Special width fixing device for weaving lattice rings

A grid ring and compact spinning technology, applied in the textile field, can solve the problems of poor dimensional stability, uneven surface of the grid ring, inconsistent width, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

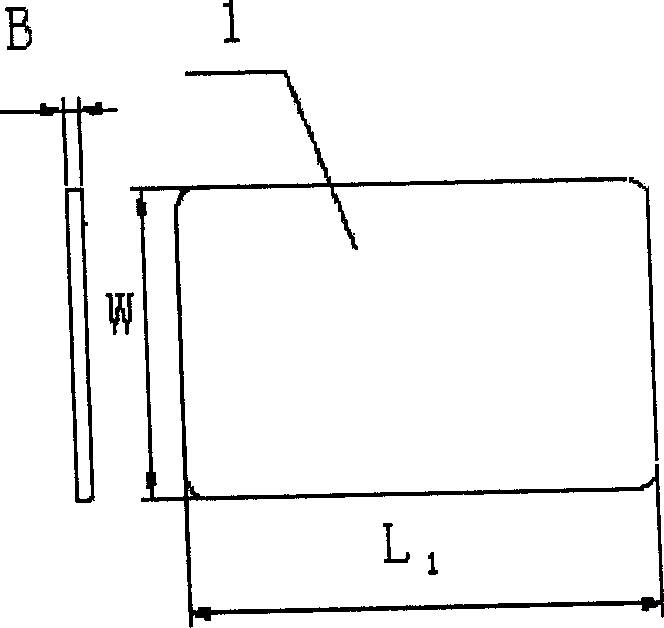

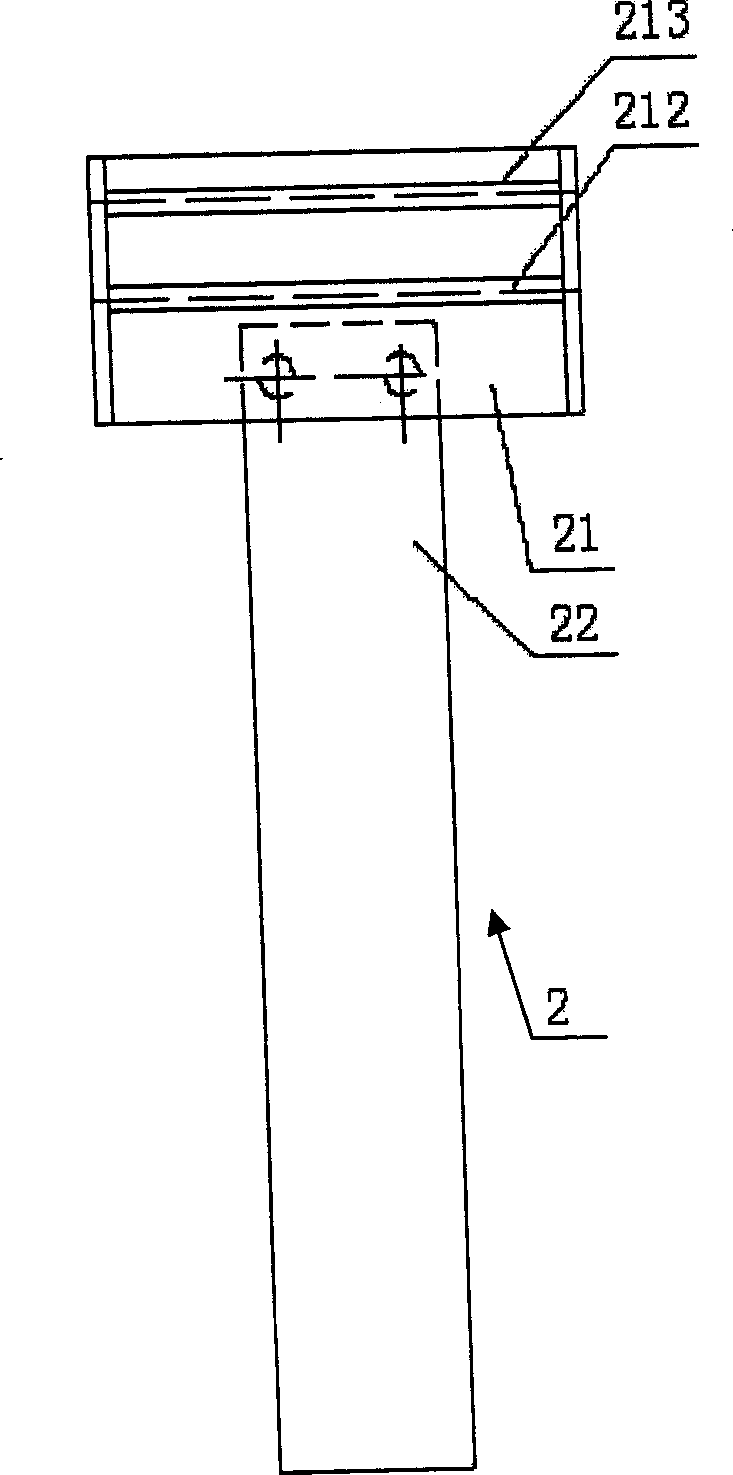

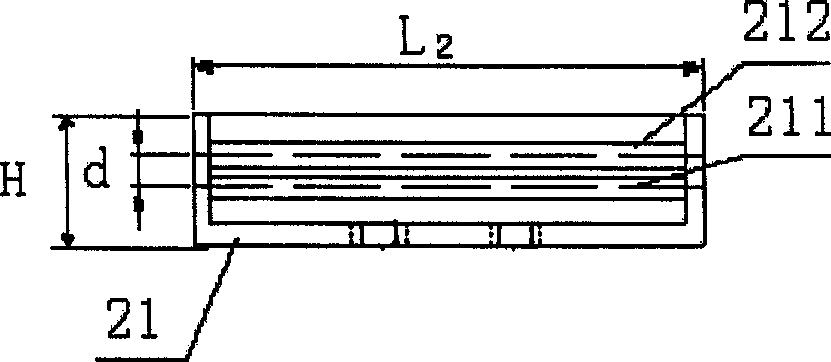

[0024] A special sizing device for weaving compact spinning grid rings, characterized in that it is composed of a sizing sheet 1 and a sizing support 2, the sizing sheet 1 plays the role of stabilizing the width of the tubular fabric, and the sizing support 2 then assists the work of the fixed film 1. Such as figure 1 As shown, the sizing sheet 1 is in the shape of a rectangular parallelepiped sheet, and the sizing sheet has a length L 1 55~65mm, the width W of the fixed sheet is 25~35mm, the thickness B of the fixed sheet is 2~4mm, it is made of stainless steel, and the surface and corners are smooth; figure 2 As shown, the frame frame 2 is composed of two parts, the frame head 21 with screw holes and the frame arm 22 with screw holes, as figure 2 , figure 2 (a), figure 2 (b), figure 2 As shown in (c), three thin iron bars parallel to each other are installed on the frame head 21 with screw holes, wherein the lower thin iron bars 211 and the upper thin iron bars 212...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com