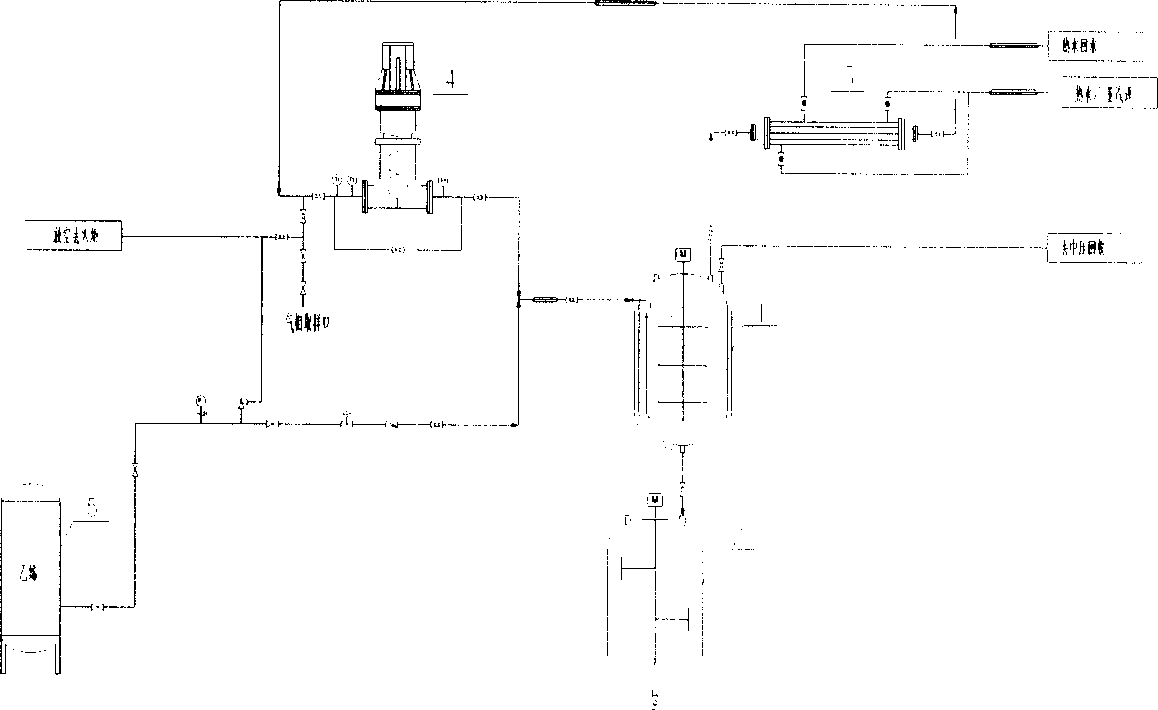

[0011] The present invention is further described in conjunction with the accompanying drawings and examples. The preparation process of the present invention includes homopolymerization, copolymerization and flashing treatment in sequence. The homopolymerization uses propylene as the main ingredient, with a trace amount of hydrogen, triethylaluminum activator, Auxiliary catalyst DDS, CS-I, CS-II catalysts are used as auxiliary materials. The auxiliary materials are carried out in the polymerization kettle 1 with propylene in a certain order. The materials used are based on one ton of polypropylene products. Base aluminum activator 0.55-0.65kg, CS-I, CS-II catalyst 0.04-0.05kg, auxiliary catalyst DDS 0.05-0.06kg, the reaction temperature is controlled at 70-80°C, the reaction pressure is controlled at 3.55-3.65Mpa, in When the homopolymerization reaction takes 70-80 minutes, open the circulating fan in the external circulation system of the polymerization kettle to feed ethylen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com