Process for producing linear alpha olefins

A straight-chain, metal salt technology, applied in chemical instruments and methods, hydrocarbons, organic compounds/hydrides/coordination complex catalysts, etc., can solve problems such as no disclosure of straight-chain alpha-olefins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0110] The molar ratio of water to aluminum compound in the preparation of aluminoxane is preferably in the range of 0.01:1 to 2.0:1, more preferably 0.02:1 to 1.2:1, even more preferably 0.4:1 to 1:1, especially 0.5 : 1.

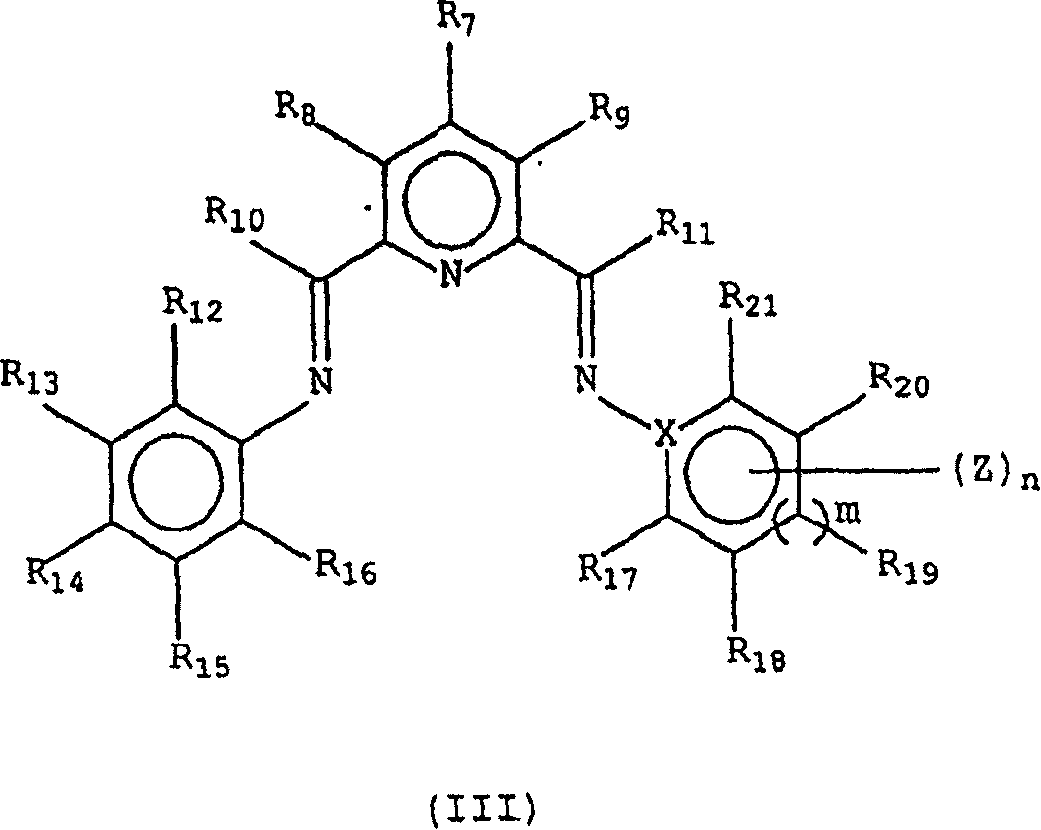

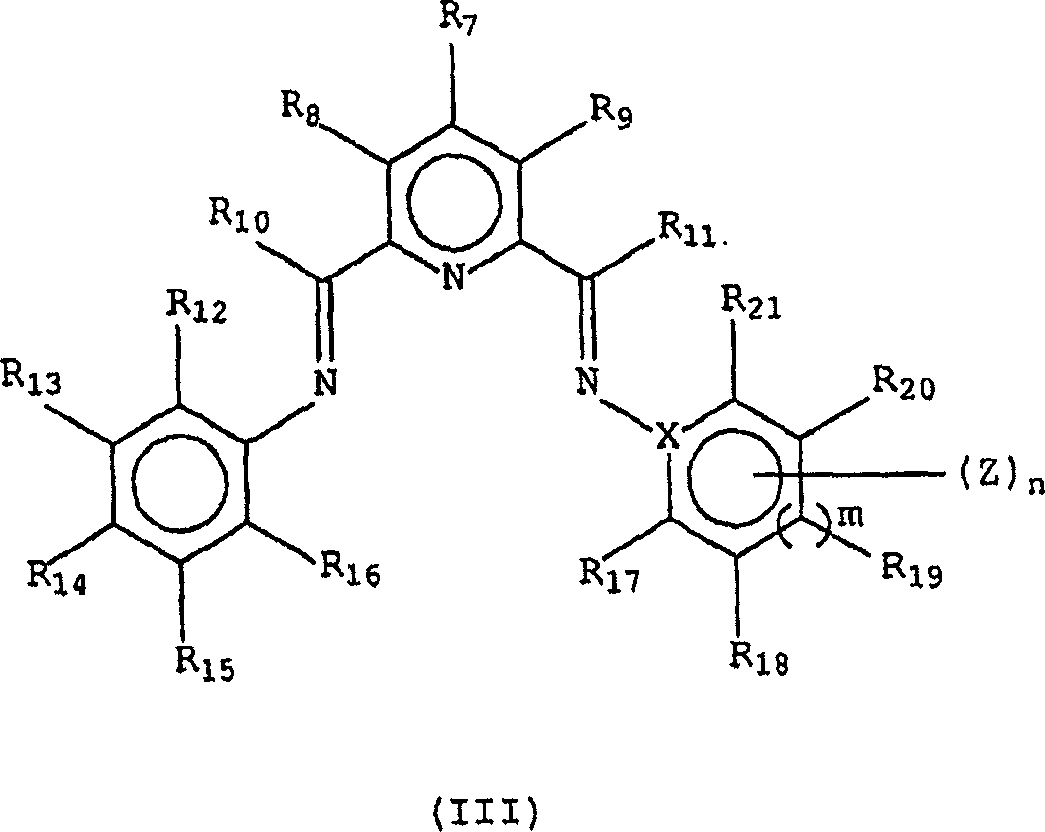

[0111] When preparing the catalyst system here in situ, it is preferred to use cocatalysts and metal salts in amounts such that the Al / Fe or Al / Co atomic ratio is in the range 0.1-106, preferably 10-10 5 , and more preferably 10 2 -10 4 . It is also preferred that the molar ratio of bisaryl imine pyridine ligand / Fe or bis aryl imine pyridine ligand / Co is in the range of 10 -4 -10 4 , preferably 10 -1 -10, more preferably 0.5-2, and especially 1.2.

[0112] Further optional components may be added to the catalyst system herein, such as Lewis acids and bases, such as those described in WO02 / 28805.

[0113] Oligomerization

[0114] The catalyst component is usually used in the oligomerization reaction mixture in such an amount that it contains 10 per m...

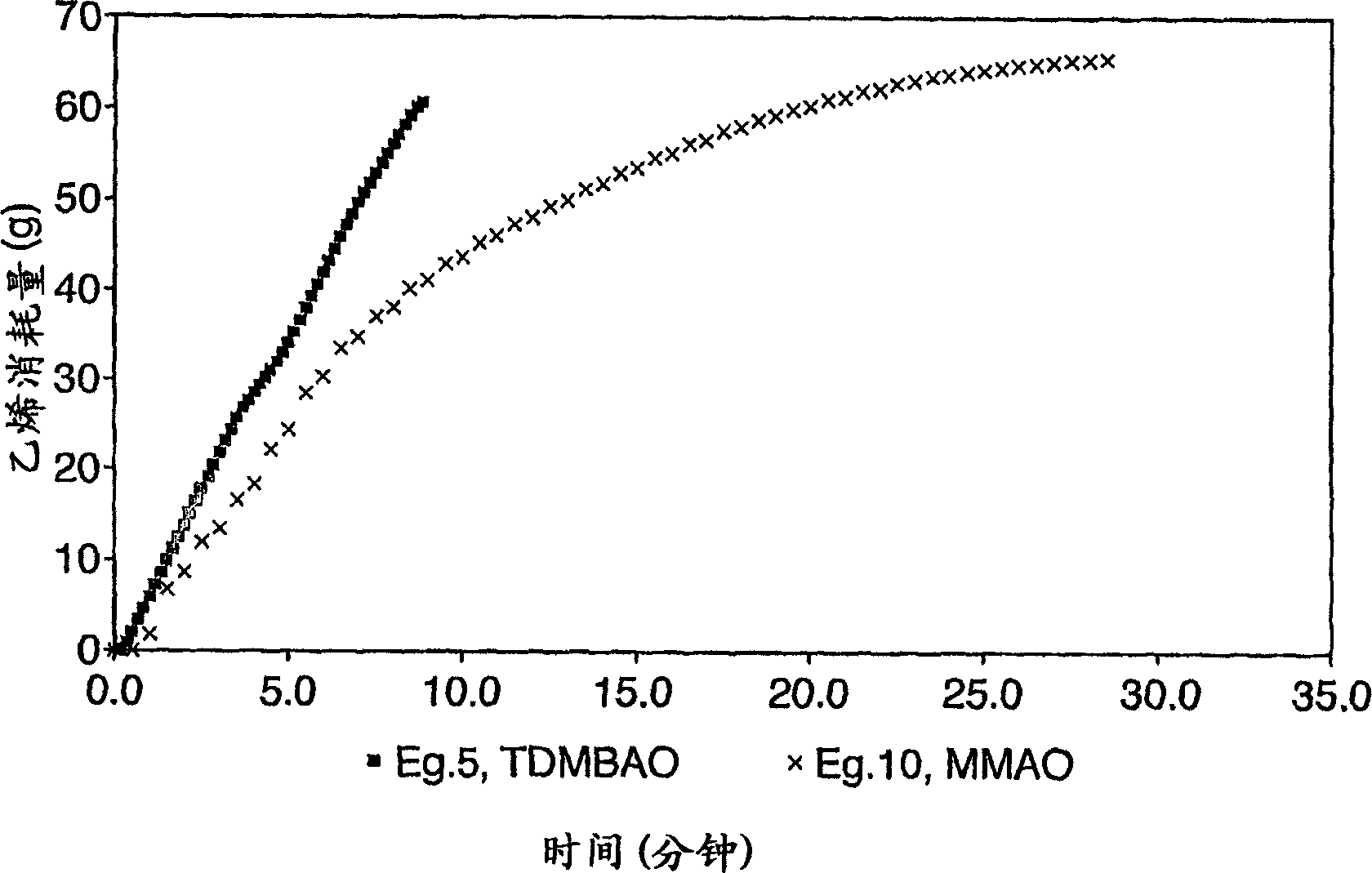

Embodiment 1-10

[0164] Oligomerization experiments 1-10 were performed in a 0.5 liter stainless steel reactor. Under an inert atmosphere, the reactor was purged at 70 °C for at least 30 minutes using 0.15 g MMAO and 125 ml anhydrous heptane. After draining the contents, 125 ml of anhydrous heptane and the indicated cocatalyst were added to the reactor, followed by adding the indicated ligand (ligand A) and Fe(2,4-pentanedi keto acid) 3 (Fe added = 0.25 μmol; Ligand / Fe molar ratio = 1.2 + / - 0.1; Al / Fe molar ratio = 700 + / - 50 unless otherwise stated), pressurized to 16 bar with ethylene (a) . Systematic additions (4ml in toluene) to the reactor were made by injection each time, followed by rinsing the system with 2 x 4ml toluene. After 2 additions of catalyst components, the total solvent content in the reactor = about 150 ml heptane / toluene = 8 / 2 (wt / wt). After the initial exotherm, the reactor was brought to 70°C as rapidly as possible while monitoring temperature, pressure and ethylene ...

Embodiment 11-19

[0166] Examples 11-19 were carried out in a 1 liter reactor using isooctane as the reactor solvent, catalyst component solvent, rinse and solvent used to prepare the aluminoxanes. Fe(2,4-Pentedionate) 3 and the amount of solvent used was twice that of the experiments carried out in Examples 1-10 described above. Thus Fe added = 0.5 μmol; total solvent content in the reactor = about 310 ml isooctane after 2 additions of catalyst components. The ligand / Fe molar ratio was the same as in Examples 1-10. Al / Fe molar ratio = 700 + / - 50 unless otherwise stated. In Example 14, the cocatalyst and ligand / Fe(2,4-pentanedione acid) were reversed 3 order of addition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com